Electromagnetic induction heating 3D printing extrusion head and method

A technology of electromagnetic induction heating and 3D printing, applied in the processing of heating elements, 3D object support structures, additive manufacturing, etc., can solve the problem of reduced model accuracy and strength, low temperature control accuracy, no 3D printing extrusion head and method and other problems, to achieve the effect of high strength and precision, uniform and stable heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

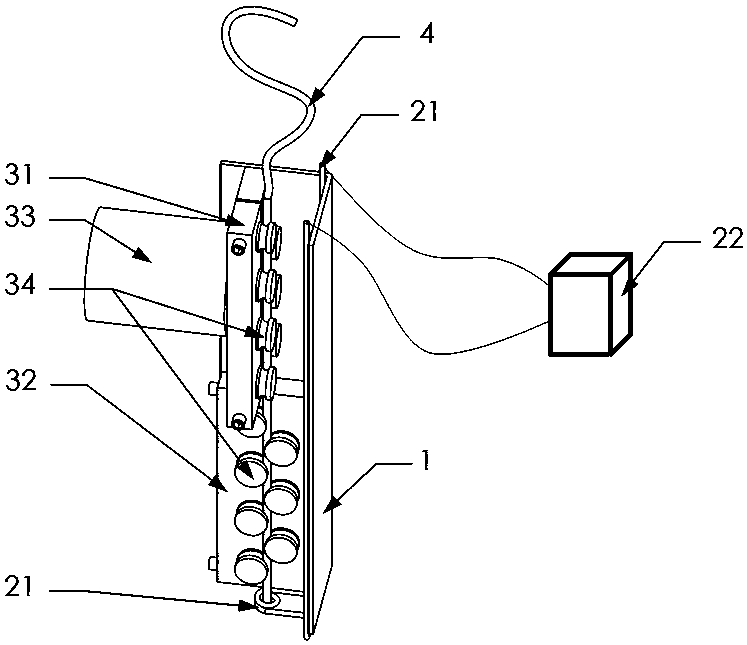

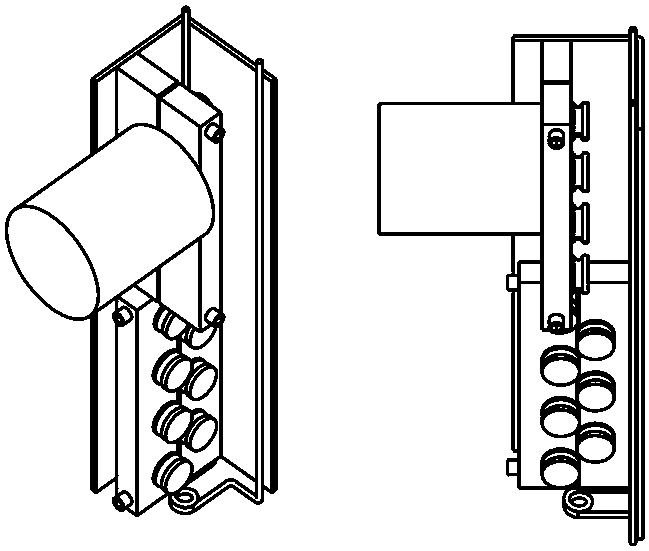

[0018] The present invention provides an electromagnetic induction heating 3D printing extrusion head and method, including a bracket 1, an electromagnetic induction heating coil 21 and a set of wire feeding mechanism 3 with straightening function, electromagnetic induction heating coil 21 and wire feeding mechanism 3 Fixedly installed on the bracket 1. The wire 4 enters the wire feeding mechanism 3 through the upper guide wheel 34 of the wire feeding mechanism 3, the wire feeding mechanism guide wheel 34 is driven by the motor 33 to convey the wire 4 downward, and the lower guide wheel 34 outputs the wire 4 to the electromagnetic heating coil 21 in. For non-metallic wire materials, it is necessary to increase the metal bushing embedded in the electromagnetic induction heating coil. The pulse generator 22 makes the electromagnetic induction heating coil generate an alternating electromagnetic field, and the wire material 4 is used for deposition and molding after being heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com