Secondary sizing device of glass fiber

A technology of glass fiber and filter device, which is applied in the direction of processing textile material equipment configuration, dumping textile material processing, liquid/gas/vapor yarn/filament processing, etc., can solve the problems of affecting quality, affecting sizing quality, increasing production costs, etc. , to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

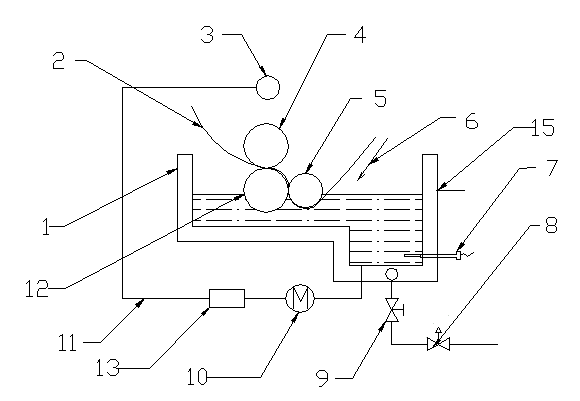

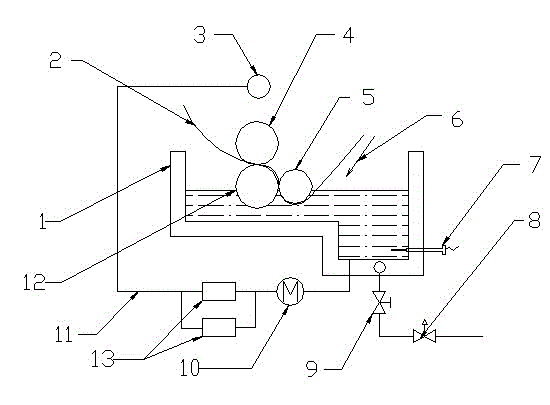

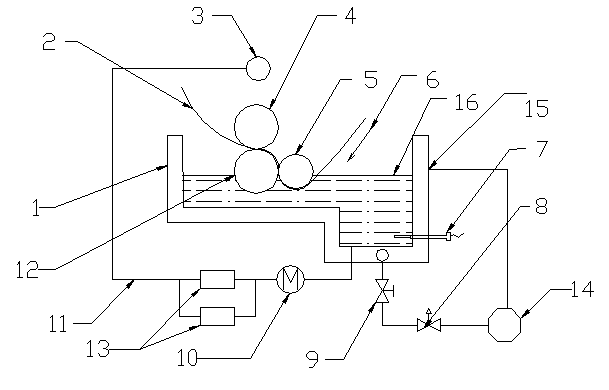

[0029] Such as figure 1 As shown, a glass fiber secondary sizing device includes a size tank, a sizing system, a size tank heating system and a filter device. The sizing system includes a sizing roller group and a sizing device. The sizing roller group is arranged in the size tank. The sizing rollers provided, wherein the first sizing roller 5 and the second sizing roller 12 are arranged side by side in the slurry 16 of the size tank, the third sizing roller 4 is arranged outside the slurry 16, and the glass fiber warp yarn 2 passes through the slurry 16 from the first sizing roller 5 and the second sizing roller 12, and then pass between the second sizing roller 12 and the third sizing roller 4, after sizing, the glass fiber warp is squeezed between the two sizing rollers to complete the second sizing The showering device includes a showering pipe 11 and a showering head 3, one end of the showering pipe 11 communicates with the slurry tank, and the other end is connected to t...

Embodiment 2

[0033] The rest are the same as in Example 1, except that the cavity is filled with steam.

Embodiment 3

[0035] The rest are the same as in Embodiment 1, the difference is that the temperature adjustment actuator is an electric heating device arranged in the cavity, the electric heating device is electrically connected to the controller, and the controller performs data processing after receiving the temperature signal and outputs the control signal Provide an electric heating device, and the electric heating device performs hot water heating treatment according to the control signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com