R-(Fe, Co)-B sintered magnet and making method

一种烧结磁体、磁体的技术,应用在电感/变压器/磁铁制造、磁性物体、磁性材料等方向,能够解决很大波动、价格不稳定等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

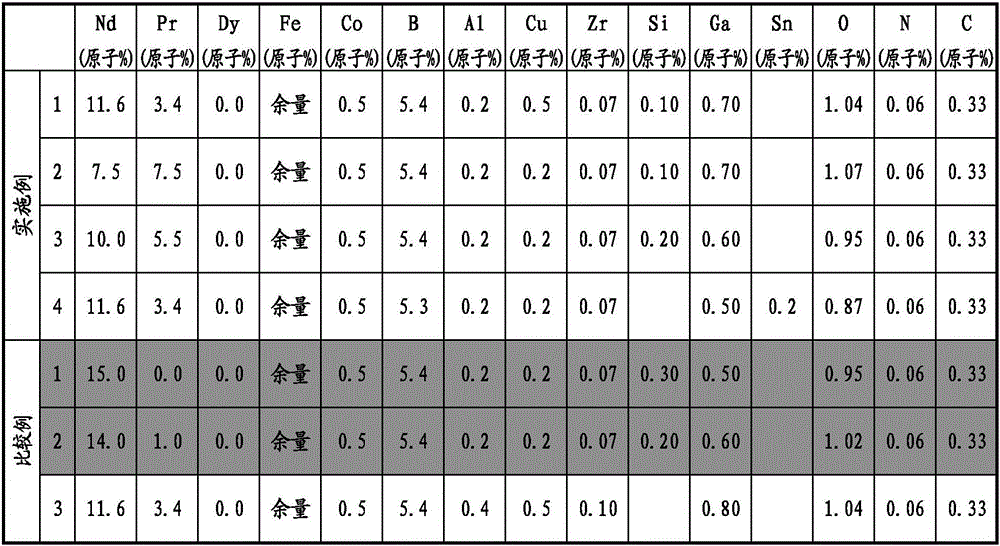

Embodiment 1-4 and comparative example 1-3

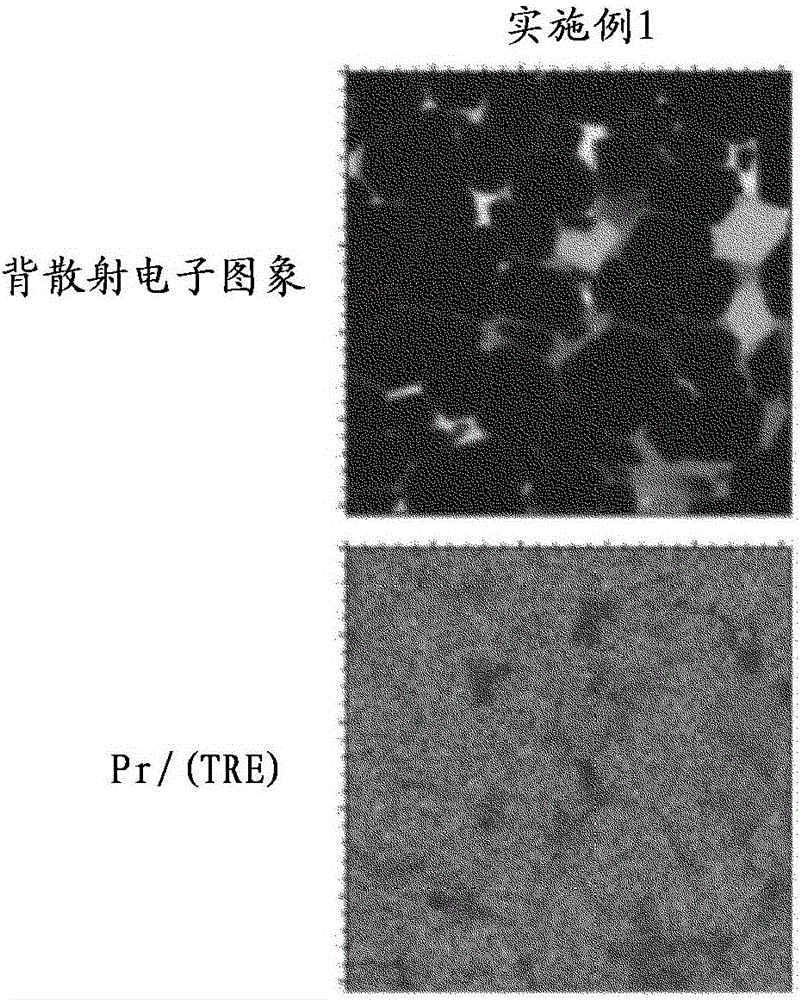

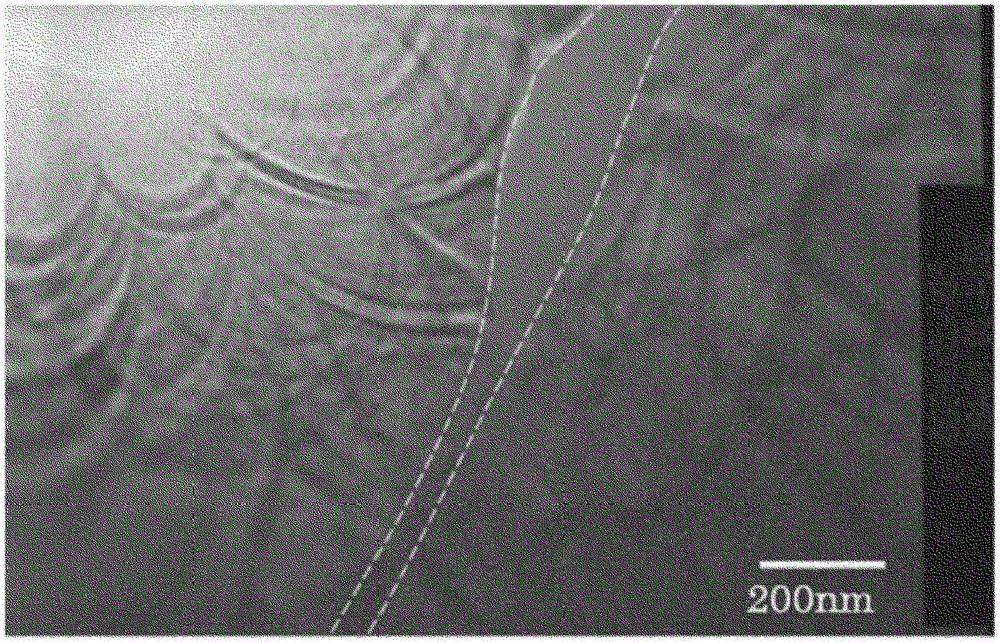

[0072] By strip casting techniques, specifically by using R metal (R is a mixture of Nd and Pr or Nd and Pr), electrolytic iron, Co, other metals and ferroboron, weighing them to meet the required composition, in Ar The alloy was melted in a high frequency induction furnace in an atmosphere and the melt was cast to prepare a 0.2-0.3 mm thick strip form. The alloy is subjected to hydrogen fragmentation, that is, hydrogen absorption at normal temperature, and then heated at 600°C in vacuum for hydrogen desorption. To the obtained alloy powder, 0.07% by weight of stearic acid as a lubricant was added and mixed. The coarse powder was finely ground to a fine powder with an average particle size of about 3 μm on a jet mill using a nitrogen stream. Under an inert gas atmosphere, the powder is loaded into the mold of the molding machine. When a magnetic field of 15 kOe was applied for orientation, the powder was compression molded in a direction perpendicular to the magnetic field. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com