Method for manufacturing double-faced epitaxial growth GaAs triple-junction solar cell

A solar cell and epitaxial growth technology, applied in the field of solar cells, can solve problems such as unstable cell performance, increased cell manufacturing costs, and compatibility of triple-junction solar cells, and achieve the goals of improving photoelectric conversion efficiency, simplifying the manufacturing process, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

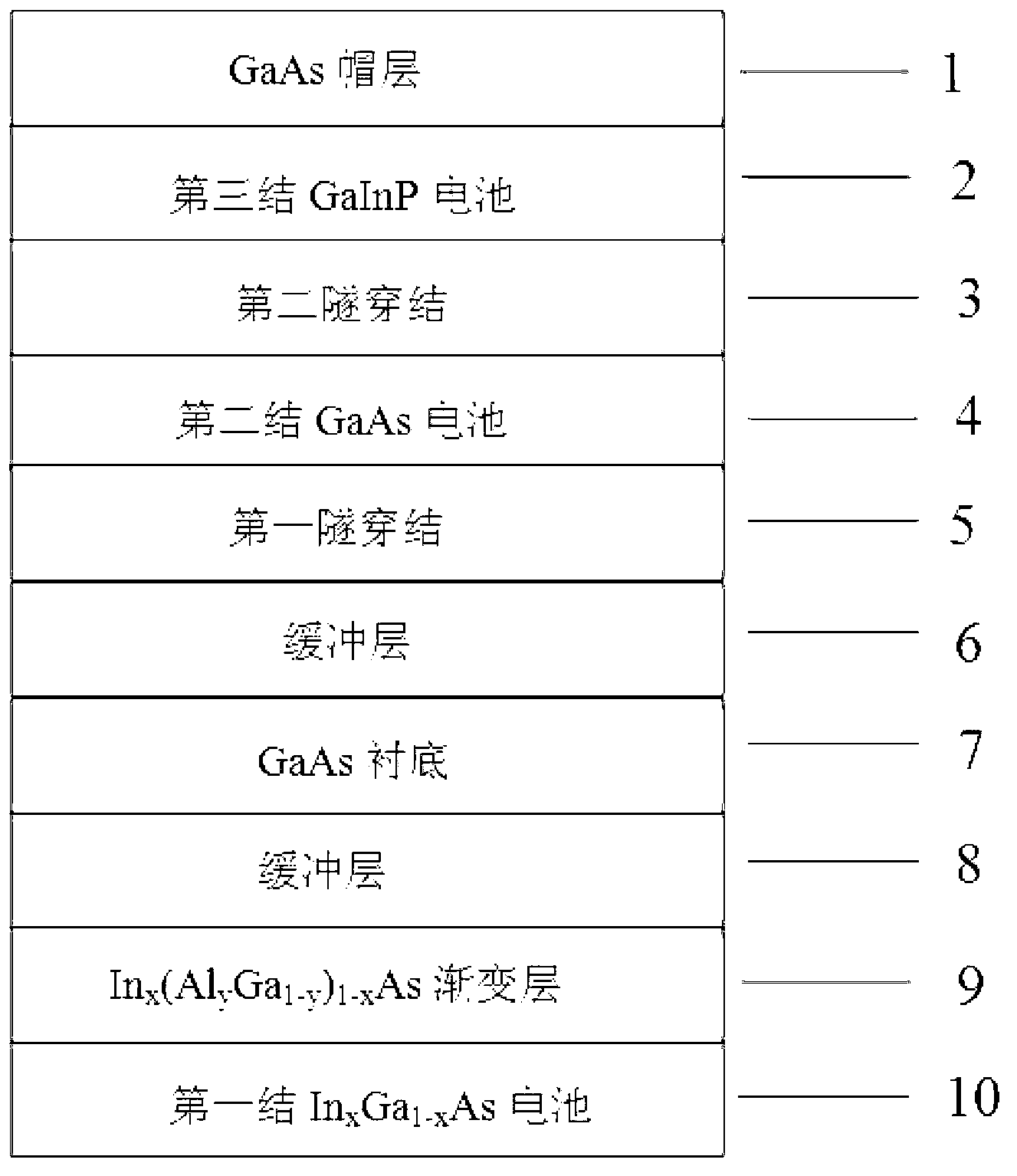

[0020] See attached figure 1 , the preparation method of double-sided epitaxial growth GaAs triple-junction solar cell of the present invention comprises the following preparation steps:

[0021] Step 1. Select the doping concentration as 1×10 18 cm -3 1. An n-type doped GaAs sheet with a thickness of 600 microns is used as the GaAs substrate 7;

[0022] Step 2. Prepare the MOCVD equipment, place the GaAs substrate in step 1 with one side up into the MOCVD operating room, set the growth temperature to 600°C, and epitaxially grow n-type doped GaAs buffer layers 8, n on the GaAs substrate in sequence. Type doped In x (Al y Ga 1-y ) 1-x As gradient layer 9 and the first junction In x Ga 1-x As battery 10;

[0023] The doping concentration of the GaAs buffer layer is 1×10 18 cm -3 , with a thickness of 0.2 microns;

[0024] The In x (Al y Ga 1-y ) 1-x In the As gradient layer, 0.03≤x≤0.3, 0.5≤y≤0.7, the doping concentration is 1×10 19 cm -3 , with a thickness of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com