Cleaning production technique for starch sugar

A clean production and process method technology is applied in the field of starch sugar production to achieve the effects of improving material utilization, reducing production costs and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

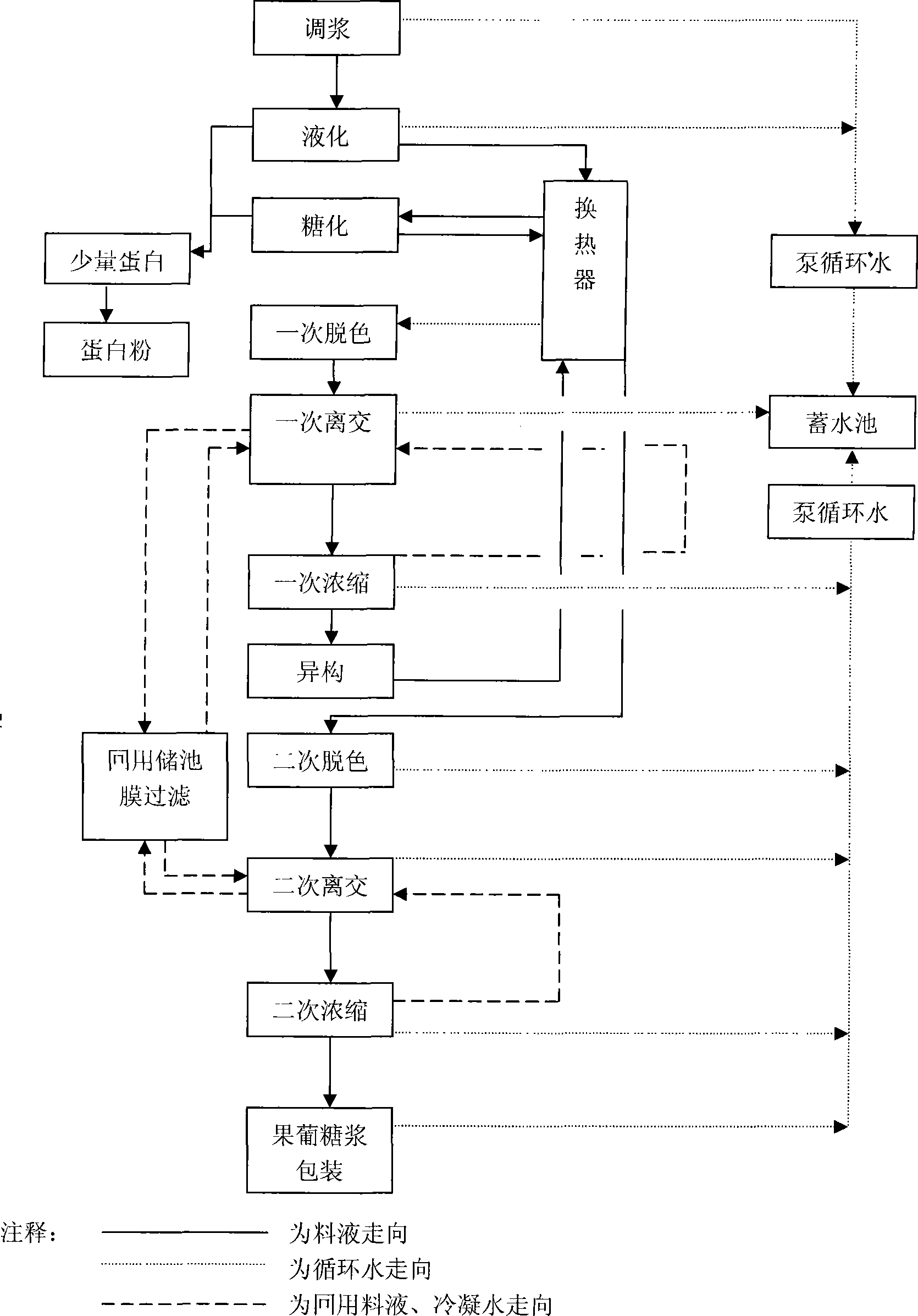

[0031] Embodiment 1, fructose syrup clean production process are as follows:

[0032] High fructose syrup includes the following production processes:

[0033] Blending, liquefaction, saccharification, primary decolorization, primary separation, primary concentration, isomerization, secondary decolorization, secondary separation, secondary concentration and finished syrup packaging;

[0034] Its clean production process is:

[0035] The process water used in the pulping process comes from the separation and cleaning water; the feed liquid after pulping, the feed liquid before decolorization and the feed liquid after liquefaction are heat-exchanged, so that the temperature of the pulping liquid, the feed liquid before primary decolorization, and the feed liquid before secondary decolorization is increased , cooling the liquefied liquid; the cleaning water in the detachment process is recycled except for pulping, and the regenerated liquid is recycled after being treated by mem...

Embodiment 2

[0041] The clean production process of isomaltooligosaccharide is as follows:

[0042] Isomaltooligosaccharide includes the following production processes:

[0043] Blending, liquefaction, saccharification, fermentation, decolorization, separation, concentration, spray drying and packaging of finished sugar powder;

[0044] Its clean production process is:

[0045]The process water used in the pulping process comes from the separation and cleaning water. The feed liquid after pulping, the feed liquid before decolorization and the feed liquid after liquefaction are heat-exchanged, so that the temperature of the pulping liquid and the feed liquid before decolorization is raised, and the temperature of the liquefied liquid is cooled. In addition to being used for slurry adjustment, the cleaning water is recycled. After the regeneration solution is treated by membrane filtration, the treatment solution is used for recycling. The regeneration residue, liquefaction solution residue...

Embodiment 3

[0050] The clean production process of dextrin is as follows:

[0051] Dextrin includes the following production processes: pulping, liquefaction, decolorization, separation, concentration, spray drying and packaging of finished syrup;

[0052] Its clean production process is:

[0053] The process water used in the pulping process comes from the separation and cleaning water. The feed liquid after pulping, the feed liquid before decolorization and the feed liquid after liquefaction are heat-exchanged, so that the temperature of the pulping liquid and the feed liquid before decolorization is raised, and the temperature of the liquefied liquid is cooled. In addition to being used for pulp adjustment, the cleaning water is recycled. After the regeneration liquid is treated by membrane filtration, the treatment liquid is used for recycling. The separation regeneration residue and the liquefaction liquid residue are used together to produce protein powder, and the concentrated cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific heat capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com