Roller type heat-conducting oil heating system of digital sizing machine

A heating system and heat transfer oil technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve problems such as affecting the quality of fabrics, unfavorable printing, uneven heating, etc., to save manpower, flexible use, Uniform and stable heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

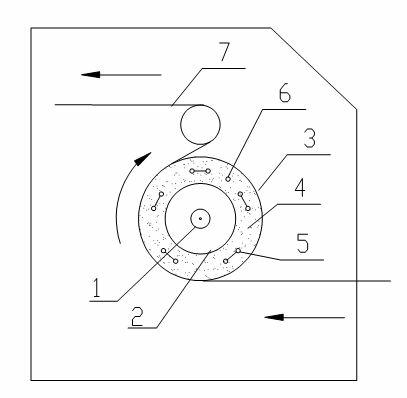

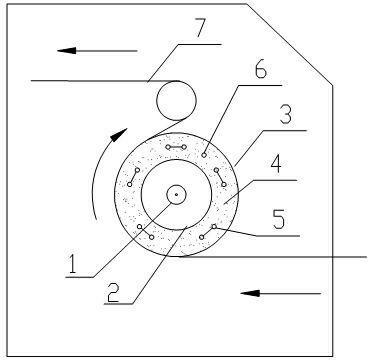

[0019] A drum type heat transfer oil heating system for a digital sizing machine, including a rolling shaft 1, an inner cylinder 2 and an outer cylinder 3 are arranged outside the rolling shaft 1 in turn, and a heat transfer oil 4 is sealed between the inner cylinder 2 and the outer cylinder 3, and the heat transfer oil 4 A heating strip 5 is provided inside.

[0020] The heat transfer oil 4 is provided with a temperature sensor 6 . The temperature of the heat transfer oil is measured by a temperature sensor, and the heating temperature is precisely controlled.

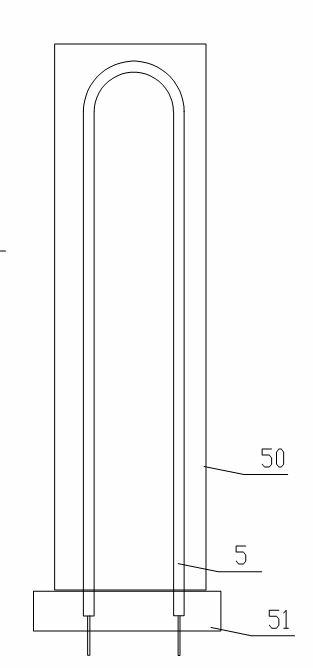

[0021] The heating strip 5 is arranged in the housing 50 , the heating strip 5 is U-shaped in the housing 50 , and the two electrodes of the heating strip 5 are led out through the end plate 51 . The casing 50 is arranged between the inner cylinder 2 and the outer cylinder 3, and the two electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com