Preparation method of proteins and protein-based sizes for warp sizing

A warp yarn sizing and protein technology, which is applied in the field of protein and protein-based sizing preparation, and achieves the effects of excellent sizing effect, good film-forming properties and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Soy protein size sizing polyester cotton blended yarn

[0038] (1) Preparation of soybean protein slurry:

[0039] Soybean is used as the raw material of the slurry, placed in a sodium hydroxide solution with a concentration of 0.1%, and the mass percentage of protein is 0.01% to 10%. After the mixed solution is fully stirred, it is heated at a constant temperature of 90°C for 30 minutes. Adjust the pH of the slurry to 7 to 8 with 37% hydrochloric acid, remove undissolved precipitated substances by centrifugation or suction filtration, and finally prepare soybean protein slurries with three concentrations (0.5%, 1%, 1.5%).

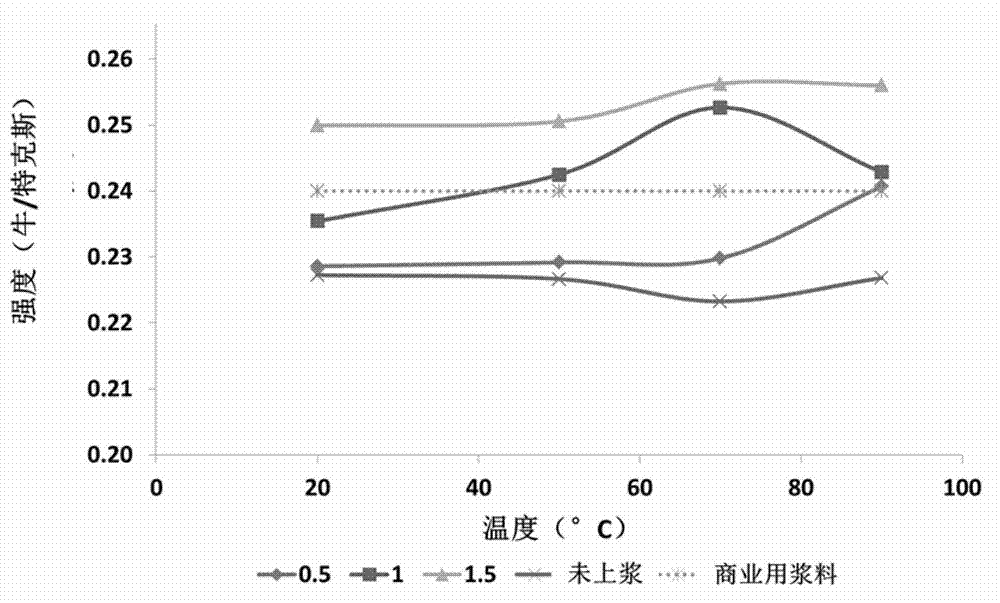

[0040] Polyester-cotton blended yarns are sized with three concentrations (0.5%, 1%, 1.5%) of soybean protein sizing at different temperatures (20°C, 50°C, 70°C, and 90°C), and commercial sizing is used The same polyester-cotton blended yarn with sizing was used as the control group. figure 1 The difference in tensile strength of sized and unsize...

Embodiment 2

[0042] Soy protein size sizing polyester yarn

[0043] Soybean protein is used as the raw material of the slurry, placed in a sodium hydroxide solution with a concentration of 0.1%, and the protein mass percentage is 0.01% to 10%. After the mixed solution is fully stirred, it is heated at a constant temperature of 90°C for 30 minutes. The pH of the slurry is adjusted to 7 to 8 with 37% hydrochloric acid, and the undissolved precipitate is removed by centrifugation or suction filtration to finally obtain soybean protein slurry.

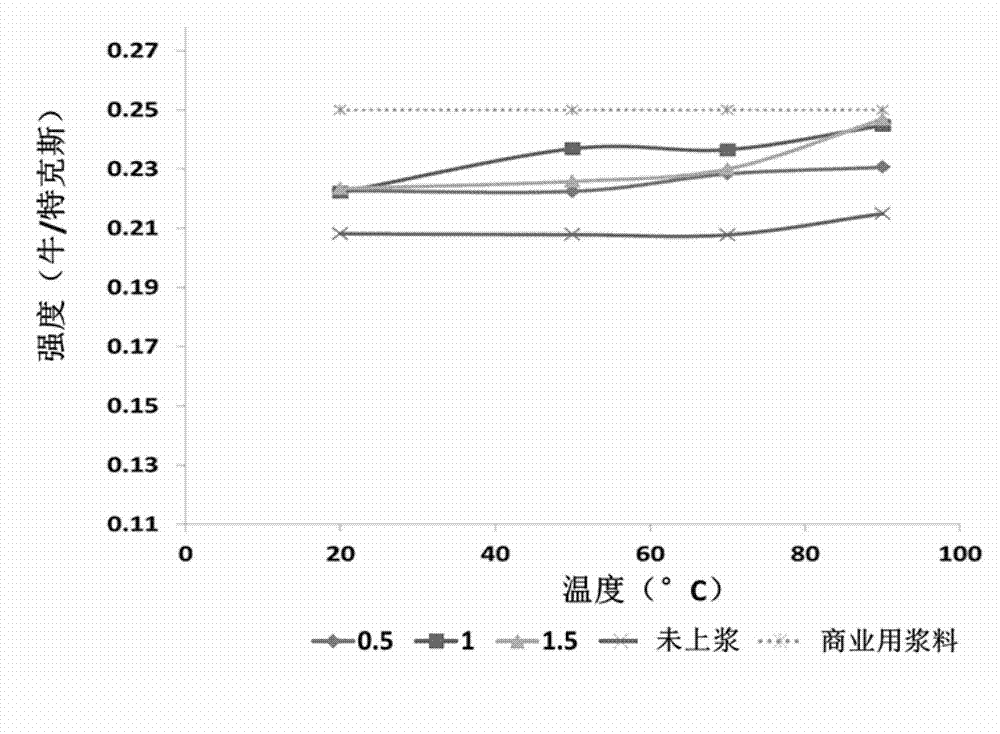

[0044] figure 2Tensile strength of polyester yarn sized with soy protein size is demonstrated. The tensile strength of sized polyester yarn was higher than that of unsized yarn, but lower than that of yarn treated with commercial size PVA.

Embodiment 3

[0046] Properties of Wheat Protein Slurry

[0047] Commercially available wheat gluten contains 80% protein and can be used for slurry preparation.

[0048] Wheat protein is used as the raw material of the slurry, placed in a sodium hydroxide solution with a concentration of 0.1%, and the protein mass percentage is 0.01% to 10%. After the mixed solution is fully stirred, it is heated at a constant temperature of 90°C for 30 minutes. The pH of the slurry is adjusted to 7 to 8 with hydrochloric acid with a concentration of 37%, and the undissolved precipitate is removed by centrifugation or suction filtration, and finally the wheat protein slurry is obtained.

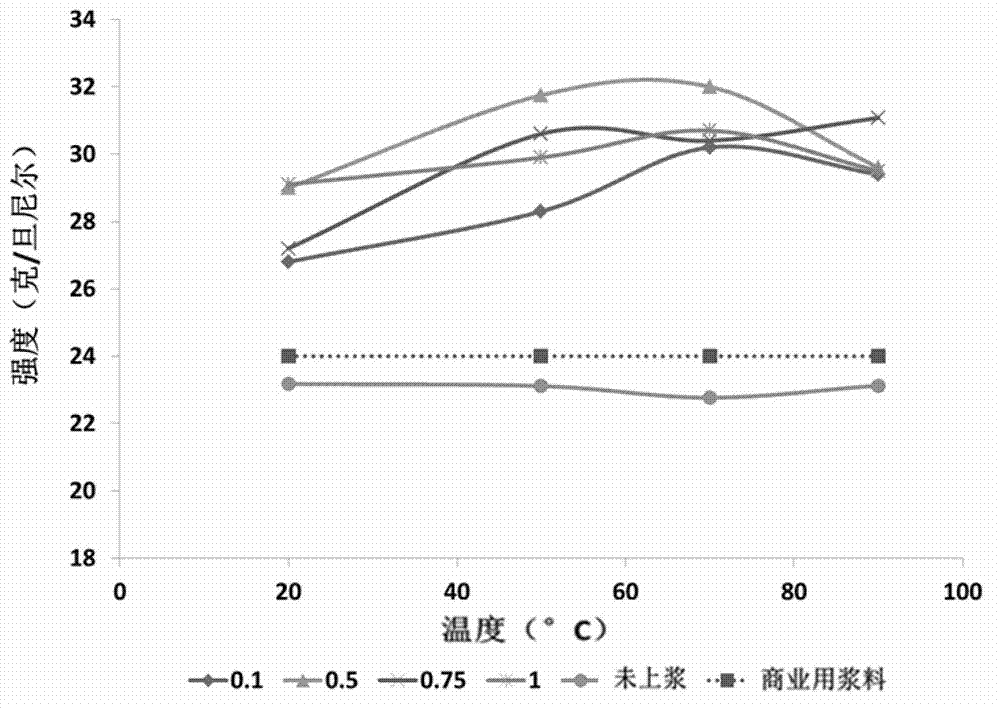

[0049] The properties of polyester-cotton blended rovings, polyester rovings, spun yarns and fabrics treated with wheat protein size are listed in Table 1. In Table 1, the stretching and abrasion resistance effects of wheat protein on polyester-cotton blended rovings and fabrics after sizing are similar to those of comme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com