Preparation method of phosphorus removal adsorbent

A phosphorus adsorbent and modifier technology, applied in chemical instruments and methods, adsorption water/sewage treatment, silicate, etc., can solve problems such as poor phosphate adsorption performance and modifiers that are not environmentally friendly, and achieve expansion Use, strong regeneration ability, strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

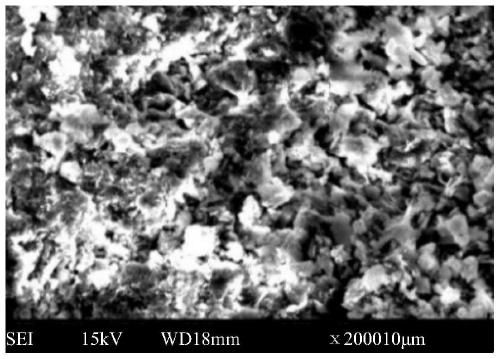

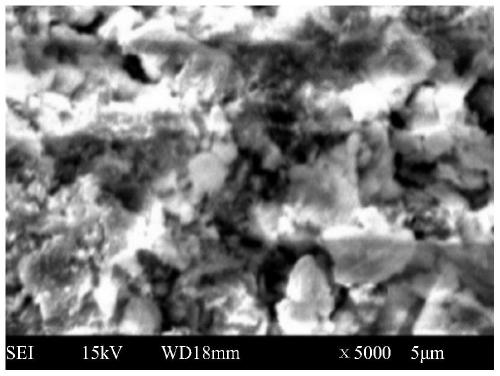

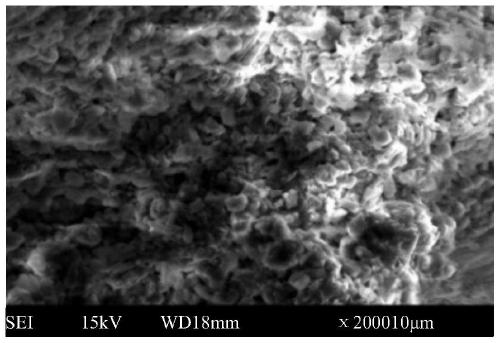

[0048] The aluminum sludge obtained from the urban water supply plant was stored in a refrigerator (4°C) for later use.

[0049] Aluminum sludge is a by-product produced after coagulation and precipitation of aluminum salt or aluminum polymer as the main coagulant in urban water supply plants. After centrifugal dehydration, the TS is 15.36g·L -1 ~16.84g·L -1 , the aluminum content in the aluminum sludge accounts for about 16.38% of its dry weight.

[0050] At 25°C, add concentrated sulfuric acid to the aluminum sludge, adjust the pH of the aluminum sludge to 1.5, put it into a constant temperature shaking incubator, set the stirring speed at 150rpm, and mix for 15-90min;

[0051] At 25°C, add concentrated sulfuric acid to the aluminum sludge, adjust the pH of the aluminum sludge to 1.5, put it into a constant temperature shaking incubator, and stir at a stirring speed of 90, 120, 150, 180, and 200 rpm for 60 minutes;

[0052] At 25°C, add concentrated sulfuric acid to the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com