Catalytic process for the direct production of hydrocarbon fuels from syngas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example # 1

EXAMPLE #1

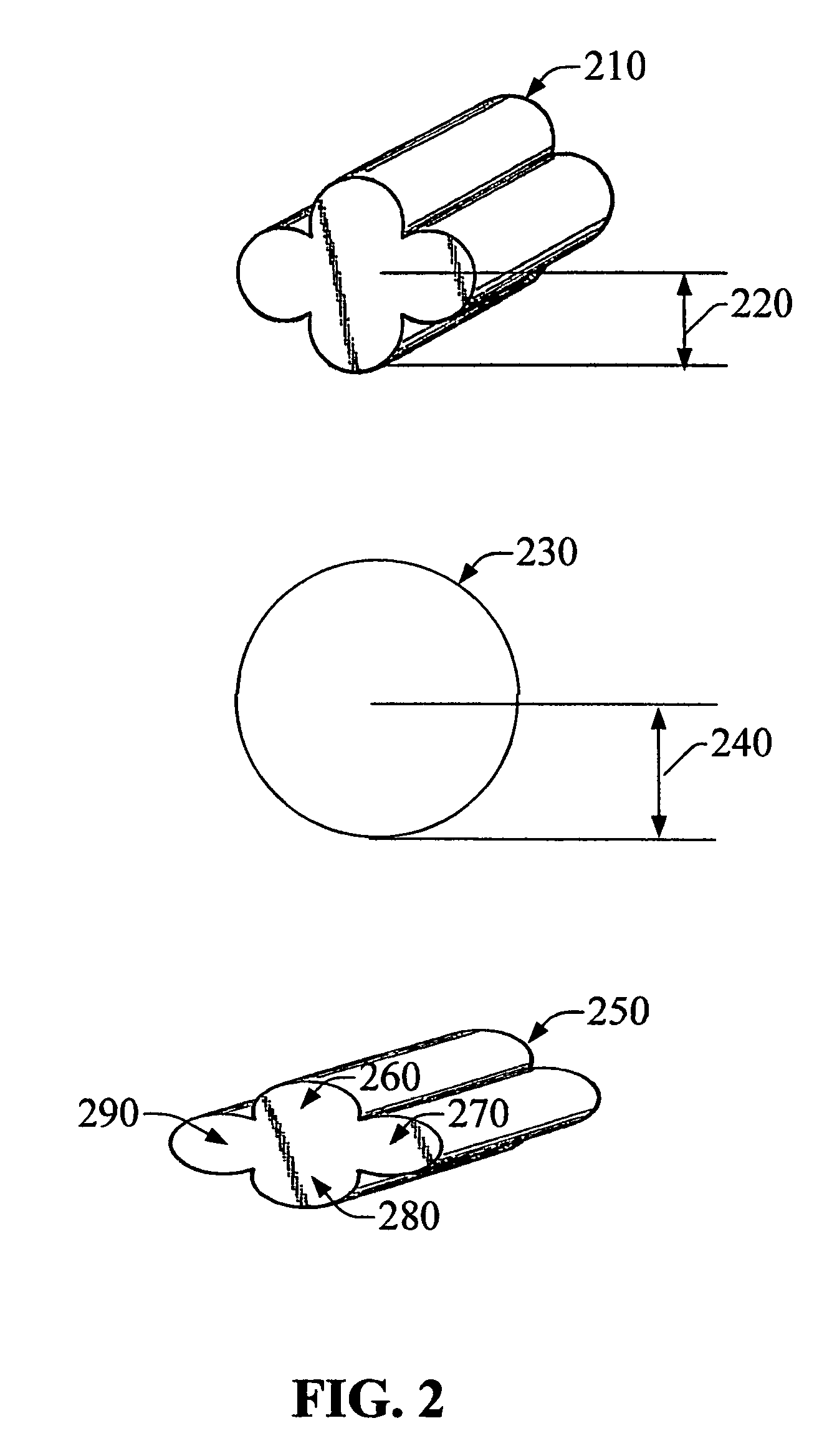

[0084]Supported catalysts are prepared using an incipient wetness procedure whereby cobalt and promoter metals are impregnated on a gamma alumina, quad-lobed support with a mean effective pellet radius of 0.25 mm and a mean pore diameter of 130 Angstroms. The surface area of the catalyst is 110 m2 / g as measured by BET / N2 physisorption technique. The crush strength of the catalyst is 4 lbs / mm. Drying and calcination steps are used in the production process to produce a catalyst with 20 wt % cobalt and 0.3 wt % platinum promoter. Following the production of the supported catalysts, the supported catalysts are loaded in a multi-tubular fixed bed reactor of a tube in shell design with 1″ (2.54 cm) diameter tubes. The catalyst is reduced with hydrogen at 75 psig and at a temperature less than 550° F. which are operating conditions that can be achieved in a fixed bed reactor that can be manufactured inexpensively.

[0085]In an alternative embodiment, the catalyst is reduced with a...

example # 2

EXAMPLE #2

[0090]In this example, improved cold flow properties of the diesel fuel fraction are desired. The same catalyst system and processes are used as described above in Example #1. Following the catalyst synthesis process, the diesel fuel fraction is contacted with a catalyst that performs isomerization under mild operating conditions, while minimizing cracking functions. In this example, the catalyst used is a platinum promoted tungstate-modified zirconia.

[0091]In this example, a trickle bed reactor is used; however, other known reactors can be used as well. The reactor is operated in a pressure range of about 100 psi to about 400 psi, ideally at 150 psi in a temperature range of about 350° F. to about 600° F., preferably at 425° F. The H2 / diesel fuel molar ratio is estimated using C16 (hexadecane) as an average compound of the diesel fuel and the H2 / n-C16 ratio is in the range of 1.5-5, preferably equal to 2 (therein requiring 22 standard cubic feet of H2 per gallon of n-C16 ...

example # 3

EXAMPLE #3

[0093]The cold flow properties of a diesel fuel fraction are improved by splash blending the diesel fuel fraction with a cold flow improver. The same catalyst system and processes are used as described above in Example #1. Following the catalyst synthesis process, the diesel fuel fraction is splash blended with a cold flow improver that is blended at 2000 ppm and consists of alkyl-methacrylate copolymers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com