Preparation method of high air permeability and water absorption inning paper for sanitary products

A hygienic product and high-permeability technology, applied in pulp beating/refining methods, textiles and papermaking, pure paper, etc., can solve the problems of increasing energy consumption, reducing paper air permeability, sticking cylinders, etc. Pulp degree, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

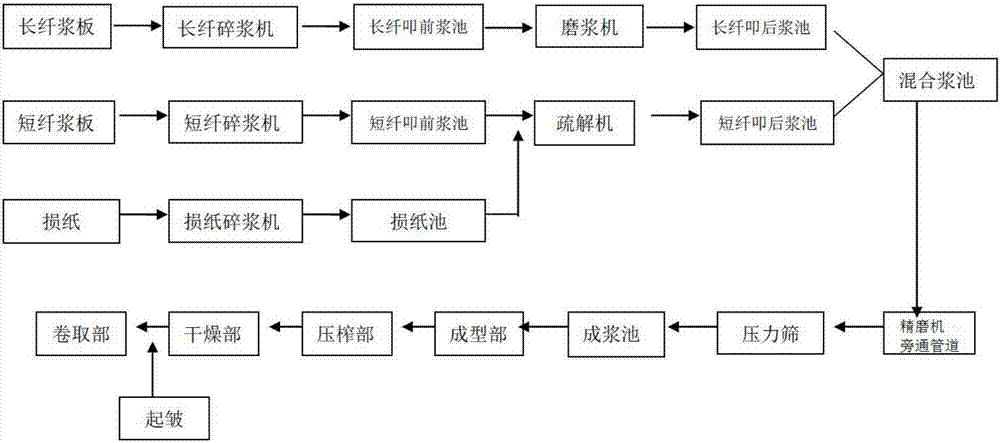

[0026] A preparation method of high air permeability absorbent lining paper for sanitary products, see the process flow chart figure 1 , The method includes the following steps:

[0027] (1) Put 7 packs of softwood pulp board (230 kg per pack air-dried) into the long-fiber pulper, a total of 1610 kg, the total volume after filling with water is about 20 cubic meters, the concentration is about 8wt%, and 10 Minutes later, it is diluted with concentrated water to a concentration of 6wt% and then pumped into the long-fiber tapping fore pulp tank.

[0028] (2) Put 7 packs of hardwood pulp into the short fiber pulper (each bag is air-dried and weigh 245 kg), a total of 1715 kg, add water to a concentration of about 8wt%, follow the same operation method of the long fiber pulper, and crush The decomposed short fiber slurry is pumped to the pulp pool before the short fiber knock;

[0029] (3) The slurry in the slurry tank before the long-fiber tapping is adjusted to 4.8wt% by thickening wa...

Embodiment 2

[0047] A method for preparing high air permeability absorbent liner paper for sanitary products, using softwood pulp as the long-fiber raw material and hardwood pulp as the short-fiber raw material. The method includes the following steps:

[0048] (1) Put the softwood pulp board into the long-fiber pulper, fill up with water to a concentration of about 8.5wt%, disintegrate for 20 minutes, dilute it with concentrated water to a concentration of 6.5wt%, and then pump into the long fiber before tapping Slurry pool.

[0049] (2) Put the broadleaf pulp into the short fiber pulper, add water to a concentration of about 8.5wt%, follow the same operation method of the long fiber pulper, and pump the broken short fiber pulp to the short fiber tap. Fore slurry tank

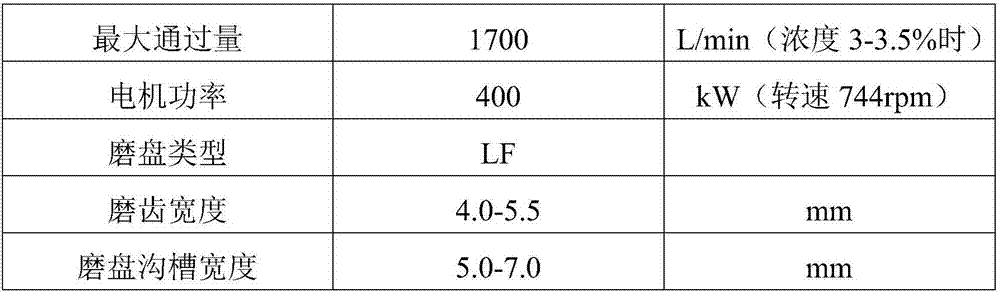

[0050] (3) The slurry in the slurry tank is adjusted to 5.3wt% by thickening water before tapping, and then enters the refiner. The speed of the refiner is 700rpm, the grinding tooth width is 4.0mm, and the grinding disc groove ...

Embodiment 3

[0057] A method for preparing high air permeability absorbent liner paper for sanitary products, using softwood pulp as the long-fiber raw material and hardwood pulp as the short-fiber raw material. The method includes the following steps:

[0058] (1) Put the softwood pulp board into the long-fiber pulper, fill up with water to a concentration of about 7.5wt%, disintegrate for 5 minutes, dilute it with concentrated water to a concentration of 5.5wt%, and then pump into the long fiber before tapping Slurry pool.

[0059] (2) Put the hardwood pulp into the short fiber pulper, add water to a concentration of about 7.5wt%, follow the same operation method of the long fiber pulper, and pump the broken short fiber pulp to the short fiber tap. Fore slurry tank

[0060] (3) The slurry in the slurry tank before the long fiber tap is adjusted to 4.5wt% by thickening water, and then enters the refiner. The speed of the refiner is 800rpm, the grinding tooth width is 5.0mm, and the grinding dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com