Organic montmorillonite/acrylic acid size and preparation method thereof

An organic montmorillonite, acrylic technology, applied in textiles, papermaking, fiber processing and other directions, can solve the problems of equipment damage, the size is not greatly improved, etc., to improve adhesion, low cost, improve yarn strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

[0047] Preparation of organic montmorillonite: Dissolve 4g of inorganic sodium-based montmorillonite in water, heat to 80°C, and keep stirring. According to the cation exchange capacity (CEC) of montmorillonite, add 2.62g of cetyltrimethyl ammonium bromide, and keep stirring for 4h, filter, and wash the filtered modified organic montmorillonite with deionized water until no Br ions in the filtrate can be detected by AgNO3, and the obtained product is air-dried at 60°C for 24h, and ground After passing through a 70-mesh sieve, organic montmorillonite (O-MMT) is obtained.

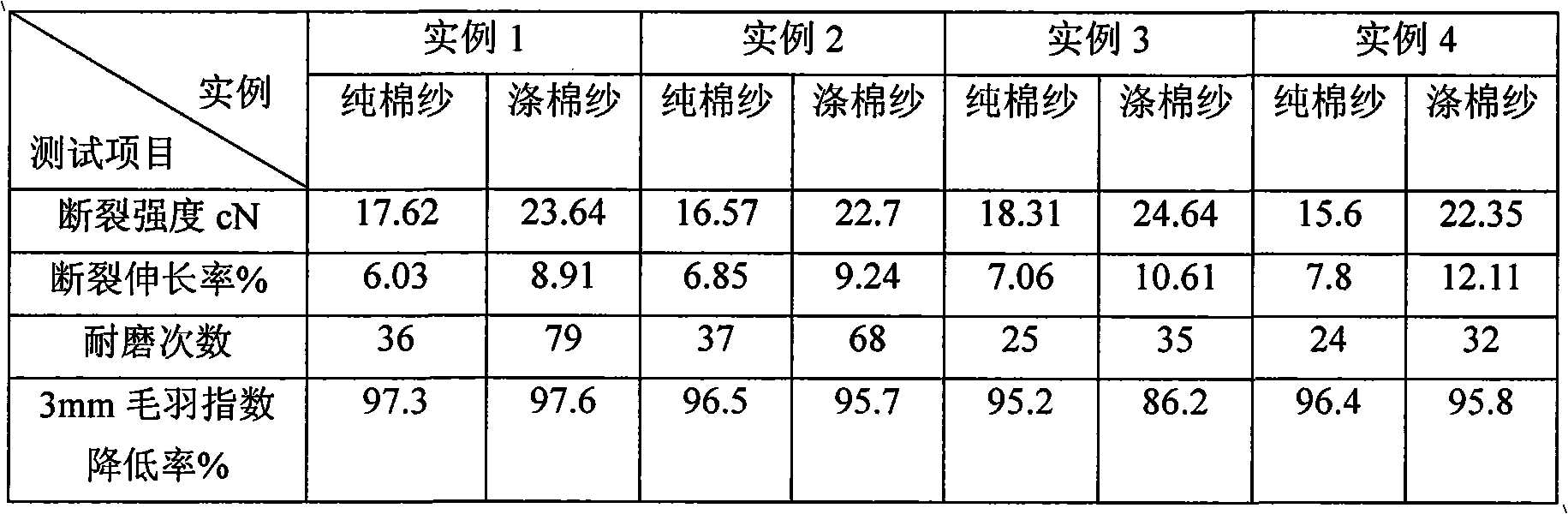

[0048] The preparation example of montmorillonite / acrylic nano-textile slurry is shown in Table 1. In order to make a certain comparison, except for the quality of the substances added during preparation, the reaction temperature, holding time, heating rate, etc. are all the same.

preparation example

[0051] Taking the synthesis reaction step of example 1 as example, other three reaction steps are all the same as example 1:

[0052] The first step: raw material pretreatment

[0053] (1) Mix 2g of organic montmorillonite, 1.45g of SDBS / OP-10 composite emulsifier, and 160g of water, and ultrasonically disperse for 30min to make it fully mixed until there is no agglomerated particle;

[0054] (2) the acrylic monomer is mixed by each quality of example 1, then add the SDBS / OP-10 composite emulsifier of 1.45g, the acrylic monomer is emulsified;

[0055] (3) Dissolve 0.74 g of persulfate in 50 g of water.

[0056] Step 2: Synthesis

[0057] (1) The solution that is dissolved with organic montmorillonite is transferred to a four-necked flask equipped with a rotor, a condenser and a thermometer, and vigorously stirred;

[0058] (2) Put the emulsified monomer into the monomer dropping device, drop 1 / 6 to 1 / 3 of the amount into the four-necked flask, then put the initiator ...

Embodiment 5

[0065] The slurry and the size film quality test of the slurry of above 4 embodiments:

[0066] Description of sample preparation and test conditions:

[0067] 1. Viscosity test

[0068] Take the slurry and dilute it into a solution with a mass fraction of 4%, and measure the viscosity of the slurry with a NDJ-79 rotary viscometer at 30°C

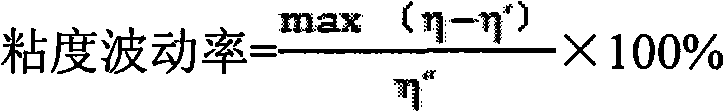

[0069] 2. Viscosity fluctuation rate

[0070] Dilute the slurry into a solution with a mass fraction of 4%, start timing from rising to 95°C, and heat at 95°C for 60min, 90min, 120min, 150min, and 180min respectively (incubating at 95°C for 3h, The comparison between the extreme difference of the viscosity measured 5 times) and the viscosity value measured at 95°C for 1h is calculated according to the following formula:

[0071]

[0072] In the formula, η″——the viscosity value of the sample measured at 95°C for 1h, mPa·s;

[0073] max(η-η')——respectively at 95°C for 60min, 90min, 120min, 150min, and 180min, and the extreme difference...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com