Method for improving humidifying capacity of diatomite

A technology of diatomite and humidity control, applied in the field of daily chemicals, can solve the problems of restricting the development of the field of humidity control, and achieve the effect of increasing the saturated moisture absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

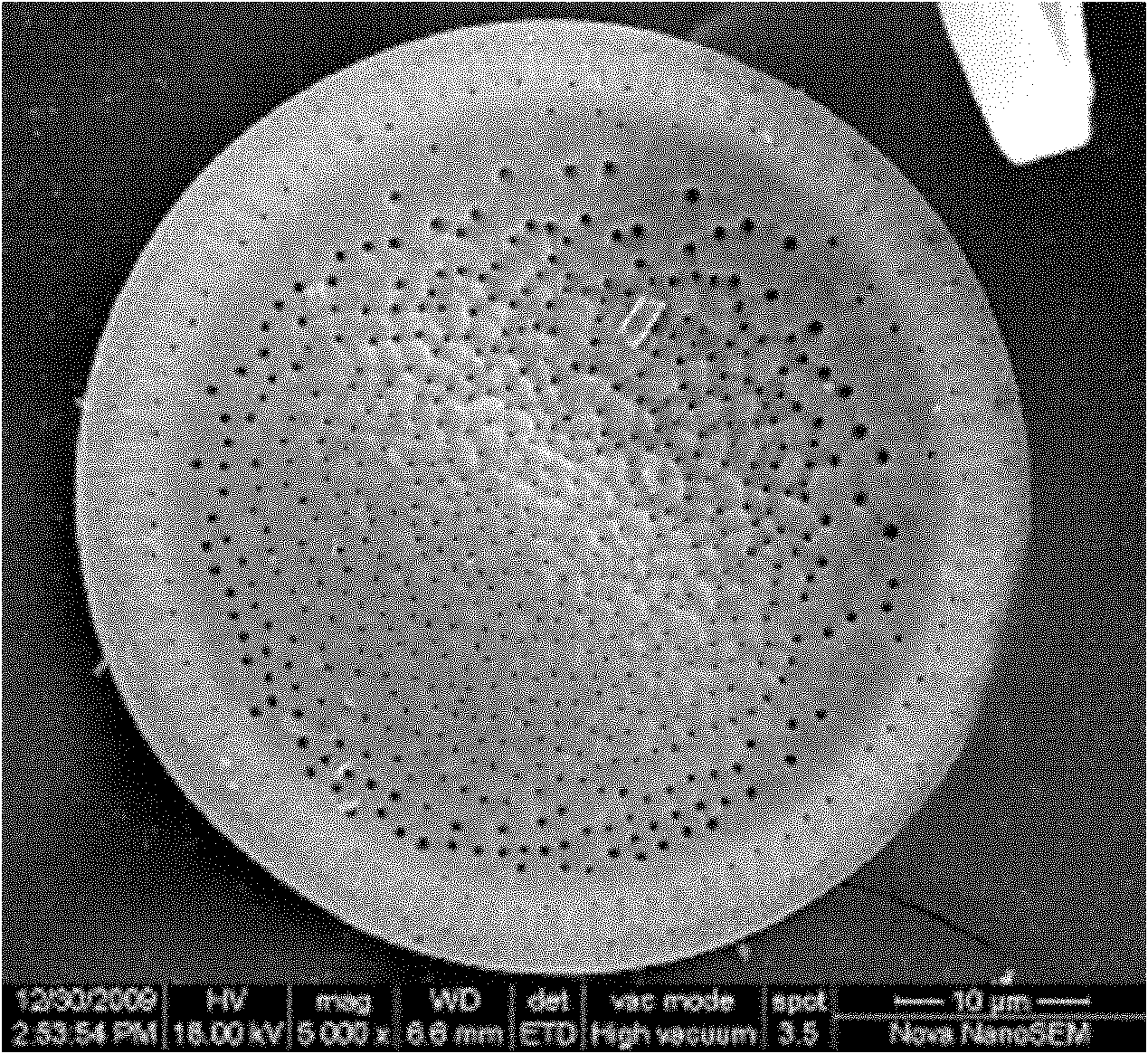

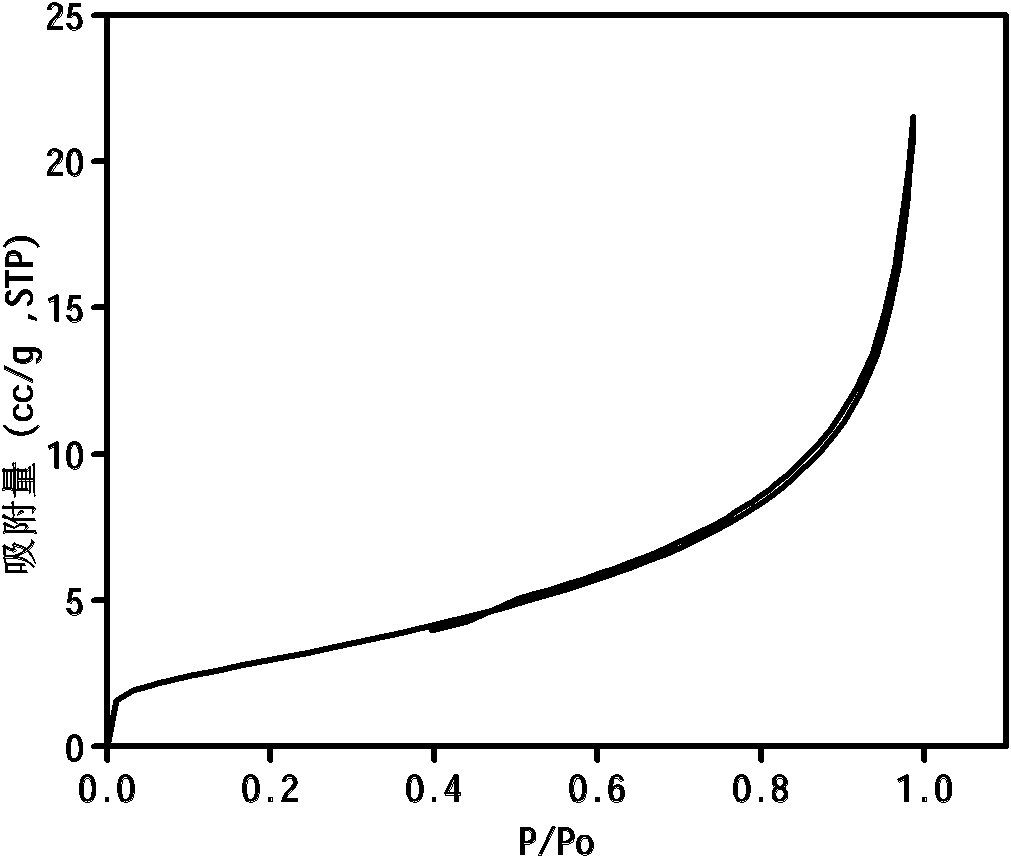

Image

Examples

example 1

[0022] Example 1 lithium chloride-diatomaceous earth humidity control material

[0023] Diatomite and 10% lithium chloride aqueous solution are reacted at 50° C. for 30 minutes at a mass ratio of 1:3, and the lithium chloride-modified diatomite humidity-conditioning material of the present invention is obtained after suction filtration and drying. The tonality performance is: in a constant temperature and humidity environment with T=20°C and relative humidity RH=88%, its saturated moisture absorption rate is 98%; in a constant temperature and humidity environment with T=20°C and relative humidity RH=15% , The saturation dehumidification rate is 12.1%.

example 2

[0024] Example 2 lithium chloride-diatomaceous earth humidity control material

[0025] Diatomaceous earth and lithium chloride aqueous solution with a mass fraction of 30% were reacted at 80° C. for 30 minutes at a mass ratio of 1:5, and after suction filtration and drying, the lithium chloride-modified diatomite humidity-conditioning material of the present invention was obtained. The tonality performance is: in a constant temperature and humidity environment with T=20°C and relative humidity RH=88%, its saturated moisture absorption rate is 110%; in a constant temperature and humidity environment with T=20°C and relative humidity RH=15% , The saturation dehumidification rate is 14.3%.

example 3

[0026] Example 3 sodium chloride-diatomaceous earth humidity control material

[0027] Diatomite and 30% sodium chloride aqueous solution with a mass fraction of 1:5 were reacted at 60° C. for 30 minutes, and the calcium chloride-modified diatomite humidity-conditioning material of the present invention was obtained after suction filtration and drying. Humidity control performance: in a constant temperature and humidity environment with T=20°C and relative humidity RH=88%, the saturated moisture absorption rate is 27%, and in a constant temperature and humidity environment with T=20°C and relative humidity RH=15%, The saturation dehumidification rate was 3.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com