Preparation method of surface-modified ball-milling refined plant fibers

A plant fiber and surface modification technology, which is used in grain treatment, pulping with inorganic alkali, etc., to achieve good application prospects and simple ball milling methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

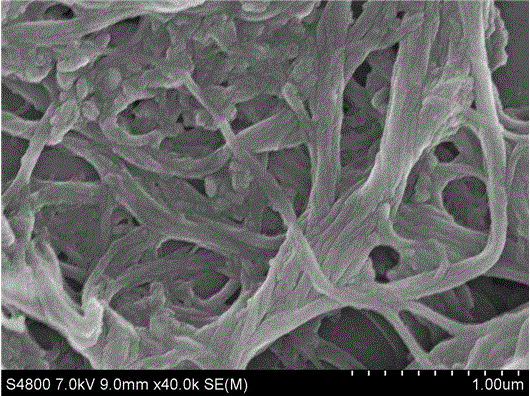

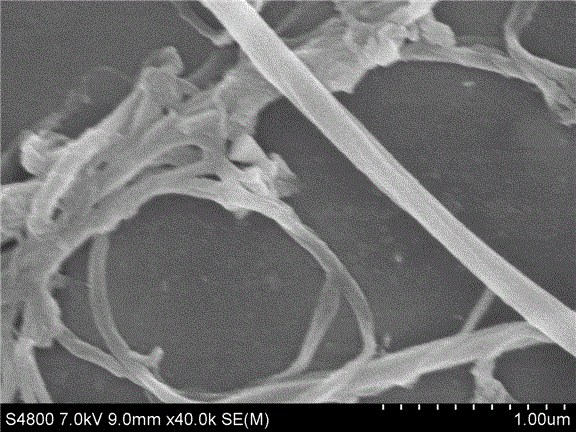

[0024] Take 100 parts by weight of dried refined kraft softwood pulp board, put it into 4900 parts by weight of water and fully wet it, beat it with a beater to 45 degrees (degree of beating °SR), and filter the obtained pulp to 4600 degrees Parts by weight of water, remaining 400 parts by weight of thick paper pulp, adding 100 parts by weight of sodium hydroxide solid in the thick paper pulp, stirring and dissolving, boiling under stirring for reflux reaction for 1 hour, to obtain a tan solid-liquid mixture, filter, use 20 % sodium hydroxide solution for 1 wash, 4 washes with water, put the filtered filter cake into 100-250 parts by weight of water to disperse, so that the pulp obtained after dispersion is 360 parts by weight, add 40 parts by weight of 30% hydrogen peroxide, Heating to 70 degrees, reacting for 1 hour under strong stirring, filtering, washing twice with water and twice with ethanol, and drying to obtain pretreated wood pulp fiber. Add the pretreated wood pulp ...

Embodiment 2

[0026] Take 100 parts by weight of sisal fiber, put it into a pulverizer and pulverize until the length is less than 1 cm, add 300 parts by weight of 20% sodium hydroxide solution, stir and boil for 3 hours to obtain a black solid-liquid mixture, filter it, and use 20% Sodium hydroxide solution washes 2 times, washes with water 4 times, filter cake is put into the water dispersion of about 100-250 weight part, makes the total weight of dispersion liquid be 360 weight part, then adds 40 weight part 30% hydrogen peroxide therein, Heating to 70 degrees under stirring and bleaching for 1 hour, filtering the product, washing with water for 3 times and ethanol for 2 times, drying to obtain pretreated sisal fiber. Take 100 parts by weight of the pretreated sisal fiber and add it to 300 parts by weight of dimethyl sulfoxide (DMSO), stir and mix evenly, pour it into a ball mill tank, replace the air in the ball mill tank with nitrogen, and then ball mill at 200rpm After 16 hours, the...

Embodiment 3

[0028] Take 100 parts by weight of rice straw, put it into a pulverizer and crush it until the length is less than 1 cm, add 500 parts by weight of 20% sodium hydroxide solution, stir and boil for 3 hours to obtain a black solid-liquid mixture, filter it, and oxidize it with 20% hydroxide The sodium solution was washed twice, and water was washed four times, and the filter cake was dispersed in 100-200 parts by weight of water, so that the total weight of the dispersion was 260 parts by weight, and then 40 parts by weight of 30% hydrogen peroxide was added thereto, heated to 70 degree, bleaching under stirring for 2 hours, filtered, washed twice with water and twice with ethanol, and dried to obtain 50-60 parts by weight of pretreated straw fiber. Take 100 parts by weight of pretreated straw fiber and add it to 300 parts by weight of dimethylformamide (DMF). After stirring and mixing evenly, pour it into a ball mill tank. Carry out 20 hours of ball milling under high temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com