Automatic production line for making charcoal from wood and production process

An automatic production line and production process technology, applied in the petroleum industry, biofuels, special forms of dry distillation, etc., can solve the problems of unstable quality, low efficiency, high energy consumption, and achieve high charcoal quality, good operating environment, and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

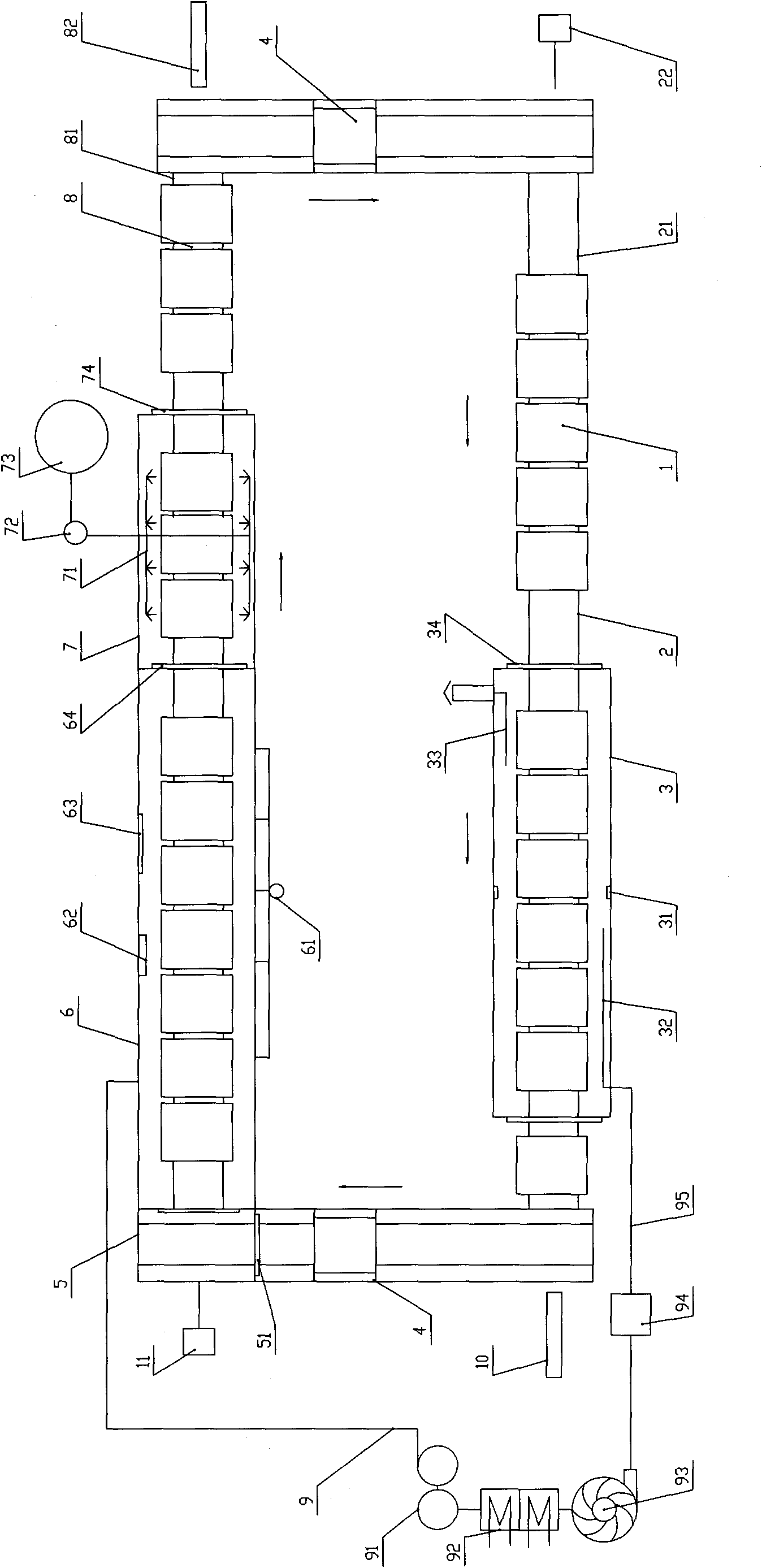

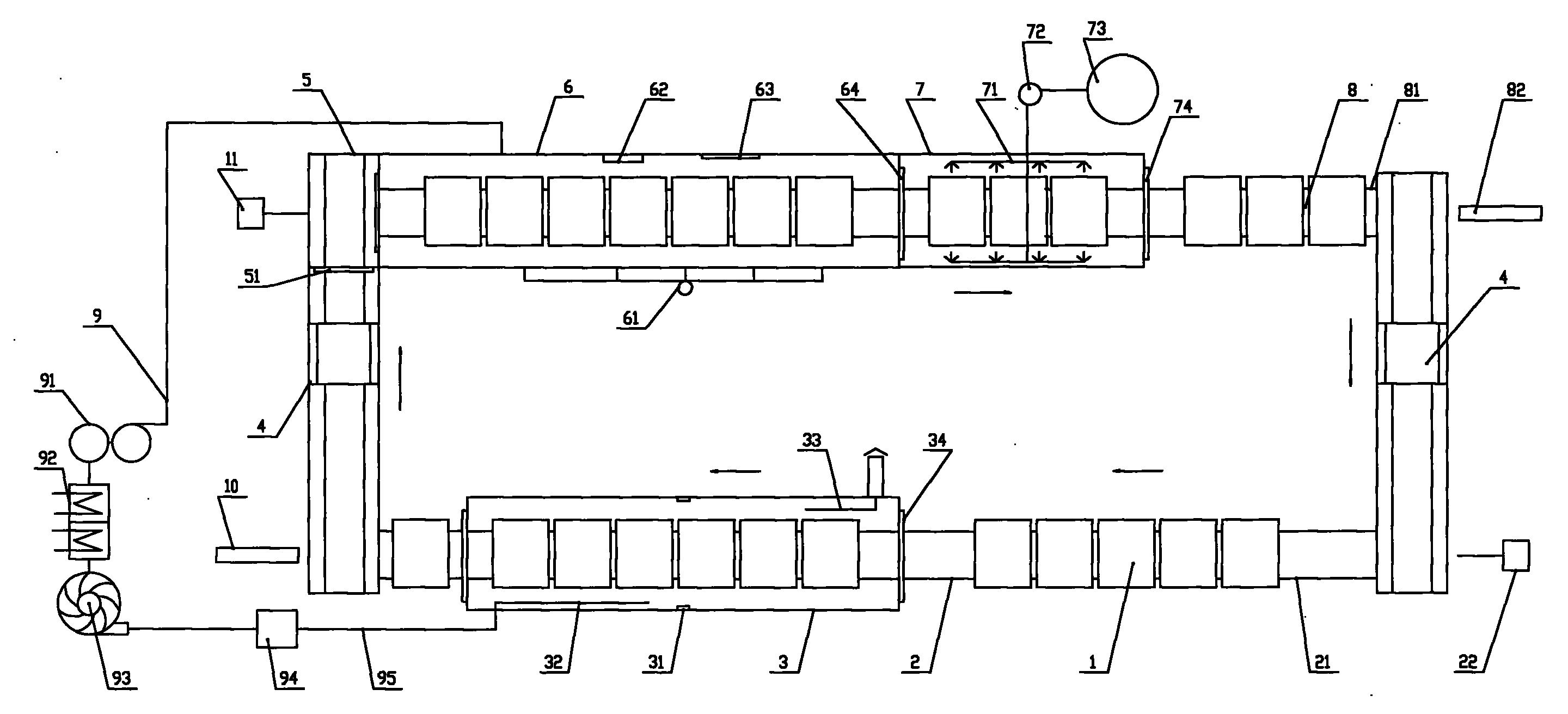

[0021] refer to figure 1 , wood charcoal automatic production line includes a plurality of wood car 1, wood car conveyor 2, drying kiln 3, pulling machine 10, trailer machine 4, transfer room 5, jacking machine 11, carbonization kiln 6, cooling kiln 7 and outlet The charcoal conveyor 8, the jacking machine 11, the transfer chamber 5, the carbonization kiln 6, the cooling kiln 7 and the charcoal conveyor 8 are connected in sequence, the cart puller 10, the drying kiln 3 and the wood car conveyor 2 are connected, and the trailer 4 passes through The drying kiln 3 is connected with the carbonization kiln 6 through the transfer chamber 5, the wood car conveyor 2 and the carbonization conveyor 8 are connected through the trailer 4, and the wood car 1 is in the drying kiln 3, the transfer chamber 5, the carbonization kiln 6 and the cooling kiln 7 The main points of its structure are: it also includes a flue gas dust removal and recovery device 9, the drying kiln 3 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com