High frequency induction heated temperature measuring equipment and its temperature measuring method thereof

A technology of high-frequency induction heating and high-frequency induction, which is applied in the direction of electric radiation detectors, etc., can solve problems such as uneven heating, and achieve the effects of easy operation, real-time and accurate temperature measurement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

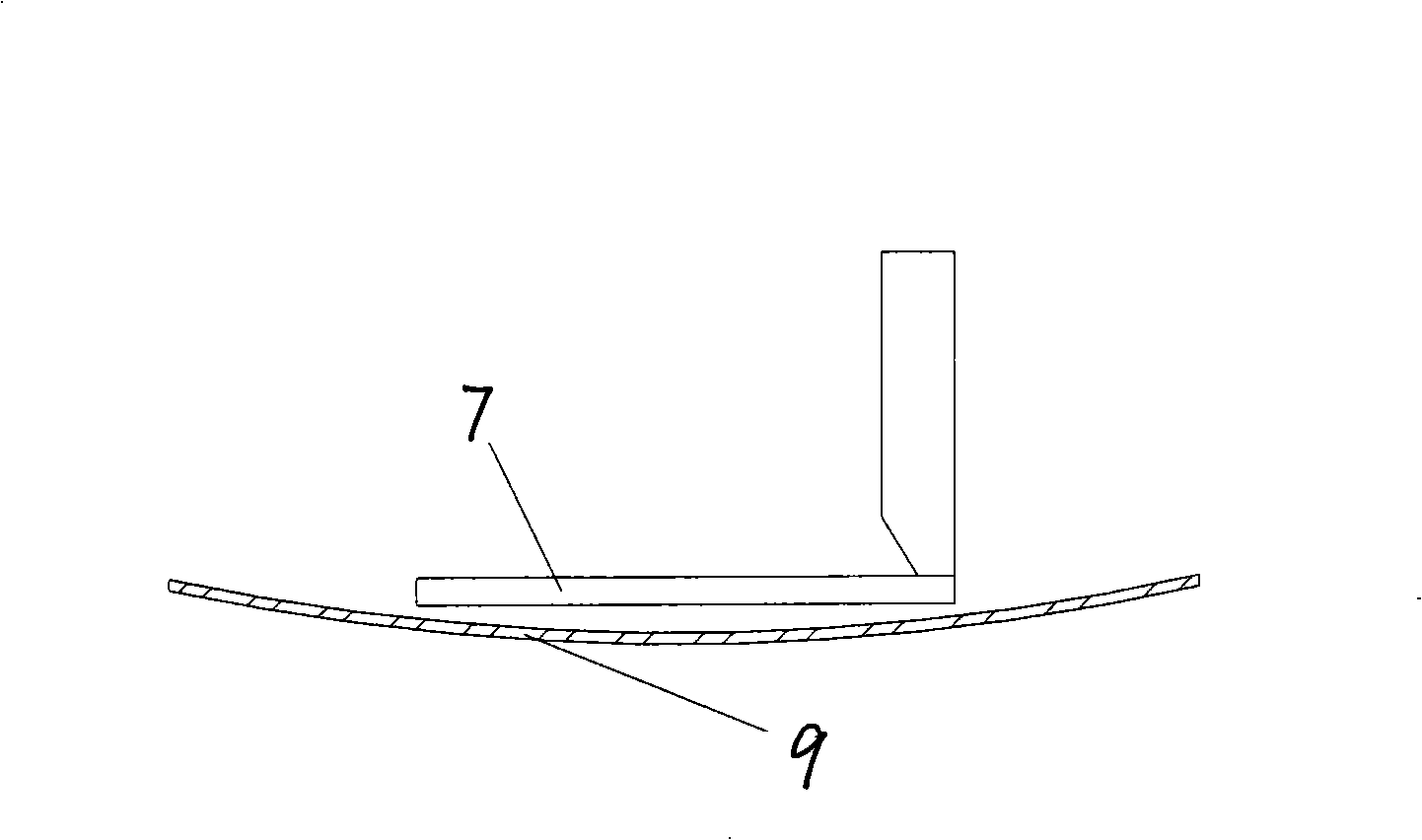

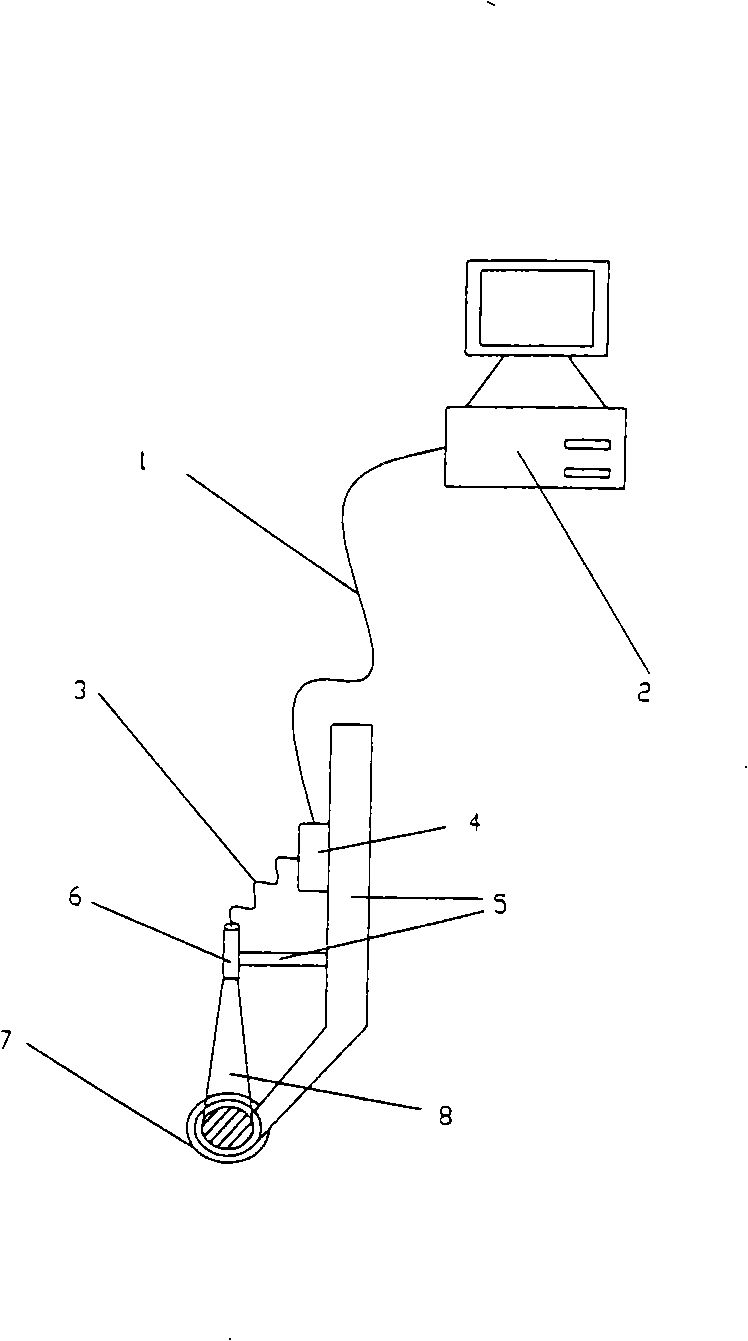

[0015] Under the effect of high-frequency induction heating of the ring coil, the flat steel plate gradually deforms due to thermal stress, and the distance between the bottom plane of the heating ring coil 7 and the steel plate 9 will change, see figure 1 . Different measuring points are selected, and the measured temperature is also different. When running on different curved surfaces, the temperature at the center of the toroidal coil 7 changes little, so the center of the heating toroidal coil 7 is selected as the measuring point of the temperature, and the measurement area is guaranteed to be within the range of the coil. Ring interior.

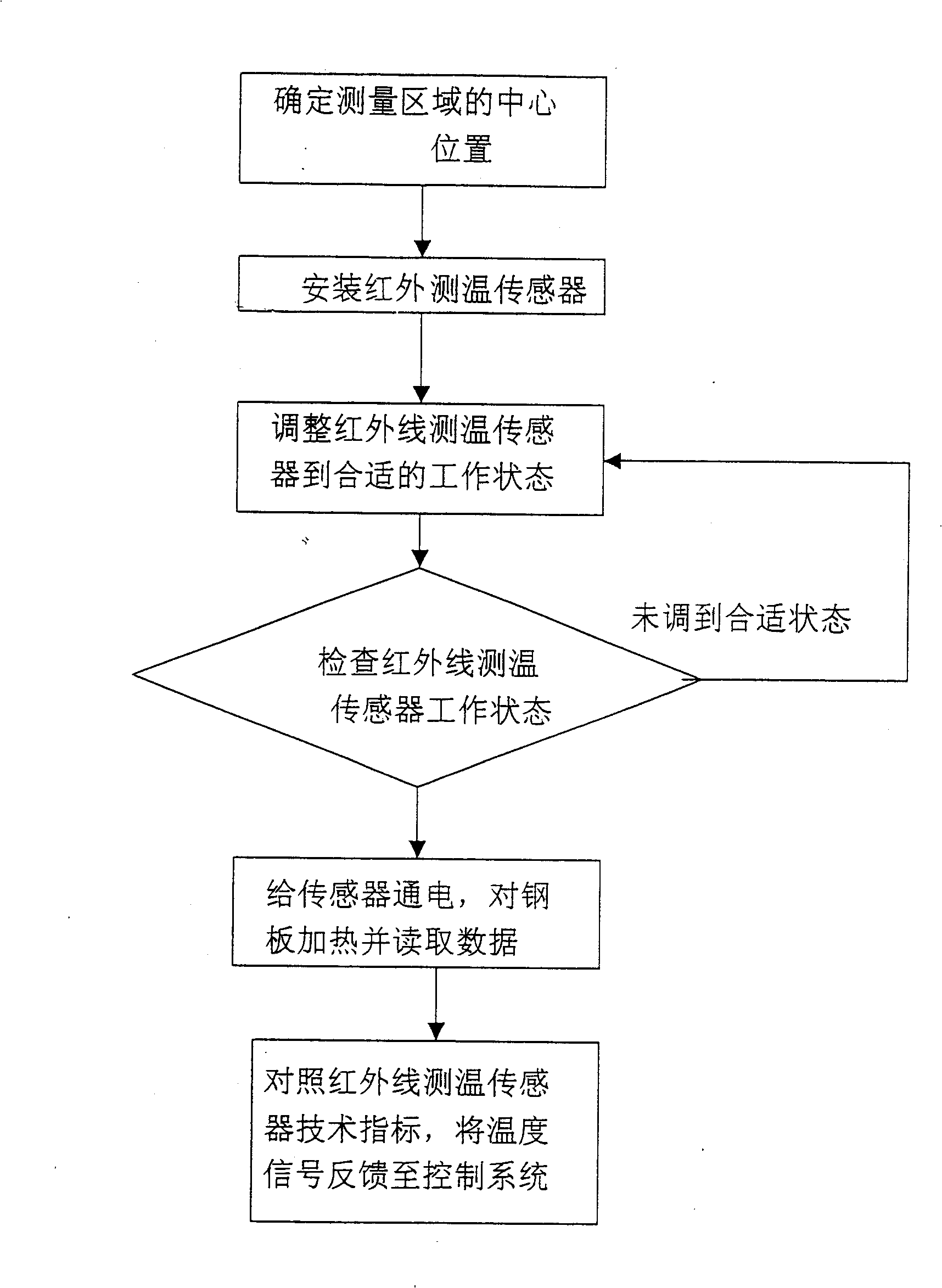

[0016] In this measurement method, the infrared temperature sensor 6 is used as a temperature detection tool, and the measurement process is as follows: figure 2 shown.

[0017] A. Determine the center positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com