Oil-proof coating white cardboard and process for producing the same

A cloth white cardboard, production process technology, applied in the field of papermaking, can solve problems such as hidden dangers, food pollution, etc., achieve high oil-proof grades, reduce production costs, and be easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

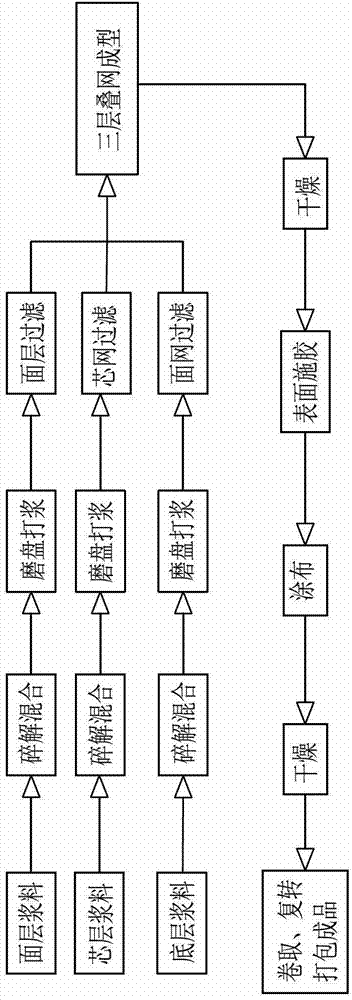

[0049] Surface layer pulp: wood pulp (weight percentage: 80% bleached hardwood kraft pulp, 20% bleached softwood kraft pulp), crushed and mixed by a pulper, refined by a disc refiner, and enter the surface of the paper machine net filter.

[0050] Core layer pulp: wood pulp (weight percentage: 70% bleached chemical thermomechanical pulp, 30% broken paper), crushed and mixed by a pulper, refined by a disc refiner, and filtered into the paper machine core net.

[0051] Bottom pulp: wood pulp (weight percentage: 75% bleached hardwood kraft pulp, 25% bleached softwood kraft pulp), crushed and mixed by a pulper, refined by a disc refiner, and enters the surface wire of the paper machine filter.

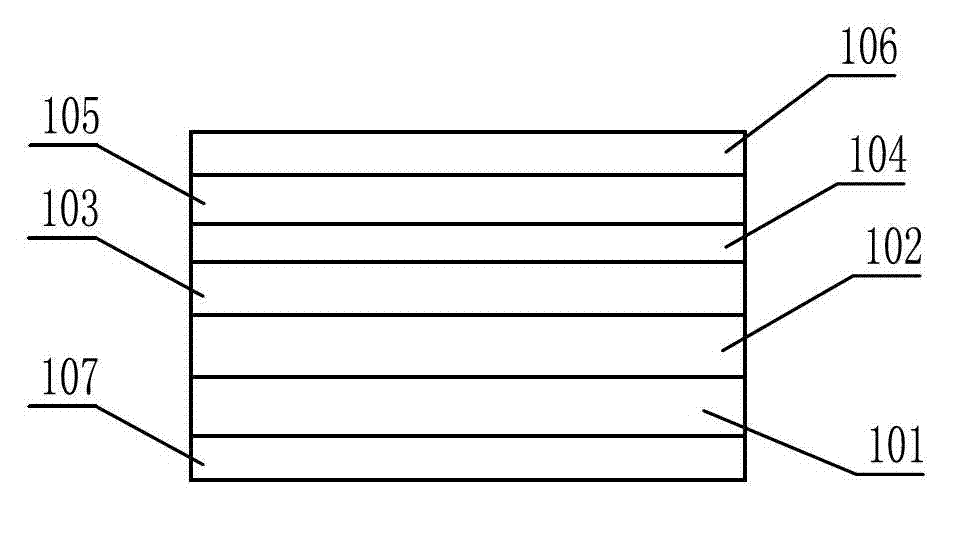

[0052] Then, a three-layer laminated wire is formed by a paper machine to produce a wet paper sheet with a surface layer 103, a core layer 102 and a bottom layer 101. The wet paper sheet is dried by a paper machine and the surface is sized to obtain a base paper.

[0053] Then, coating: ...

Embodiment 2

[0061] The production process of this embodiment is the same as that of the above-mentioned embodiment 1, the difference lies in: the slurry ratio of the surface layer slurry, the core layer slurry, and the bottom layer slurry, and the coating ratio of the back-coated oil-proof layer.

[0062] Surface pulp (percentage by weight): bleached hardwood kraft pulp 95%, bleached softwood kraft pulp 5%;

[0063] Core layer pulp (weight percent): bleached chemical thermomechanical pulp 65%, broken paper 35%;

[0064] Bottom pulp (weight percent): bleached hardwood kraft pulp 85%, bleached softwood kraft pulp 15%;

[0065] The coating ratio of the back-coated oil-proof layer is (parts by weight): 100 parts of pigment are mixed with calcium carbonate and china clay, 50 parts of calcium carbonate and china clay, 75 parts of latex, 0.6 parts of carboxymethyl cellulose, and 0.12 parts of dispersant , 1 part of anti-water agent, 1.2 parts of lubricant, 0.035 part of defoamer, 0.2 part of ca...

Embodiment 3

[0071] Surface pulp (percentage by weight): bleached hardwood kraft pulp 90%, bleached softwood kraft pulp 10%;

[0072] Core layer pulp (weight percent): bleached chemical thermomechanical pulp 75%, broken paper 25%;

[0073] Bottom pulp (weight percent): bleached hardwood kraft pulp 80%, bleached softwood kraft pulp 20%;

[0074] The paint ratio of the back-coated oil-proof layer is (parts by weight): 100 parts of pigments are all composed of china clay, that is, 100 parts of china clay, 100 parts of latex, 0.3 parts of carboxymethyl cellulose, 0.08 parts of dispersant, and 0.7 parts of water repellent part, 0.8 part of lubricant, 0.035 part of defoamer, 0.12 part of caustic soda, and 0.18 part of fungicide.

[0075] The coating amounts of the precoat layer 104, the core coat layer 105, and the top coat layer 106 were 9 g / m2, 11 g / m2, and 11 g / m2, respectively.

[0076] The produced oil-proof coated white cardboard is compared with the same quantitative ordinary white card...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com