A kind of method that takes bamboo as raw material to prepare painting and calligraphy paper

A technology for calligraphy and painting paper and raw materials, applied in pulp beating method, pulp beating/refining method, special paper, etc., can solve the problem of poor viscose filtration performance and bamboo pulp sales difficulties that affect the economic benefits and sustainable development of enterprises and other problems, to achieve the effect of environmental protection, high ink moistening effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

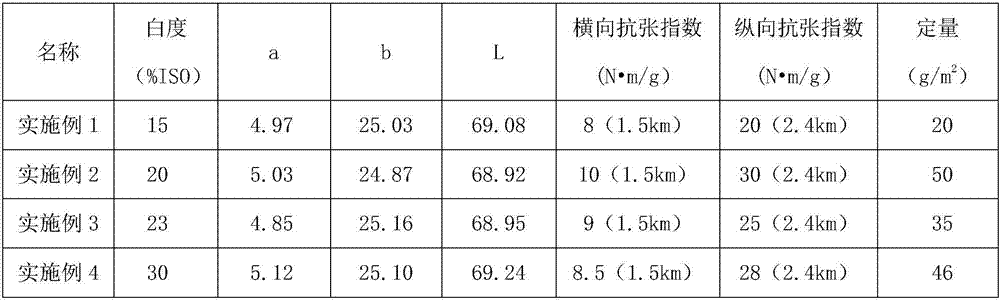

Examples

Embodiment 1

[0022] Embodiment 1: a kind of method that takes bamboo as raw material to prepare painting and calligraphy paper, it may further comprise the steps:

[0023] S1. Washing: cut the moso bamboo into slices, add salt water with a mass percentage concentration of 20-40% for washing, and remove bamboo foam and long bamboo slices by passing the bamboo slices through a swinging sieve;

[0024] S2. Pre-soaking: Add lye to the bamboo chips after washing to soak with steam heating, and the lye is a mixed solution of 15% sodium hydroxide and 10% potassium hydroxide at a concentration of 15% by mass; The temperature is 50°C, and the soaking time is 50 minutes;

[0025] S3. Cooking: continue heating the lye to 120°C and keep it warm for 30 minutes to obtain softened bamboo chips;

[0026] S4. Rubbing and refining: Add water to the softened bamboo chips and then carry out mechanical refining and silk rubbing, until the length of the gained fiber is 20-mm; 3%;

[0027] S5. Washing: The fi...

Embodiment 2

[0030] Embodiment 2: a kind of method that takes bamboo as raw material to prepare painting and calligraphy paper, it may further comprise the steps:

[0031] S1. Washing: cut yellow bamboo and Ci bamboo into slices, add salt water with a mass percentage concentration of 40% for washing, and remove bamboo foam and long bamboo slices by passing the bamboo slices through a swinging sieve;

[0032] S2. Pre-soaking: Add lye to the bamboo chips after washing to soak with steam heating, the lye is a mixed solution of 30% sodium hydroxide and 20% potassium hydroxide at a concentration of 30% by mass; The temperature is 80°C, and the soaking time is 80 minutes;

[0033] S3. Cooking: continue heating the lye to 150°C and keep it warm for 50 minutes to obtain softened bamboo chips;

[0034] S4. Rubbing and refining: add water to the bamboo chips after softening and carry out mechanical refining and silk rubbing, until the length of the gained fiber is 70mm; the consumption of the water...

Embodiment 3

[0038] Embodiment 3: a kind of method that takes bamboo as raw material to prepare painting and calligraphy paper, it may further comprise the steps:

[0039] S1. Washing: Cut Cizhu, Shuizhu, Bamboo and Zephyr bamboo into slices, add salt water with a mass percentage concentration of 28% for washing, and remove bamboo foam and long bamboo slices by passing the bamboo slices through a swinging sieve;

[0040] S2. Pre-soaking: Add lye to the bamboo chips after washing to soak with steam heating, and the lye is a mixed solution of 20% sodium hydroxide and 14% potassium hydroxide at a concentration of 20% by mass; The temperature is 62°C, and the soaking time is 64 minutes;

[0041] S3. Cooking: continue heating the lye to 135°C and keep it warm for 38 minutes to obtain softened bamboo chips;

[0042] S4. Rubbing and refining: add water to the bamboo chips after softening and carry out mechanical refining and silk rubbing, until the length of the gained fiber is 45mm; the consump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com