Glueing method for papermaking process

A neutral glue and pulp technology, applied in the field of rosin glue, can solve problems such as difficulty in neutral sizing, difficulty in stabilizing sizing effect, etc., and achieve the effects of eliminating interference, enhancing practical application value, and optimizing sizing reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

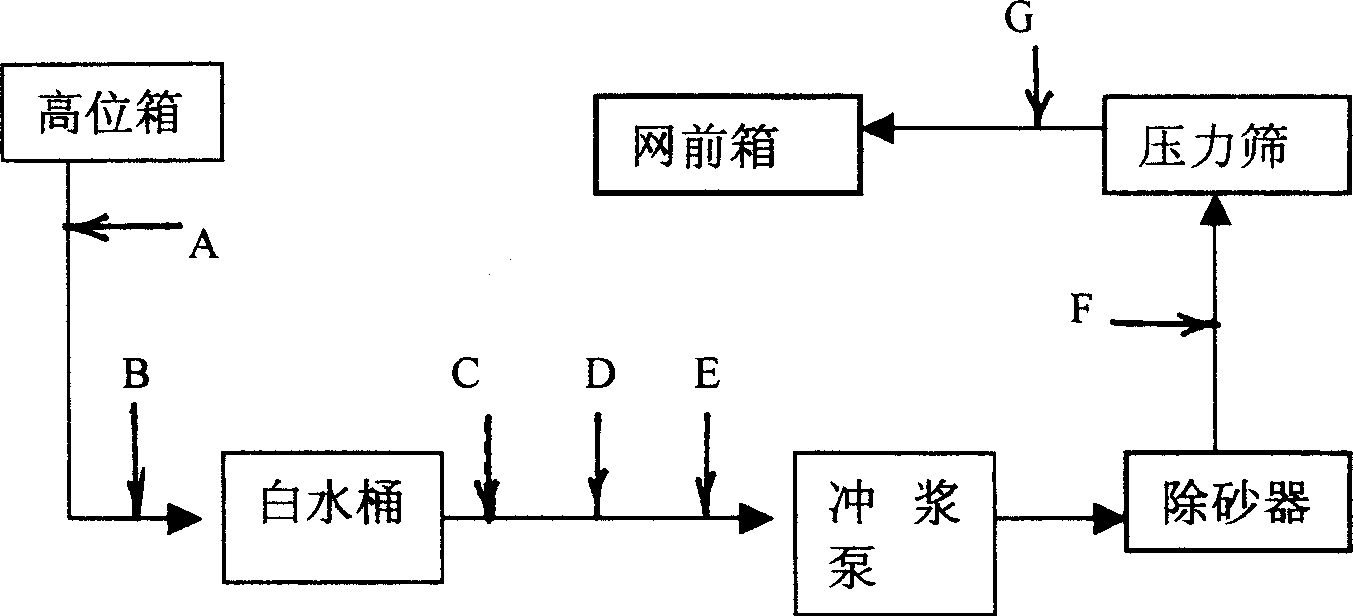

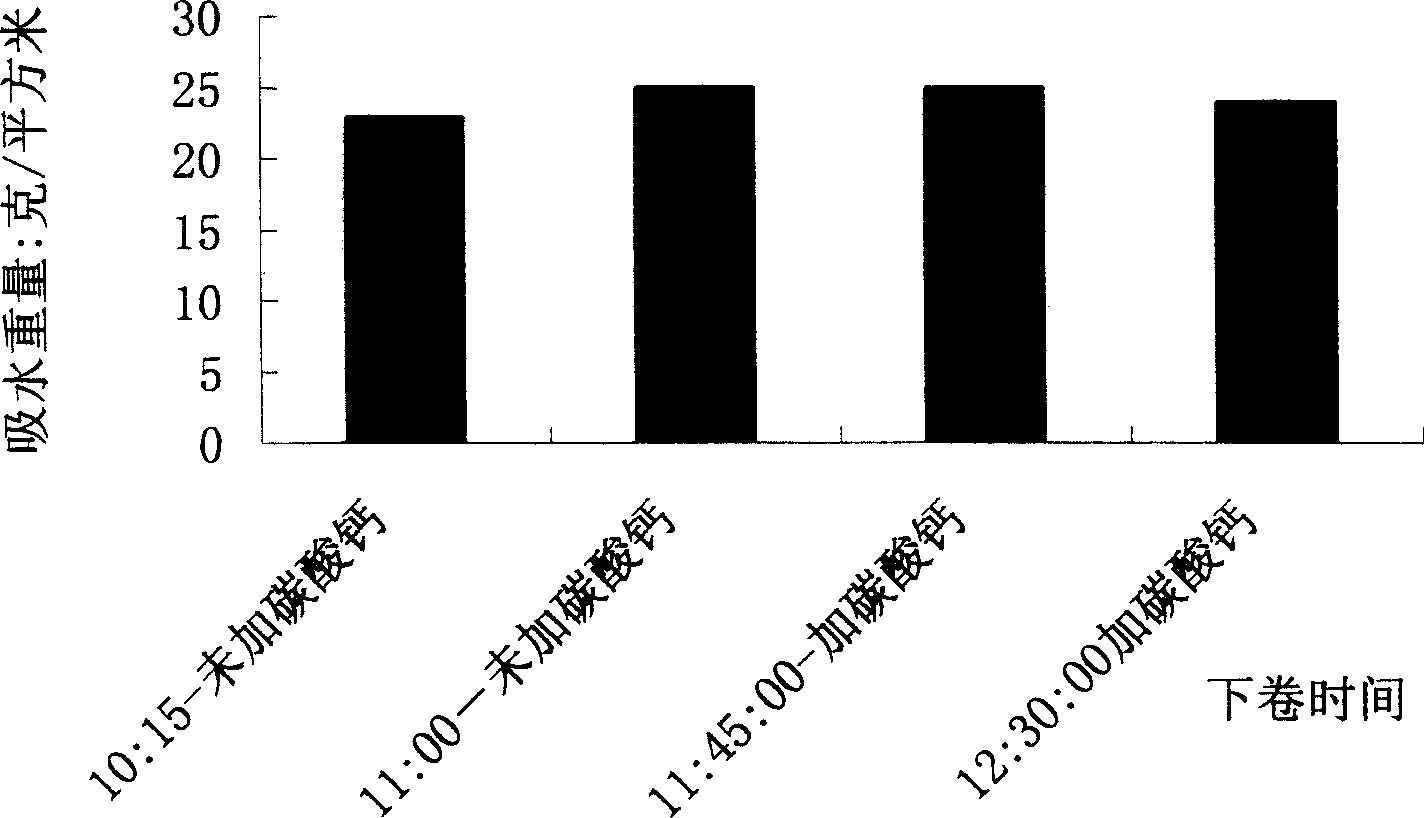

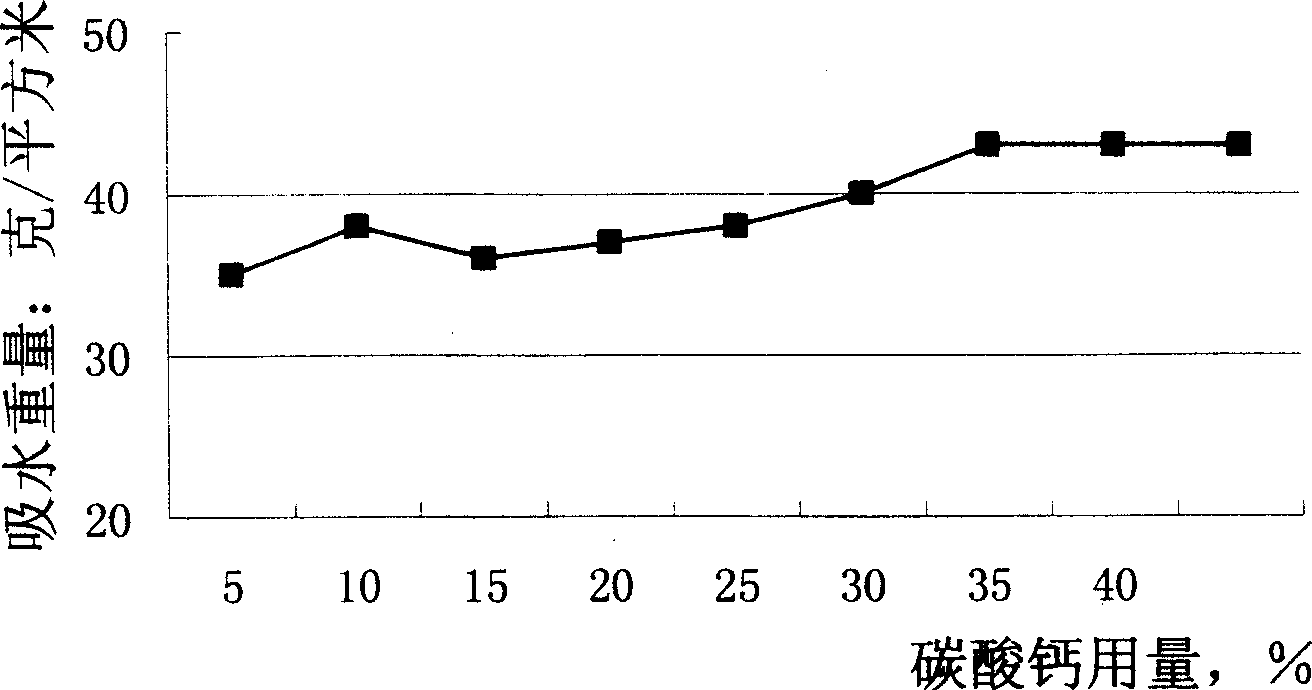

[0047] Example 1: A quaternary system composed of rosin neutral glue, aluminum sulfate, polyethyleneimine and cationic polyacrylamide is used for the neutral sizing of the coated white board paper surface pulp of the whole wood pulp vermicelli, and the vermicelli quantitative is 28g / m. . Based on 1000kg dry pulp, the dosages are: rosin neutral glue 5kg: aluminum sulfate 10kg; polyethyleneimine 2kg: cationic polyacrylamide 0.3kg. Adding points are: rosin neutral gum is added at A; polyethyleneimine is added at D; aluminum sulfate is added at B; cationic polyacrylamide is added at F; neutral papermaking CaCO 3 The filler solution is added continuously at E (CaCO 3 The dosage is 10%, calculated by weight of solids on absolute dry pulp).

Embodiment 2

[0048] Example 2: A quaternary system composed of rosin neutral glue, aluminum sulfate, cationic polyquaternary amine and polyaminoamide is used for the surface pulp of coated white board paper for the mixed pulp liner of 30% wood pulp and 70% waste paper pulp Neutral sizing, based on 1000kg of dry pulp, the dosage is: rosin neutral size 10kg: aluminum sulfate 20kg: cationic polyquaternary amine 5kg: polyaminoamide 8kg. Adding points are: rosin neutral gum is added at B; aluminum sulfate is added at C; cationic polyquaternary ammonium is added at D; polyaminoamide is added at G; neutral papermaking CaCO is added 3 The filler solution is added continuously at E (CaCO3 The dosage is 10%, calculated by weight of solids on absolute dry pulp).

Embodiment 3

[0049] Example 3: A quaternary system composed of rosin neutral glue, aluminum sulfate, polyamide polyamine epichlorohydrin, and anionic polyacrylamide is used for neutral sizing of coated white board paper with 100% waste paper pulp liner , based on 1000kg dry pulp, the dosages are: rosin neutral glue 9kg; aluminum sulfate 36kg; polyamide polyamine epichlorohydrin 6kg and anionic polyacrylamide 7kg. Adding points are: rosin neutral gum is added at C; aluminum sulfate is added at B; polyamide polyamine epichlorohydrin is added at D; anionic polyacrylamide is added at F; neutral papermaking CaCO 3 The filler solution was added continuously at E(CaCO 3 The dosage is 8%, calculated by weight of solids on absolute dry pulp).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com