Plastic-emulated printing paper and its manufacturing technique

A production process and printing paper technology, applied in the field of papermaking, can solve the problems of reduced printing aesthetics, poor barrier performance, and reduced food shelf life, and achieve the effects of prolonging food freshness, good printability, and maintaining paper surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

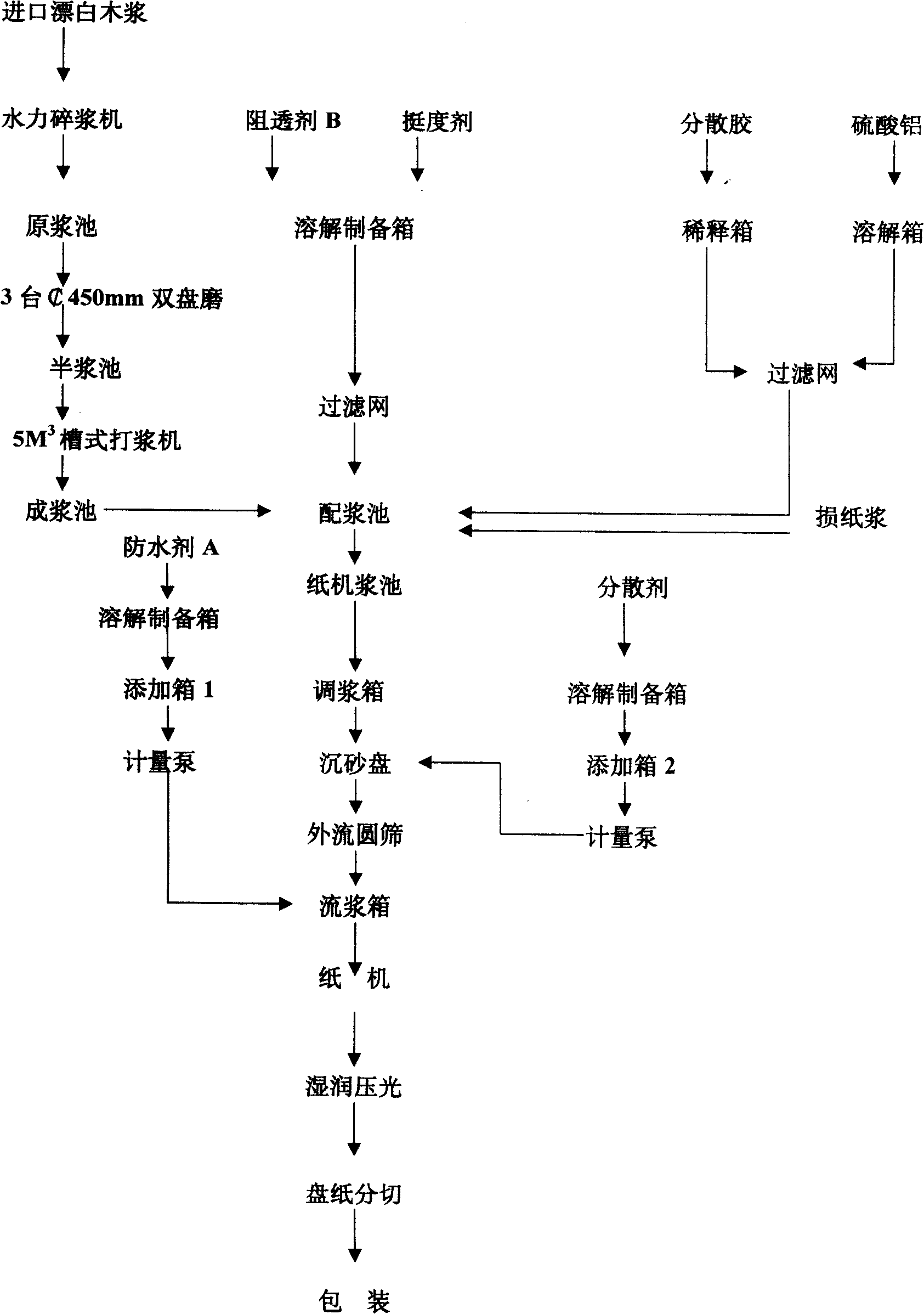

[0016] Accompanying drawing has provided the concrete implementation process flowchart of the present invention:

[0017] 1) Raw material ratio: 100% bleached pulp, add water

[0018] 2) Beating: ¢450mm double disc mill 4 sets

[0019] 5M 3 4 trough beaters

[0020] Beating concentration 4.6~5.0%

[0021] Slurry percussion degree 86~88°SR wet weight 6.0~7.0g

[0022] 3) Mixing slurry: concentration 2.20~2.30%

[0023] Dispersion gel 1.5% Aluminum sulfate 5.0%

[0024] 4) Paper machine: speed 80-82 m / min

[0025] Quantitative 22.0±1.0g / m 2

[0026] Internet concentration 0.40~0.45%

[0027] Amplitude 1 stage 4mm, 2 stages 8mm Vibration frequency 200~220 times / min

[0028] Squeeze pressure 1 Press 18~20kgf / cm 2 2 22~24kgf / cm 2

[0029] Base paper moisture 5-8%

[0030] 5. Wet calendering: wet moisture 16-18%

[0031] Calendering pressure 15~18kgf / cm 2

[0032] 6. Paper: Moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com