Nanometer bacterial cellulose\polyvinyl alcohol\polyethylene glycol porous composite hydrogel

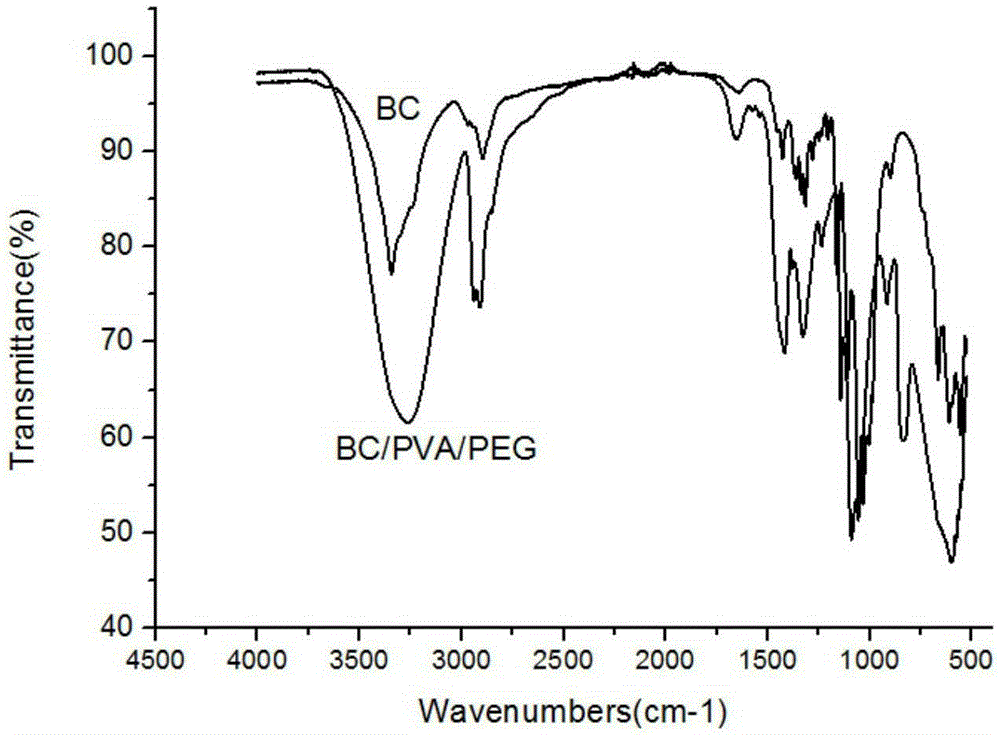

A composite hydrogel and nanobacteria technology, applied in the field of biological materials, can solve the problems of uneven cellulose fragment homogenization, uneven cellulose dispersion, poor structure controllability, etc., and achieves enhanced mechanical properties, high degree of dispersion, The effect of enhanced controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

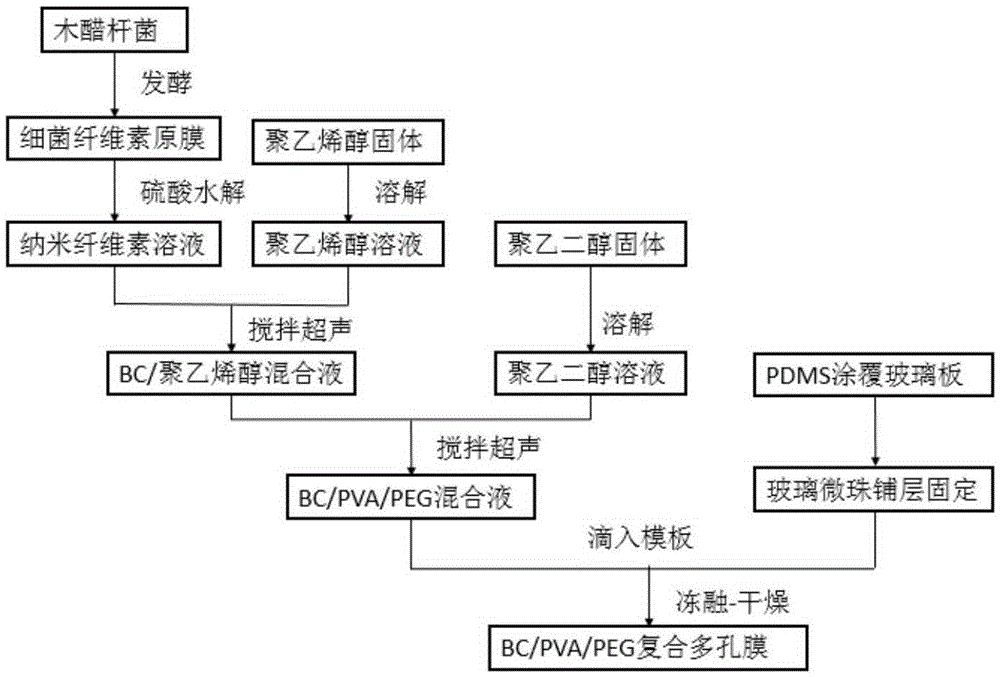

[0031] to combine figure 1 , the preparation method of nano bacterial cellulose\polyvinyl alcohol\polyethylene glycol porous composite hydrogel, the specific steps are as follows:

[0032] The first step: get the bacterial cellulose film (thickness of film 1mm~1cm) of Acetobacter xylinum dynamic fermentation, use the NaOH of mass fraction 0.1%~4% and 0.1%~4%H 2 o 2 Treat at 60-90°C for 1-5 hours, and then wash it with deionized water to obtain a pure bacterial cellulose raw material with a three-dimensional network structure;

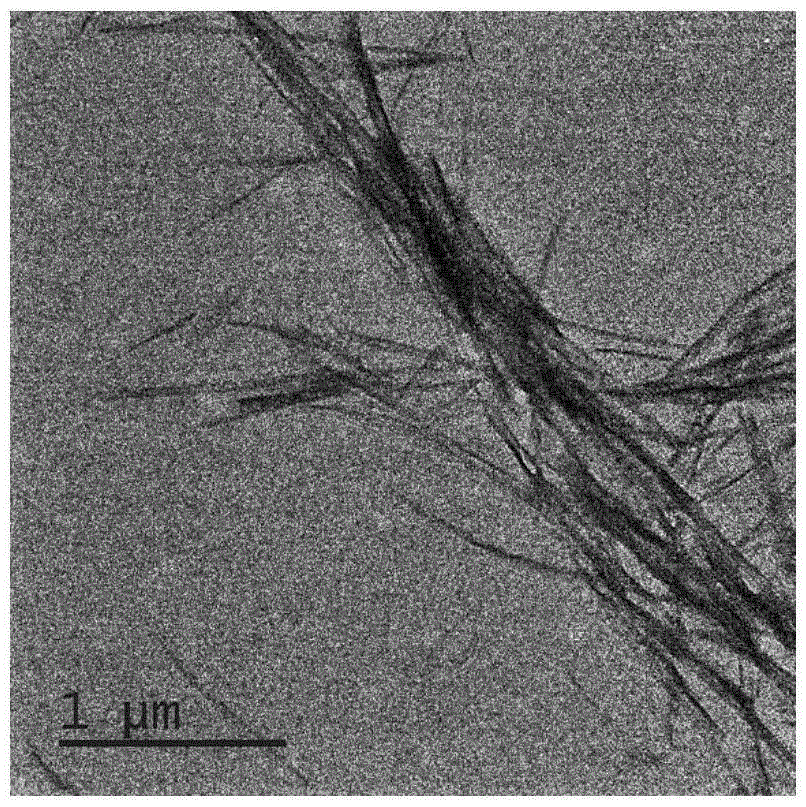

[0033] Step 2: Cut the cleaned bacterial cellulose wet film into small pieces of 1-1.5cm×1-1.5cm, squeeze out the water as much as possible and place it at a concentration of 0.01-0.1g / mL at a concentration of 50%-65%. In sulfuric acid solution, react at 45-55°C for 48 hours, collect the solution, centrifuge and wash at 8000-1000rpm, and then dialyze to pH=7;

[0034] Step 3: Prepare a PVA aqueous solution with a mass concentration of 8% to 10%, diss...

Embodiment 1

[0039]The bacterial cellulose film obtained by the static fermentation of Acetobacter xylinum was treated with 0.2% NaOH and 0.2% H 2 o 2 Treat it in a water bath at 80°C for 2 hours, take out the deionized water and rinse it; squeeze out the water as much as possible, cut it into regular 1cm×1cm small pieces with scissors, put it in 50% sulfuric acid solution at 0.01g / mL, and keep at 45°C The reaction was stirred for 48 hours, and the collected solution was centrifuged and dialyzed until completely neutral. Prepare a PVA aqueous solution with a mass concentration of 8%, prepare 4mL of a mixed solution according to the mass ratio of BC / PVA of 1 / 1, stir at 60°C for 2h, ultrasonicate for 0.5h, then add 0.3mL of a 3% PEG solution dropwise, and stir at 60°C 2h, ultrasonic 0.5h. Then, the uniformly mixed solution was added dropwise to the prepared glass microsphere template, the liquid level was about 3mm, frozen at -20°C for 6h, and then placed at room temperature for 6h, and so...

Embodiment 2

[0043] The bacterial cellulose film obtained by the static fermentation of Acetobacter xylinum was treated with 0.2% NaOH and 0.2% H 2 o 2 Treat it in a water bath at 80°C for 2 hours, take out the deionized water and rinse it; squeeze out the water as much as possible, cut it into regular 1cm×1cm small pieces with scissors, put it in 50% sulfuric acid solution at 0.05g / mL, and keep it at 50°C The reaction was stirred for 48 hours, and the collected solution was centrifuged and dialyzed until completely neutral. Prepare 8% PVA aqueous solution, prepare 4mL mixed solution according to BC / PVA mass ratio 1 / 2, stir at 70°C for 3h, ultrasonicate for 0.5h, then add 0.3mL of 5% PEG solution dropwise, stir at 70°C for 3h, Ultrasonic 0.5h. Then, the uniformly mixed solution was added dropwise to the prepared glass microsphere template, the liquid level was about 3mm, frozen at -20°C for 7h, and then placed at room temperature for 6h, and repeated 3 times. Finally, it was slightly dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com