Electric heating device and system

An electric heating device and electrode technology, applied in the coupling of optical waveguide, etc., can solve the problems of easy drift, narrow range of flame temperature adjustment, difficult to control, etc., achieve uniform and stable heating, avoid unstable and uniform, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are only used to illustrate the present invention, but can not be used to limit the scope of the present invention.

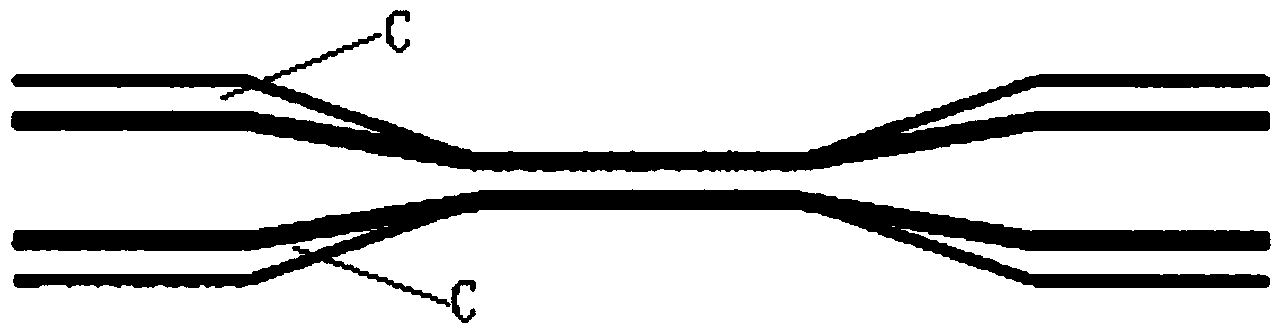

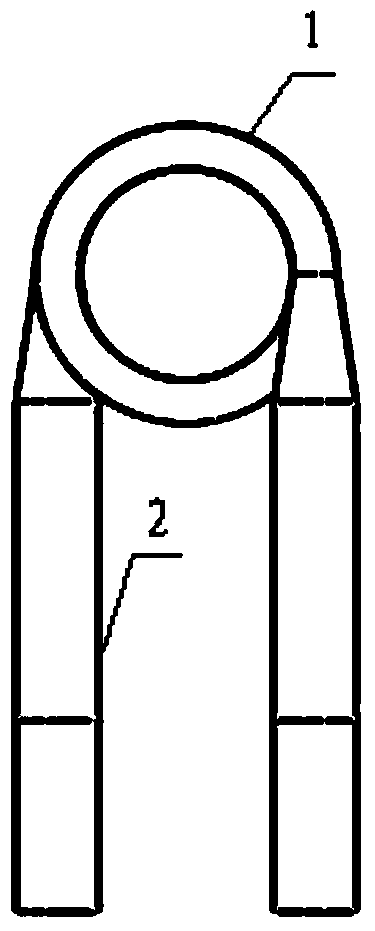

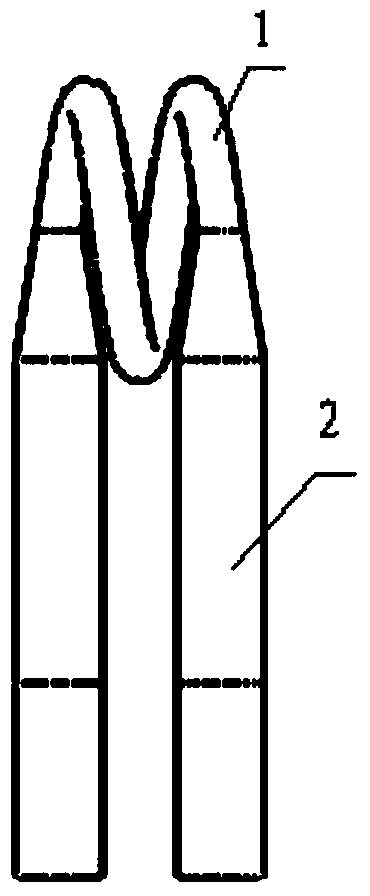

[0038] Figure 2 to Figure 8 The structure of the electric heating device of a preferred embodiment of the present invention is shown. As shown in the figure, the electric heating device of the present invention includes a heating element 1, two electrodes 2 and a ceramic shell 3, and the two electrodes 2 are connected to both ends of the heating element 1; a cavity 31 is formed inside the ceramic shell 3 to generate heat. The body 1 is placed in the cavity 31; the top of the ceramic shell 3 forms a notch 32 that runs through the thickness direction of the ceramic shell 3 and communicates with the cavity 31. The heating element 1 has a helical structure, and the position of the helical structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com