Spray nozzle flame heating device for casting die

A flame heating and casting mold technology, applied in the field of metallurgical casting, can solve problems such as inconvenient operation, potential safety hazards, overheating of mold cavity, etc., achieve safe and convenient operation, avoid mold damage, and ensure casting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

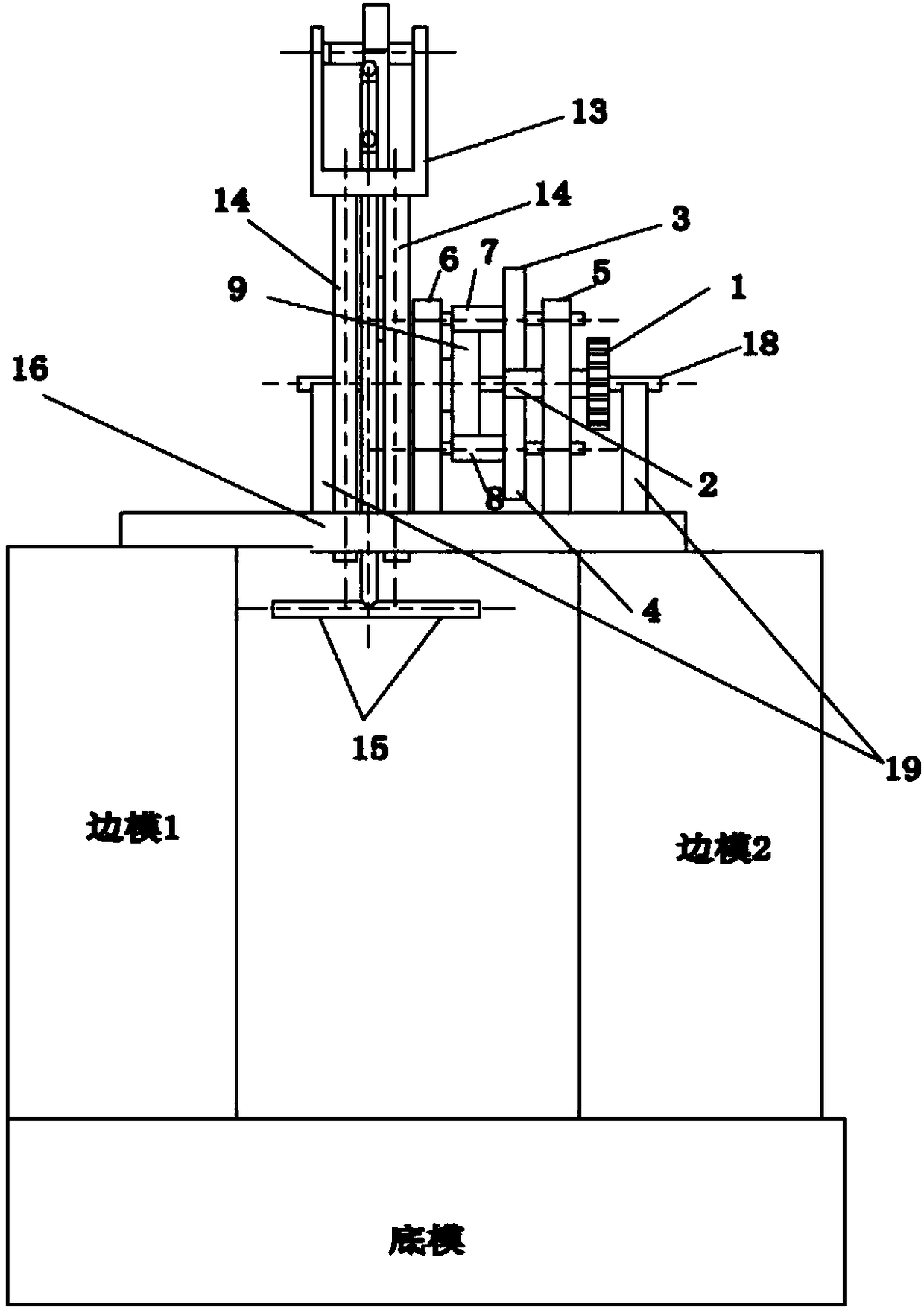

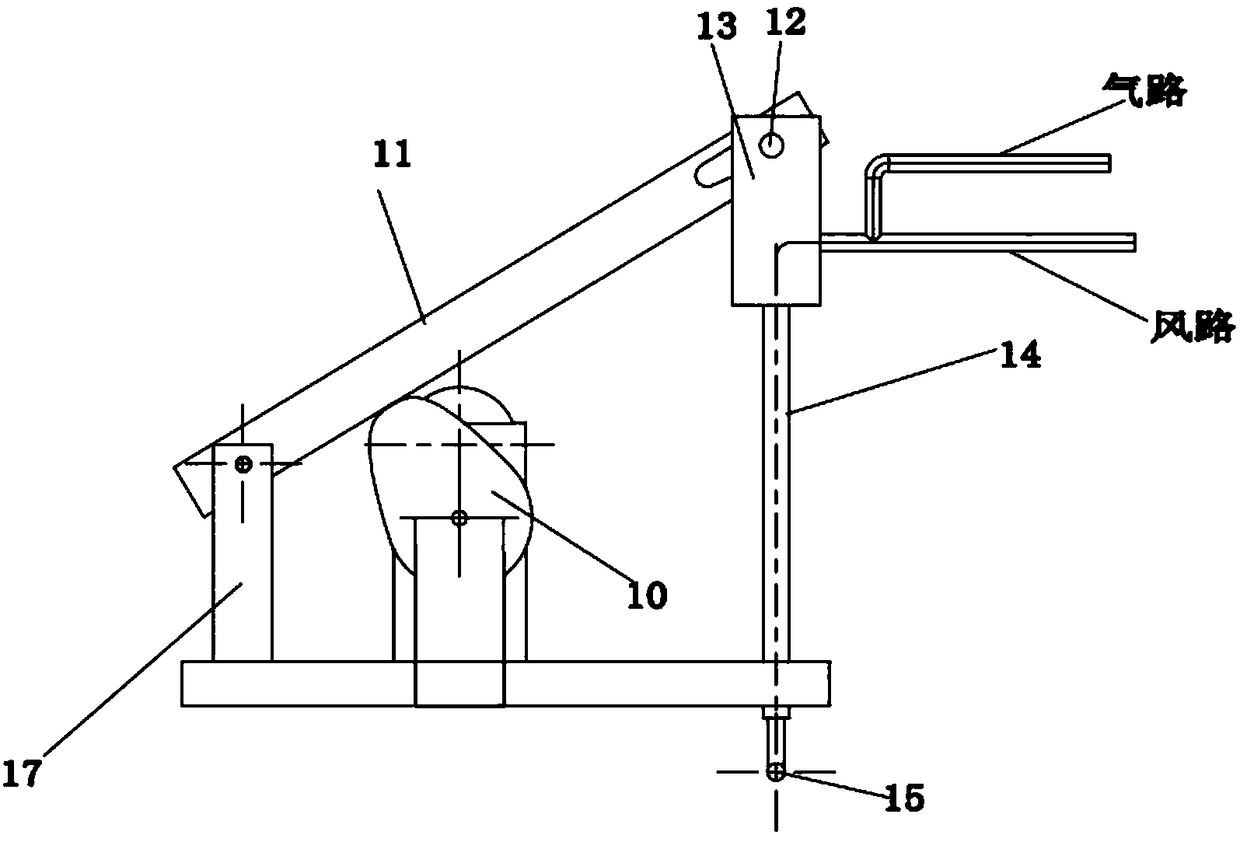

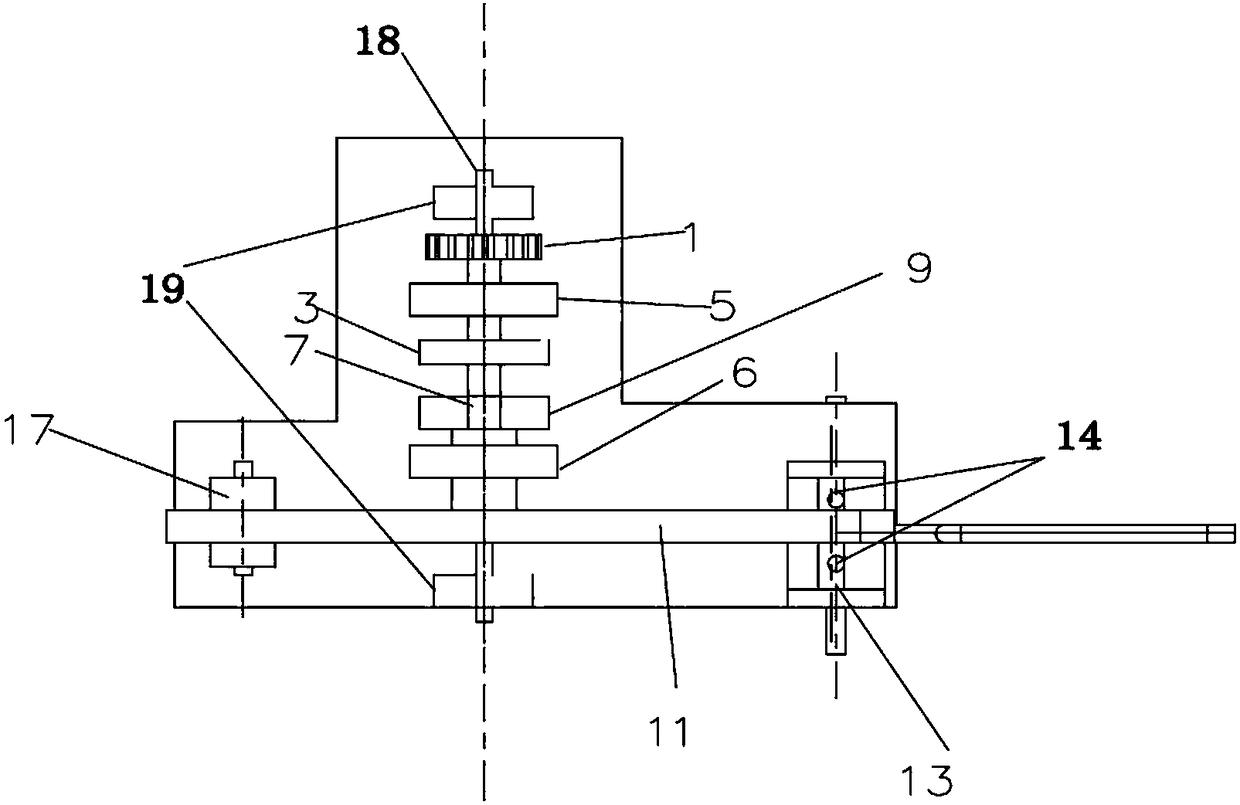

[0011] The casting mold nozzle flame heating device of the present embodiment is as Figure 1 to Figure 3 As shown, when in use, one end of the base 16 placed above the mold is hinged to one end of the swing bar 11 through the stand 17, and the other end of the base 16 forms a vertical movement pair with the guide column 14 fixed to the flame nozzle 15 at the lower end. The fixed mounting plate 13 at the upper end constitutes a moving pair along the length direction of the chute through the chute at the other end of the bearing pin 12 and the fork 11 . The flame nozzle 15 is externally connected with a gas path and a wind path for transporting combustible gas and oxygen respectively. Between the stand 17 and the guide column 14, there are two side cam brackets 19 fixed on the base 16, and the cam bracket 19 supports the rotatable cam 10 that forms a cam pair with the middle part of the fork 11 through the rotating shaft 18. The cam bracket 19 also supports the wind-driven imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com