High-ground-temperature surrounding rock tunnel structure simulation test device

A tunnel structure and simulation test technology, which is applied in the field of tunnel engineering, can solve problems affecting the bonding of lining structure and surrounding rock, tunnel structure damage, dehydration, etc., to improve accuracy and scientificity, uniform water flow and speed, and ensure uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

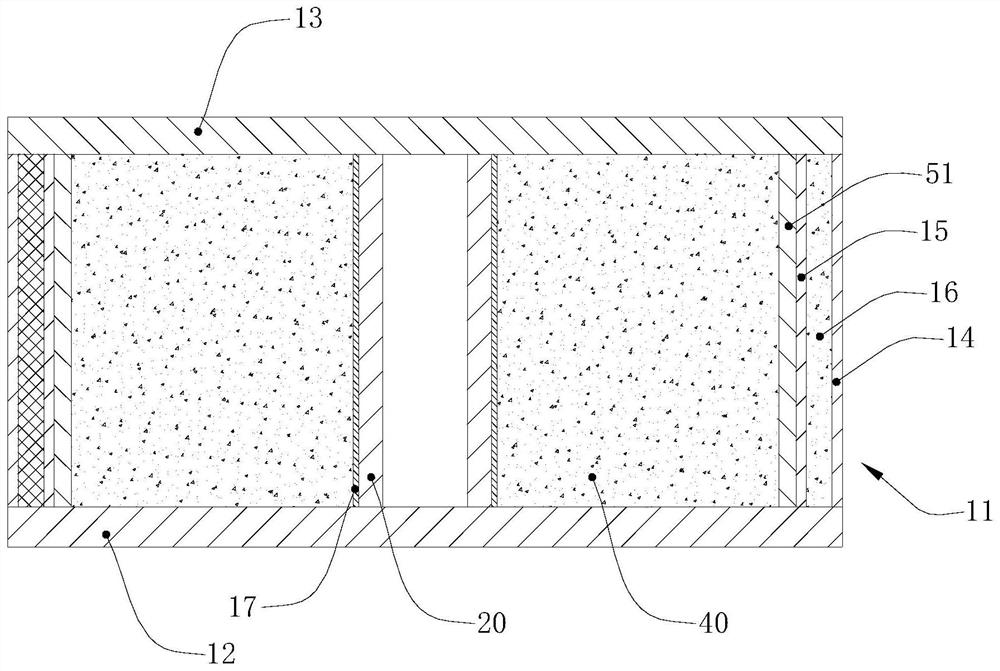

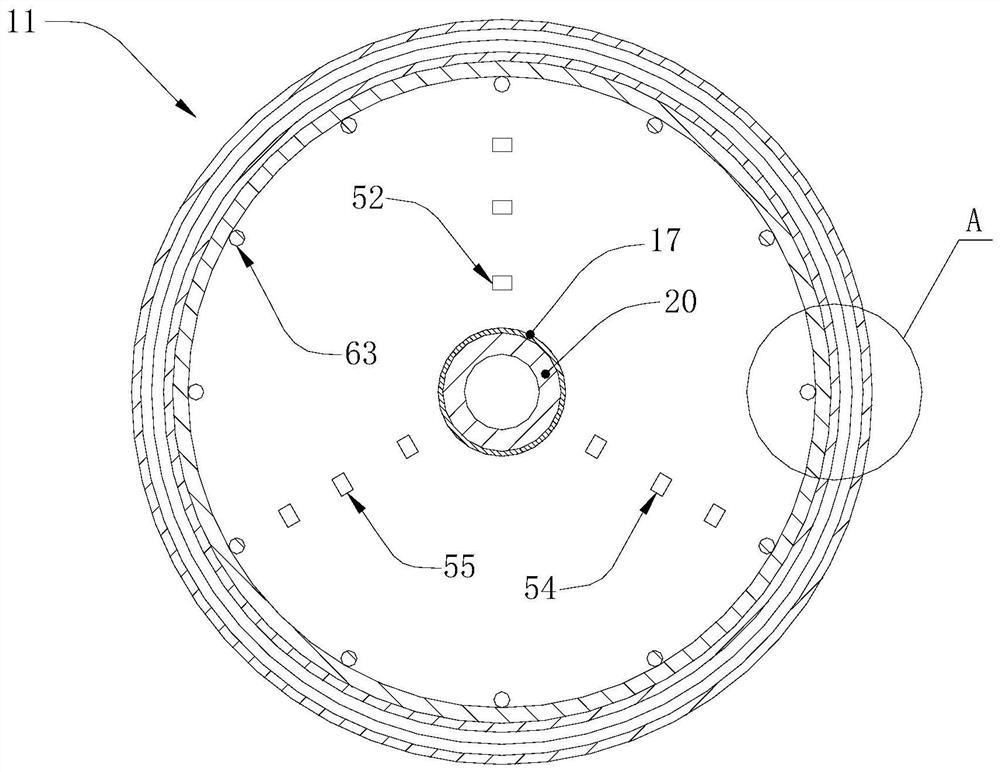

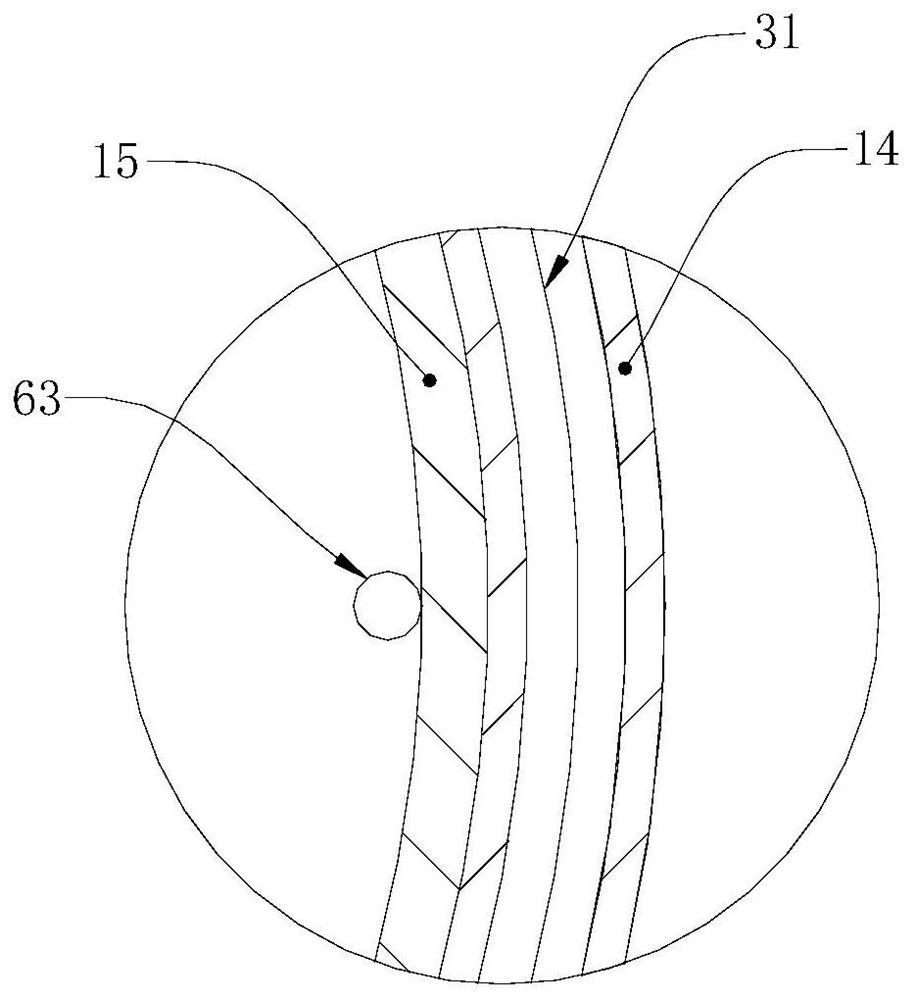

[0046] A tunnel structure simulation test device for high ground temperature surrounding rocks, comprising: a stratum simulation system, a tunnel structure simulation system 20, a high ground temperature simulation system, a data acquisition system, and a seepage simulation system. The tunnel structure simulation system 20 is set in the formation simulation system, and heat is provided by the high ground temperature simulation system. The heat is transferred from the formation simulation system to the tunnel structure simulation system 20. The seepage system simulates the groundwater flow. In order to complete the thermodynamic characteristics and heat transfer tests of the surrounding rock, the layout type and material optimization test of the tunnel insulation layer, the test of the influence of heat carried by groundwater movement on the temperature field of the surrounding rock and the thermal insulation of the tunnel, etc.

[0047] Please refer to Figure 1 to Figure 4 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com