An environmentally friendly degradable high-definition digital printing water transfer paper and its preparation method

A technology of water transfer paper and digital printing, applied in the field of environmentally friendly and degradable high-definition digital printing water transfer paper and its preparation, can solve the problems of low smoothness and gloss, unsatisfactory printing effect, complicated production process, etc. Good printing effect, bright color and good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

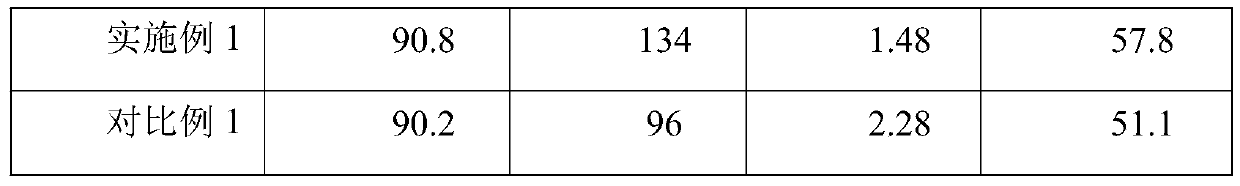

Embodiment 1

[0030] Example 1 Preparation of environmentally friendly degradable high-definition digital printing water transfer paper

[0031] Primer coating preparation: apply 70 parts of GCC (ground calcium carbonate), 0.3 parts of sodium polycarboxylate dispersant, disperser at low speed 1500r / min, then add 30 parts of china clay, increase the speed to 3000 rpm, and disperse for 20 minutes. Reduce the dispersion speed, slowly add 0.2 parts of CMC (sodium carboxymethyl cellulose), and then disperse at high speed for 20 minutes, reduce the dispersion speed, add 25 parts of acrylic latex latex, disperse for 10 minutes, add 0.6 parts of lubricant, 1 part of water-resistant agent to disperse After 10 minutes, add sodium hydroxide to adjust the pH value to 8.5, disperse at a low speed for 10 minutes, and stop the machine.

[0032] Surface coating preparation: use a powder kneader to knead and mix 10 parts of corn starch and 10 parts of wood-plastic potato starch until uniform; add 65.5 parts...

Embodiment 2

[0040] Example 2 Preparation of environmentally friendly degradable high-definition digital printing water transfer paper

[0041] Primer coating preparation: apply 80 parts of GCC, 0.3 parts of sodium polycarboxylate dispersant, disperser at a low speed of 2000r / min, then add 20 parts of China clay, increase the speed to 5000 rpm, and disperse for 20 minutes. Reduce the dispersion speed, slowly add 0.4 parts of CMC, and then disperse at high speed for 20 minutes, reduce the dispersion speed, add 40 parts of acrylic latex latex, disperse for 10 minutes, add 1.2 parts of lubricant, 1.5 parts of water repellent agent, disperse for 10 minutes, add sodium hydroxide to adjust the pH When the value reaches 8.7, add fungicide, disperse at low speed for 10 minutes, and stop the machine.

[0042] Surface coating preparation: use a powder kneader to knead and mix 15 parts of corn starch and 20 parts of wood-plastic potato starch until uniform; add 44 parts of water to the mixed starch, ...

Embodiment 3

[0049] Example 3 Preparation of environmentally friendly degradable high-definition digital printing water transfer paper

[0050] Primer coating preparation: Coating 75 parts of GCC, 0.4 parts of sodium polycarboxylate dispersant, dispersing machine at a low speed of 1800r / min, then adding 25 parts of china clay, increasing the speed to 2800 rpm, and dispersing for 20 minutes. Reduce the dispersion speed, slowly add 0.3 parts of CMC, and then disperse at high speed for 20 minutes, reduce the dispersion speed, add 30 parts of acrylic latex latex, disperse for 10 minutes, add 1 part of lubricant, 1.2 parts of water repellent agent, disperse for 10 minutes, add sodium hydroxide to adjust the pH When the value reaches 8.6, add fungicide, disperse at low speed for 10 minutes, and stop the machine.

[0051] Surface coating preparation: use a powder kneader to knead and mix 12 parts of corn starch and 15 parts of wood-plastic potato starch until uniform; add 55.3 parts of water to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com