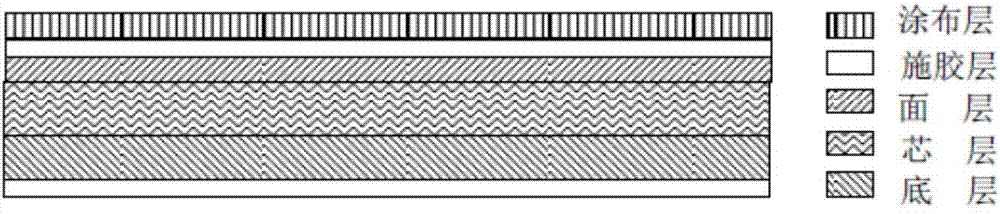

Environment-friendly low-basis-weight coated duplex board with grey back and preparation method thereof

A technology of low-weight, white board paper, applied in the field of papermaking, can solve the problems of difficult reduction of base paper price, large consumption of raw materials, high production cost, etc., and achieve the effect of improving the stiffness of the paper sheet, increasing the bonding strength, and reducing the number of production links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

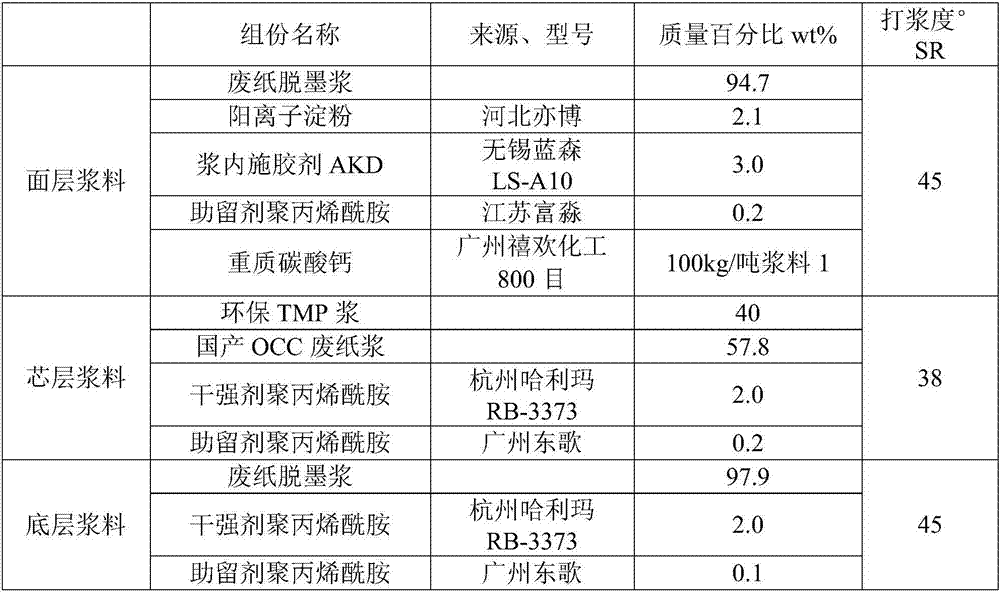

[0057] (1) Prepare each layer of slurry

[0058] Prepare surface layer slurry, core layer slurry and bottom layer slurry according to the components shown in Table 1 respectively;

[0059] (2) Base paper preparation

[0060] ①Wet paper is formed by a three-layer net paper machine

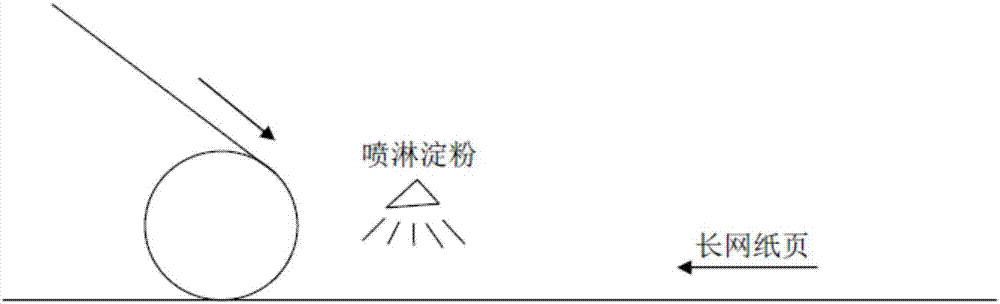

[0061] Among them, the paper dryness at the end of the wire is about 25%. The three-layer forming net is arranged horizontally in sequence, and the bottom layer, the core layer, and the surface layer are respectively copied, and the starch solution is sprayed before the bottom layer and the core layer, and the core layer and the surface layer are combined. 1.0% of the dry mass, the temperature is 65°C, and the composite dryness of the bottom layer and the core layer, the core layer and the surface layer is about 15%;

[0062] Wherein the online concentration is 0.2wt% for the surface layer, 0.6wt% for the core layer, and 0.3wt% for the bottom layer;

[0063] ② squeeze

[0064] The base paper we...

Embodiment 2

[0086] (1) Prepare each layer of slurry

[0087] Prepare surface layer, core layer and bottom layer slurry according to component shown in table 4 respectively;

[0088] (2) Base paper preparation

[0089] ①Wet paper is formed by a three-layer net paper machine

[0090] Among them, the paper dryness at the end of the wire is about 25%. The three-layer forming net is arranged horizontally in sequence, and the bottom layer, the core layer, and the surface layer are respectively copied, and the starch solution is sprayed before the bottom layer and the core layer, and the core layer and the surface layer are combined. 1.0% of the dry mass, the temperature is 65°C, and the composite dryness of the bottom layer and the core layer, the core layer and the surface layer is about 15%;

[0091] Wherein the online concentration is 0.27wt% for the surface layer, 0.88wt% for the core layer, and 0.3wt% for the bottom layer;

[0092] ② squeeze

[0093] The base paper wet paper web is se...

Embodiment 3

[0115] (1) Prepare each layer of slurry

[0116] Prepare surface layer, core layer and bottom layer slurry according to component shown in table 7 respectively;

[0117] (2) Base paper preparation

[0118] ①Wet paper is formed by a three-layer net paper machine

[0119] Among them, the paper dryness at the end of the wire is about 25%. The three-layer forming net is arranged horizontally in sequence, and the bottom layer, core layer, and surface layer are respectively copied, and the starch solution is sprayed before the bottom layer and the core layer, and the core layer and the surface layer are combined. 1.0% of the dry mass, the temperature is 65°C, and the composite dryness of the bottom layer and the core layer, the core layer and the surface layer is about 15%;

[0120] Wherein the online concentration is 0.3wt% for the surface layer, 1.17wt% for the core layer, and 0.3wt% for the bottom layer;

[0121] ② squeeze

[0122] The base paper wet paper web is sent to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com