Fish steaming container and steam heating type cooking instrument

A container and fish steaming technology, which is applied in the field of kitchen appliances, can solve the problems of hardening of the back of the fish body, destroying the taste of the fish, and reducing the efficiency of steaming fish, so as to achieve the effects of uniform heating, shortening cooking time, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

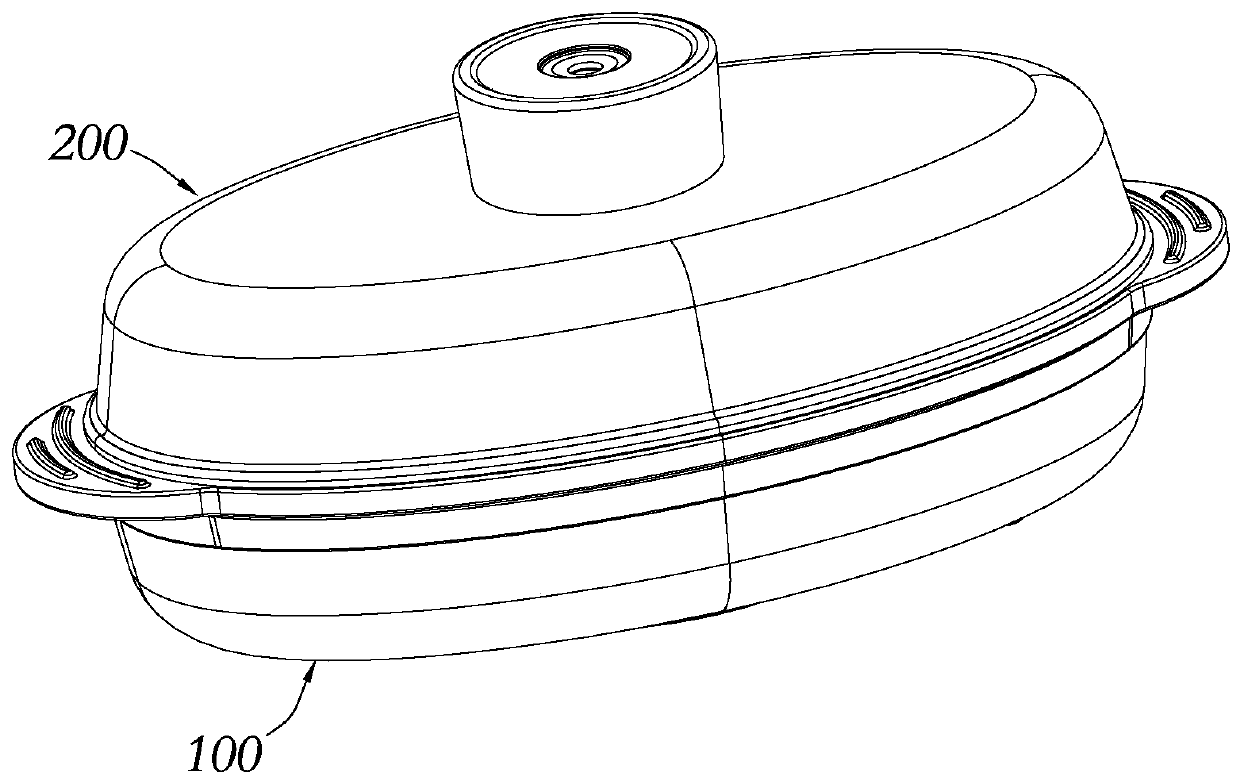

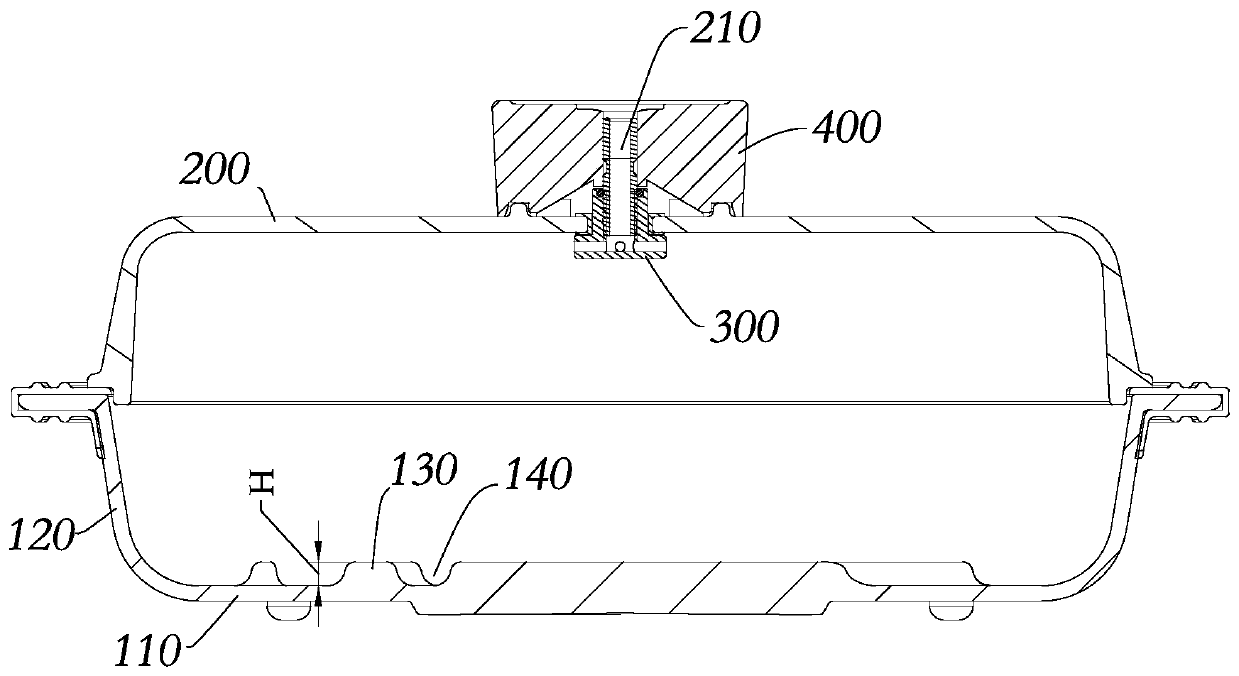

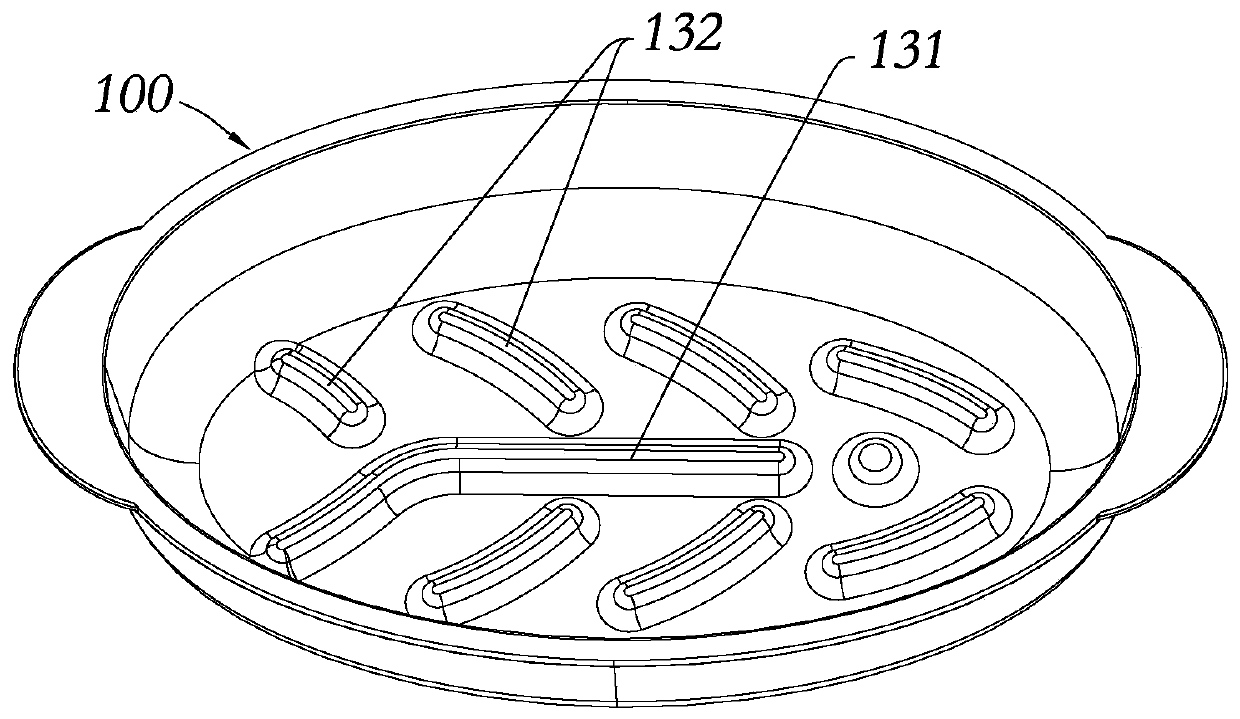

[0046] The present invention proposes a fish steaming container, comprising a tray body and a tray cover, the tray body and the tray cover cooperate to form a steam cavity, and the tray cover has a steam input channel for steam to pass into the steam cavity, so The disc surface of the disc body is provided with a raised portion carrying the fish body, and the raised portion forms a gap between the fish body and the disc surface for steam to enter, and the formation of the gap enables the steam to heat in all directions Fish body, the fish body is heated more comprehensively and evenly, thereby solving the problem of uneven heating existing in the existing fish plate steamed fish, and can improve cooking efficiency and shorten cooking time.

[0047]The technical solutions of the embodiments of the present invention will be explained and described below in conjunction with the accompanying drawings of the embodiments of the present invention, but the following embodiments are onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com