Method for preparing dimethyl silicone polymer by hydrolyzing dimethyl dichlorosilane with concentrated acid

A technology of dimethyldichlorosilane and polydimethylsiloxane, which is applied in the field of preparing polydimethylsiloxane by hydrolyzing dimethyldichlorosilane with concentrated acid, and can solve the problem of low content of polysiloxane rings To achieve the effect of increasing the content of ring body, promoting the separation of oil phase and reducing the probability of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

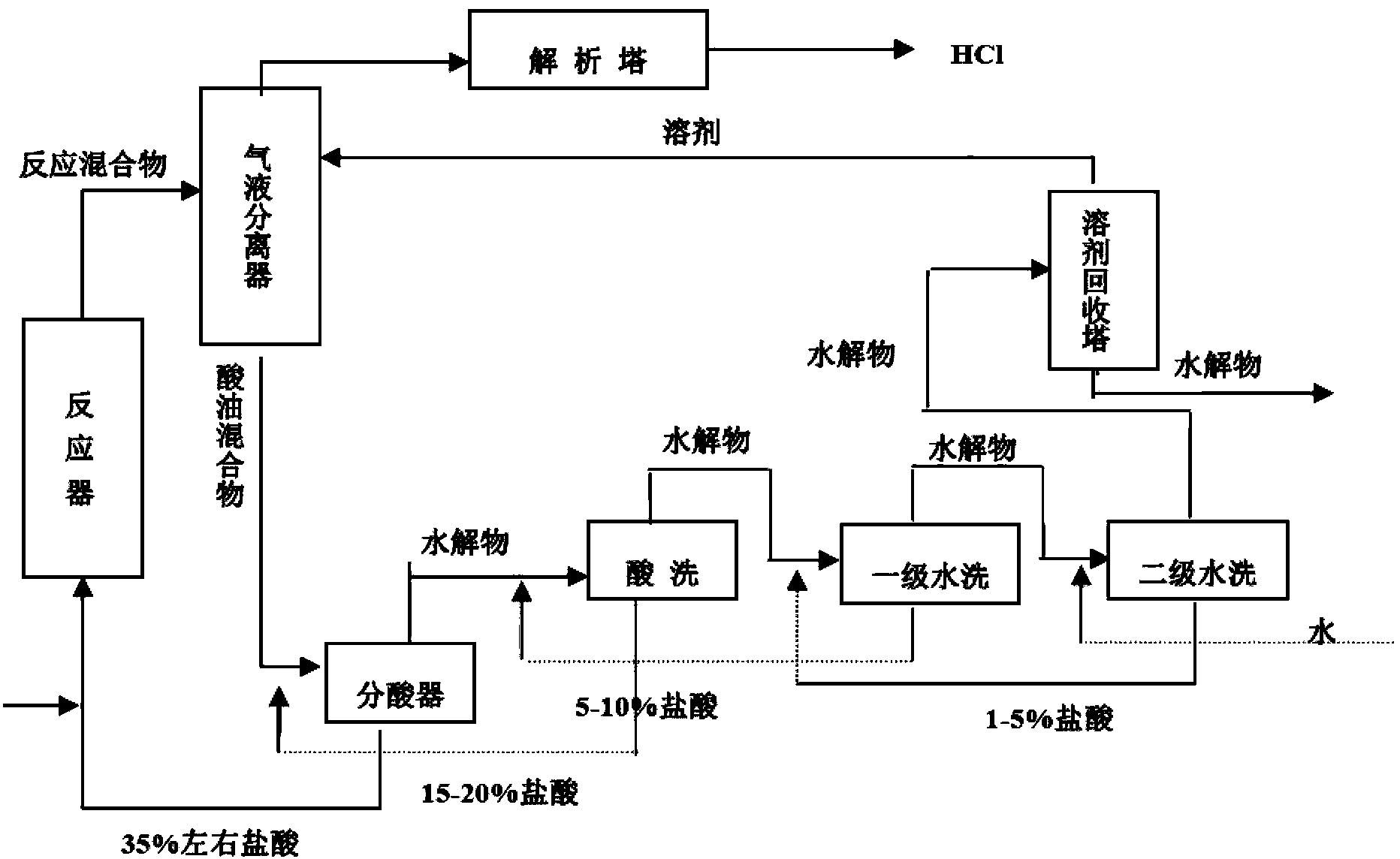

Method used

Image

Examples

Embodiment 1

[0032] Hydrolysis reaction

[0033] 2000kg / hr dimethyldichlorosilane and 20000kg / hr concentrated hydrochloric acid with a concentration of 38% enter the packed tower reactor for hydrolysis reaction, the temperature is 25°C, the operating pressure is 0.2MPa, and the residence time is 134s. After the reaction The mixture and the heptane of 27.5kg / hr enter the gas-liquid separator for gas-liquid separation, and the separated wet hydrogen chloride enters the desorption tower for analysis, and the obtained sour oil mixture 21120kg / hr enters the acid separator.

[0034] Acid

[0035] 21120kg / hr acid-oil mixture and 400kg / hr, dilute hydrochloric acid obtained from pickling enter the static mixer together, after being fully mixed, enter the gravity sedimentation separator, the system temperature is controlled at 32°C, and the mixture is separated to obtain a hydrolyzate of 1400kg / hr , the obtained hydrochloric acid enters the upper packed column reactor for recycling.

[0036] pickl...

Embodiment 2

[0045] Hydrolysis reaction

[0046]2000kg / hr dimethyldichlorosilane and 30000kg / hr circulating concentrated hydrochloric acid with a concentration of 40% enter the packed tower reactor for hydrolysis reaction, the temperature is 35°C, the operating pressure is 0.3MPa, and the residence time is 200s. The reacted mixture enters the gas-liquid separator together with 45 kg / hr of heptane for gas-liquid separation. The separated wet hydrogen chloride enters the desorption tower for desorption. The obtained sour oil mixture 31232kg / hr enters the acid separator.

[0047] Acid

[0048] 31232kg / hr acid oil mixture and 600kg / hr, dilute hydrochloric acid obtained from pickling enter the static mixer together, and enter the gravity sedimentation separator after thorough mixing, the system temperature is controlled at 37 °C, and the mixture is phase separated to obtain hydrolyzate 1430kg / hr , the obtained hydrochloric acid enters the upper packed column reactor for recycling.

[0049] ...

Embodiment 3

[0058] Hydrolysis reaction

[0059] 2000kg / hr dimethyldichlorosilane and 40000kg / hr circulating concentrated hydrochloric acid with a concentration of 42.9% enter the packed tower reactor for hydrolysis reaction at a temperature of 45°C, an operating pressure of 0.4MPa, and a residence time of 268s. The reacted mixture enters the gas-liquid separator together with 68 kg / hr of heptane for gas-liquid separation. The separated wet hydrogen chloride enters the desorption tower for desorption. Obtain sour oil mixture 41141kg / hr into the acid divider.

[0060] Acid

[0061] 41141kg / hr acid oil mixture and 2200kg / hr, dilute hydrochloric acid obtained from pickling enter the static mixer together, and enter the gravity sedimentation separator after thorough mixing, the system temperature is controlled at 42 °C, and the mixture is phase separated to obtain hydrolyzate 1510kg / hr , the obtained hydrochloric acid enters the upper packed column reactor for recycling.

[0062] pickling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com