A method and a system for producing nanocellulose, and nanocellulose

A nano-cellulose and cellulose technology, which is applied in the post-treatment modification of cellulose pulp, fiber raw materials, fiber raw material treatment, etc., can solve problems such as high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

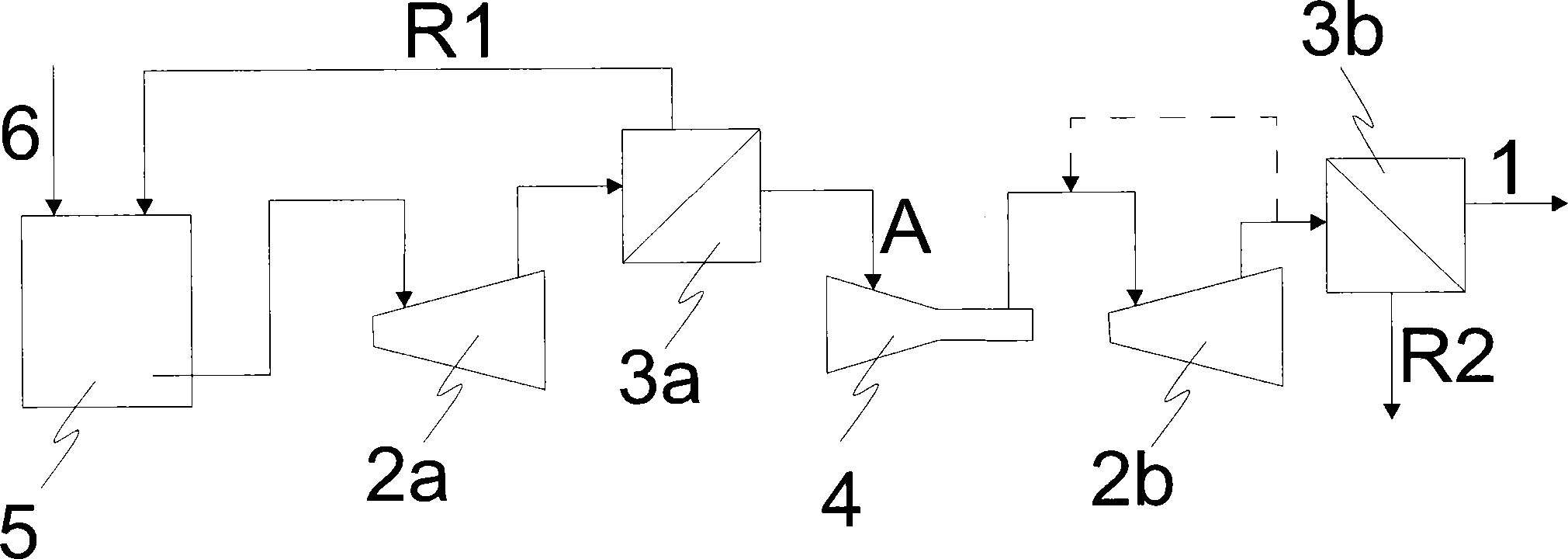

[0047] Nanocellulose is produced by refining cellulose by means of two different refiners. The first stage refiner is a low consistency refiner. The consistency of the slurry when introduced to the refiner was about 3%. The specific energy consumption (EOK) at this refiner is 100-300 MWh / h.

[0048] After the first refiner, the slurry is separated by means of a first separator. The first separator was a pressure separator with a 0.2 mm perforated frit. The concentration of the slurry fed to the separator was about 3%, and the reject material ratio of the separator was 10%. The ratio of fractions with a size smaller than 200 microns (so-called 200 fractions) in the acceptable material was 80-85%. The reject portion of the separator is conveyed back to the first refiner for refining, so that an amount of replacement unrefined cellulose is also conveyed to the first refiner, the amount substantially corresponding to The amount of slurry conveyed onwards from the first separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com