Device and method for generating aerosol

An aerosol generation and aerosol technology, which is applied in the field of electronic cigarettes, can solve the problems of carbonization of liquid penetrating parts, low liquid conduction rate of liquid penetrating parts, and high temperature of electric heating body, and achieves the effect of avoiding carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

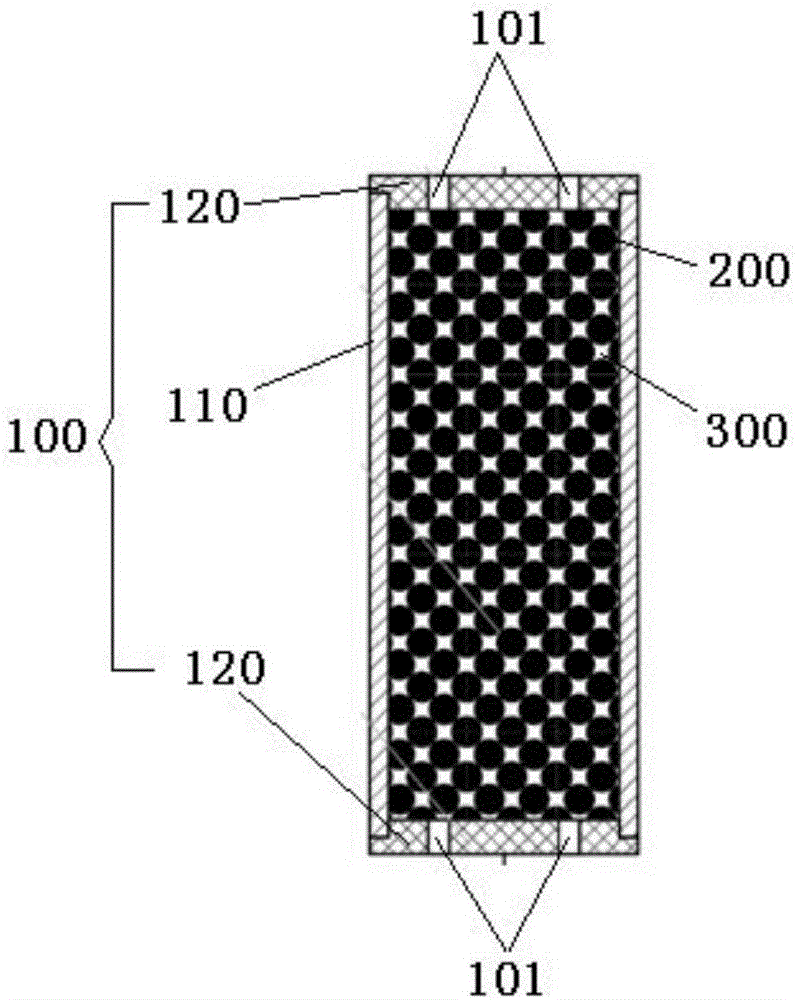

[0033] Such as figure 1 As shown, the aerosol generating device of the present embodiment includes:

[0034] The casing 100, the casing 100 is a hollow structure, and the casing 100 is provided with a ventilation hole 101;

[0035] The housing 100 includes a housing body 110 and at least two conductors 120 spaced apart on the housing body 110;

[0036] A plurality of conductive particles 200 are filled inside the casing 100, adjacent conductive particles 200 are in contact with each other, and the conductor 120 is in contact with at least one conductive particle 200;

[0037] The aerosol matrix 300 is filled inside the casing 100 , and the aerosol matrix 300 is in contact with the plurality of conductive particles 200 .

[0038] When the aerosol generating device of this embodiment is in use, after a voltage is applied to the conductor 120, an electric current passing through a plurality of conductive particles 200 is generated, and the electric current causes the plurality ...

Embodiment 2

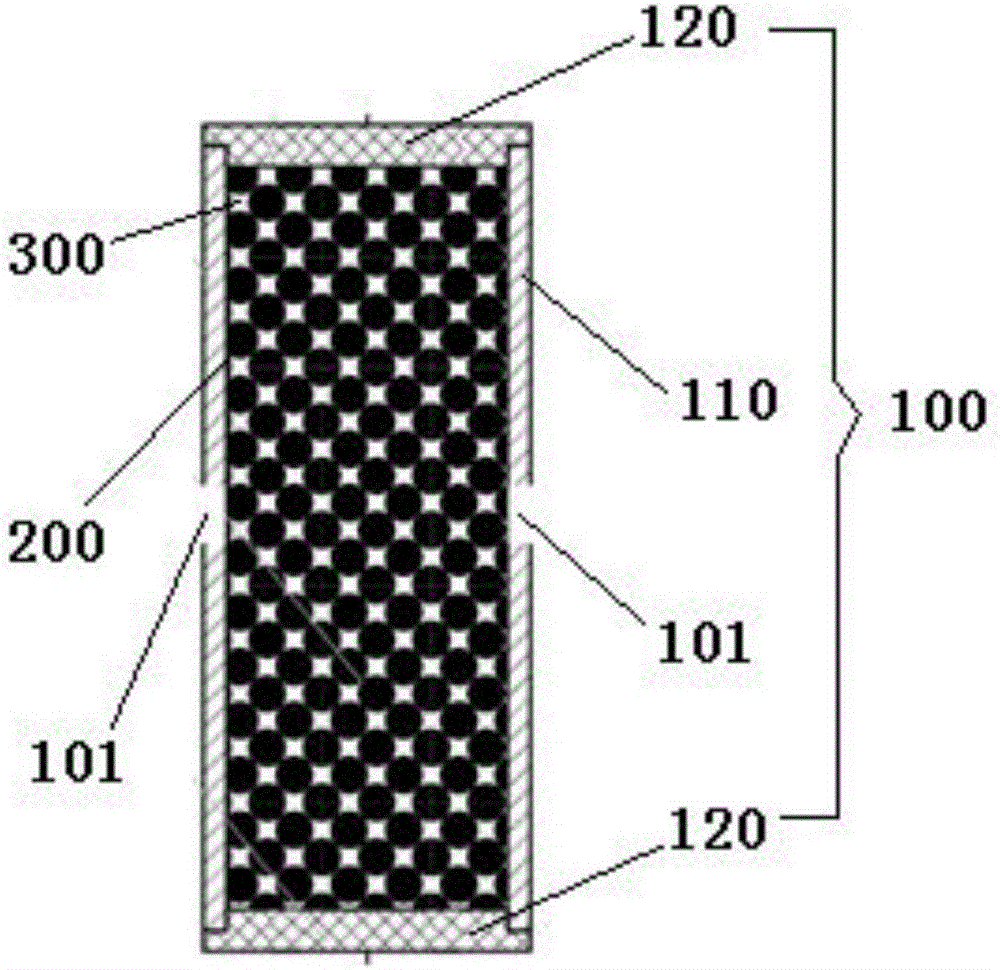

[0053] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the vent hole 101 is arranged on the shell body 110. In this embodiment, there are two vent holes 101, and the two vent holes 101 are arranged coaxially so as to facilitate the airflow to drive The aerosol is released to the outside of the housing 100 .

[0054] The conductive particles 200 in this embodiment are modified graphite particles, and the properties of the modified graphite particles are stable, which can avoid the problem of unstable heating of the conductive particles 200 to the aerosol matrix 300 .

[0055] The aerosol generating device and the aerosol generating method of the present invention use a plurality of conductive particles 200 as heating elements, the plurality of conductive particles 200 are distributed inside the housing 100, the aerosol matrix 300 contacts the surface of the conductive particles 200, and after electrification The heat of the conductive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com