Method for preheating large-size selective laser sintering sub region

A laser selective sintering and large-scale technology, which is applied in the direction of additive processing, can solve problems such as troublesome installation, complicated control, and complicated sub-area methods, so as to avoid local overheating or overcooling, ensure uniform heating temperature field, and solve heating problems. Effects of Uniformity Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A large-scale laser selective sintering sub-area preheating method, comprising the following steps:

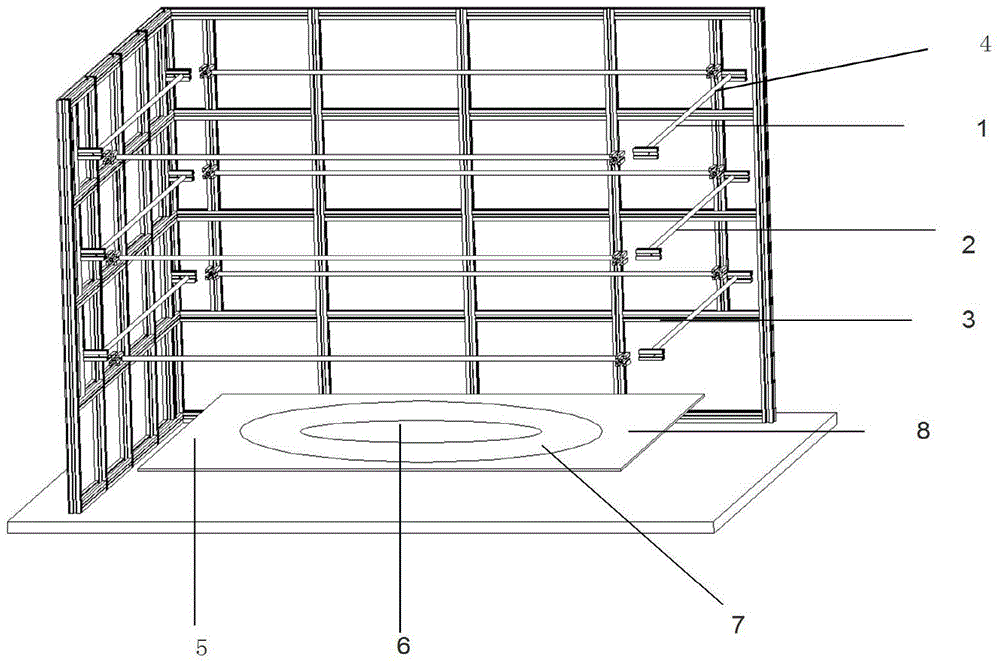

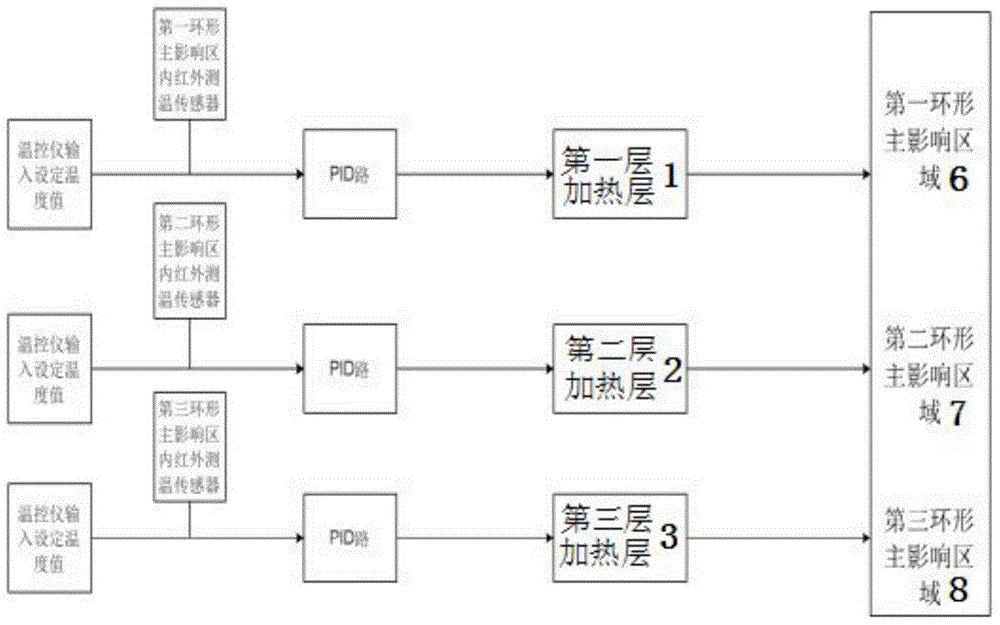

[0022] The first step is to preheat a large-sized powder bed with a heating area of 2000mm side length, divide the top of the powder bed 5 into 3 different heating layers according to different height intervals, and then adjust the height of each heating layer, As shown in the attached figure, the height of the first heating layer 1 is 400mm, the height of the second heating layer 2 is 800mm, and the height of the third heating layer 3 is 1200mm. Each heating layer is arranged with 4 heating lamps 4 A square heating array composed of;

[0023] In the second step, the powder bed is automatically divided into three annular heating main influence areas according to the three heating layers, which are respectively the first annular main influence area 6 corresponding to the first heating layer 1 in the powder bed body 5, and the second The layer heating layer 2 correspon...

Embodiment 2

[0027] A large-scale laser selective sintering sub-area preheating method, comprising the following steps:

[0028] The first step is to preheat a large-sized powder bed with a heating area of 1500mm side length, divide the top of the powder bed into two different heating layers according to different height intervals, and then adjust the height of each heating layer. The height of the first heating layer is 500mm, the height of the second heating layer is 1200mm, and each heating layer is arranged with a square heating array composed of 4 heating lamp tubes 4;

[0029]In the second step, the powder bed body is automatically divided into two annular heating main influence areas according to the two heating layers, respectively, the first heating layer is in the first annular main influence area corresponding to the powder bed body, and the second heating layer is in the The corresponding second annular main influence area in the powder bed body, the superposition of the ring...

Embodiment 3

[0033] A large-scale laser selective sintering sub-area preheating method, comprising the following steps:

[0034] The first step is to preheat a large-sized powder bed with a heating area of 2500mm side length, divide the top of the powder bed into 3 different heating layers according to different height intervals, and then adjust the height of each heating layer. The height of the first heating layer is 500mm, the height of the second heating layer is 1000mm, and the height of the third heating layer is 1500mm. The first heating layer and the second heating layer are arranged in a square composed of 4 heating lamps 4 Heating array, the third heating layer arranges a double heating array with 8 lamp tubes arranged in layers;

[0035] In the second step, the powder bed body is automatically divided into three annular heating main influence areas according to the three heating layers, which are respectively the first annular main influence area corresponding to the first hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com