Agarwood calligraphy and painting paper and preparation method thereof

A technology of calligraphy and painting paper and agarwood, which is applied in the field of papermaking, can solve the problems of poor ink absorption and dimensional stability, low bulk, and low fracture length, etc., and achieve the effects of high ink moistening effect, white paper quality, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

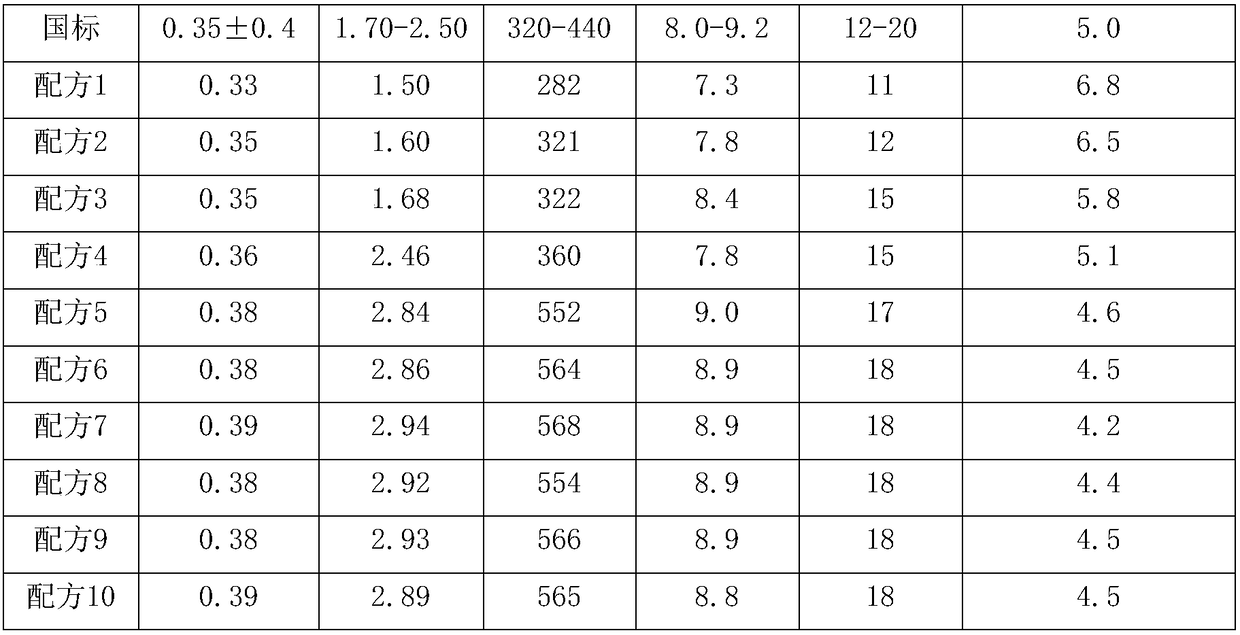

Examples

Embodiment 1

[0048] Example 1: Preparation of agarwood calligraphy and painting paper

[0049] Painting and calligraphy paper materials: Broussonetia papyrifera bark 1kg, cactus juice 100g, agarwood powder 10g, taro powder 10g, vanilla juice 50g, aloe juice 50g, potassium carbonate 100g, lime 100g;

[0050] Preparation:

[0051] (1) Wash the paper mulberry bark with clean water to remove the sludge on the bark, put it into the soaking tank, add 6 times the amount of 5% sodium hydroxide solution, and soak for 2 days.

[0052] (2) Wash the paper mulberry bark soaked in step (1) with clean water, put it in a fumigation bucket, steam it with steam for 10 hours, and put it in.

[0053] (3) Put the paper mulberry bark steamed by the steam in step (2) into the soaking tank, add 4 times the amount of water, add lime, stir evenly, and soak for 6 days.

[0054] (4) Take the Broussonetia papyrifera bark soaked in step (3), clean it with water, crush it, put it in a stone pot and mash it into a muddy surface, mi...

Embodiment 2

[0056] Example 2: Preparation of agarwood calligraphy and painting paper

[0057] Painting and calligraphy paper materials: Broussonetia papyrifera bark 2kg, cactus juice 200g, agarwood powder 50g, taro powder 40g, vanilla juice 50g, aloe juice 50g, potassium carbonate 150g, lime 200g;

[0058] Preparation:

[0059] (1) Wash the paper mulberry bark with clean water to remove the sludge on the bark, put it into the soaking tank, add 6 times the amount of 5% sodium hydroxide solution, and soak for 2 days.

[0060] (2) Wash the paper mulberry bark soaked in step (1) with clean water, put it in a fumigation bucket, steam it with steam for 10 hours, and put it in.

[0061] (3) Put the paper mulberry bark steamed by the steam in step (2) into the soaking tank, add 4 times the amount of water, add lime, stir evenly, and soak for 6 days.

[0062] (4) Take the Broussonetia papyrifera bark soaked in step (3), clean it with water, crush it, put it in a stone pot and mash it into a muddy surface, mi...

Embodiment 3

[0064] Example 3: Preparation of agarwood calligraphy and painting paper

[0065] Painting and calligraphy paper materials: Broussonetia papyrifera bark 2.5kg, cactus juice 250g, agarwood powder 80g, taro powder 50g, vanilla juice 180g, aloe juice 170g, potassium carbonate 200g, lime 250g;

[0066] Preparation:

[0067] (1) Wash the paper mulberry bark with clean water to remove the sludge on the bark, put it into the soaking tank, add 7 times the amount of 5% sodium hydroxide solution, and soak for 4 days.

[0068] (2) Wash the paper mulberry bark soaked in step (1) with clear water, put it in a fumigation bucket, steam it with steam for 14 hours, and put it in.

[0069] (3) Put the paper mulberry bark steamed by the steam in step (2) into the soaking tank, add 5 times the amount of water, add lime, stir evenly, and soak for 7 days.

[0070] (4) Take the Broussonetia papyrifera bark soaked in step (3), clean it with water, crush it, put it in a stone pot, smash it into a muddy surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com