Processing method of light-color air-dried green string bean slices and salted products thereof

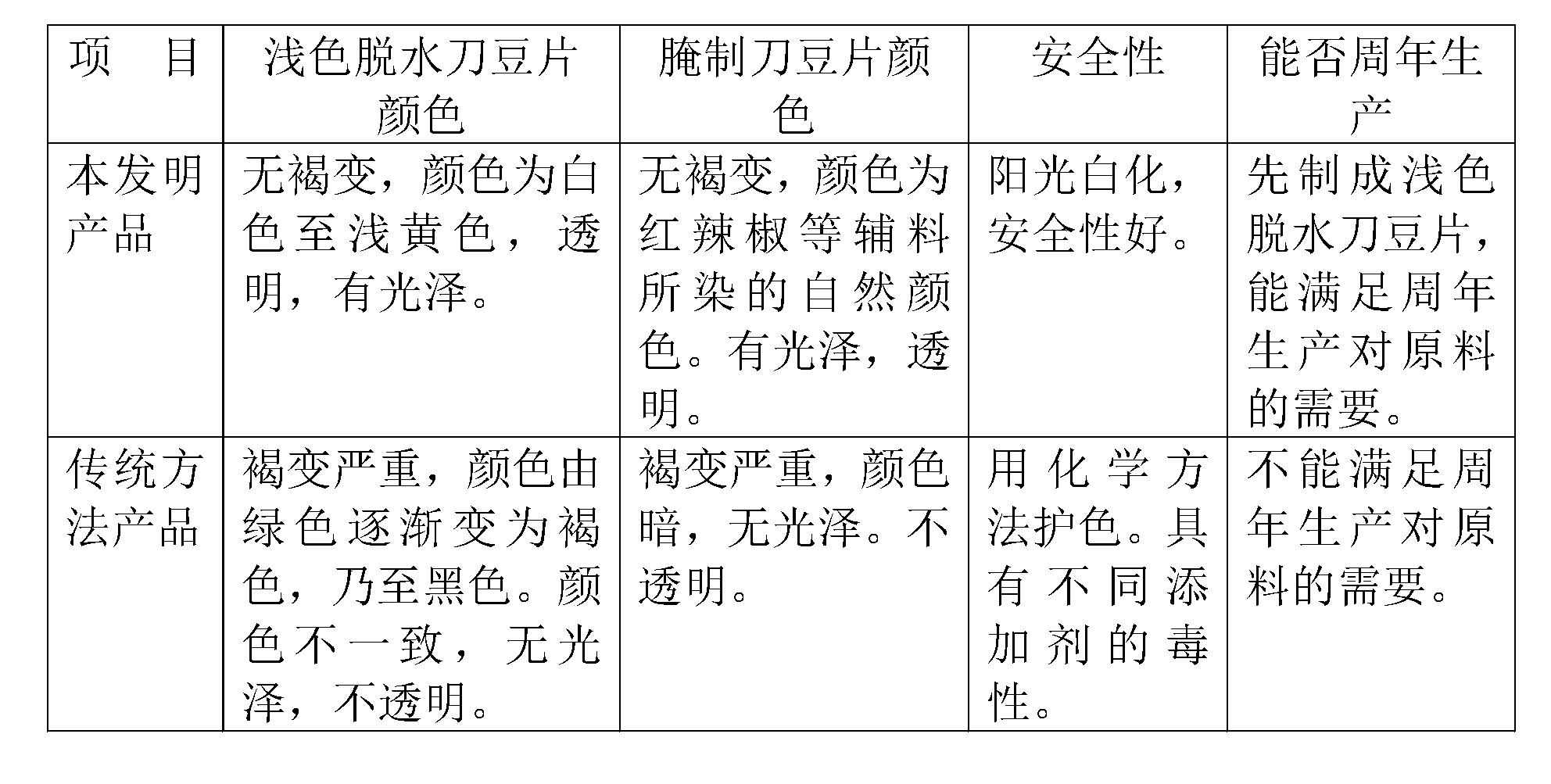

A processing method and technology of sword bean slices, which are applied in the field of processing light-colored dehydrated sword bean slices and their pickled products (pickled sword bean slices), can solve problems such as difficult market acceptance, short supply period, browning, etc. Achieve the effect of reducing production cost, dry, clean and hygienic, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Production of light-colored dehydrated beans:

[0044] Select fresh sword beans that are fully grown but the seeds have not yet expanded, remove the parts with insect eyes and disease spots, and tear off the old tendons on both sides; use a stainless steel vegetable cutter or stainless steel knife to cut the sword beans into 2-3 mm thick Thin slices; first heat the blanching water to 95°C, then immediately put the sliced sword bean slices into hot water, blanching for 1 to 2 minutes, and take them out quickly when the slices are transparent; Put the scalded sword bean slices into cooling water at room temperature to cool, rinse to 38-42°C, then take out the sword bean slices, drain the surface water, and place them in the sun to dry until white, and dry to constant weight. During the drying process, the sword bean slices should be turned frequently to make them white and dry evenly. The sun-dried sword bean slices are placed in a cool and dry environment and cooled t...

Embodiment 2

[0049] Production of light-colored dehydrated beans:

[0050] From the freshly harvested sword beans, select the fresh ones that have grown fully but the seeds have not yet expanded, remove the parts with insect eyes and disease spots, and tear off the old tendons on both sides; use a stainless steel vegetable cutter or stainless steel knife to cut the knife Cut the beans into 2-3 mm thick slices; rinse the cut beans with clean water, drain the surface moisture, and then place them in a solar drying facility (in this example, a sandwich plastic film is used as an example for illustration) Carry out blanching, the method is as follows: choose a sunny, dry, hygienic, and flat place, spread the plastic film for food packaging on the ground, spread the bean slices evenly on the plastic surface, the thickness is not more than 1 cm; then cover the food packaging Use plastic wrap. Use materials such as twigs to press slightly on the edge of the plastic; the sword bean slices are exp...

Embodiment 3

[0055] Production of light-colored dehydrated beans:

[0056] From the freshly harvested sword beans, select the fresh ones that have grown fully but the seeds have not yet expanded, remove the parts with insect eyes and disease spots, and tear off the old tendons on both sides; use a stainless steel vegetable cutter or stainless steel knife to cut the knife Cut the beans into 2-3 mm thick slices; rinse the cut beans with clean water, drain the surface water, and place them in solar drying facilities (take plastic greenhouses as an example, of course glass greenhouses or The method is as follows: In fine weather, choose a sunny, dry and hygienic, flat and open site, install a plastic greenhouse, place a sun-drying mat in the greenhouse, and spread the bean slices evenly on the sun-dried mat. Thickness does not exceed 1 cm. Then close the greenhouse. The sword bean slices are exposed to sunlight in a plastic greenhouse, and the temperature rises rapidly. When the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com