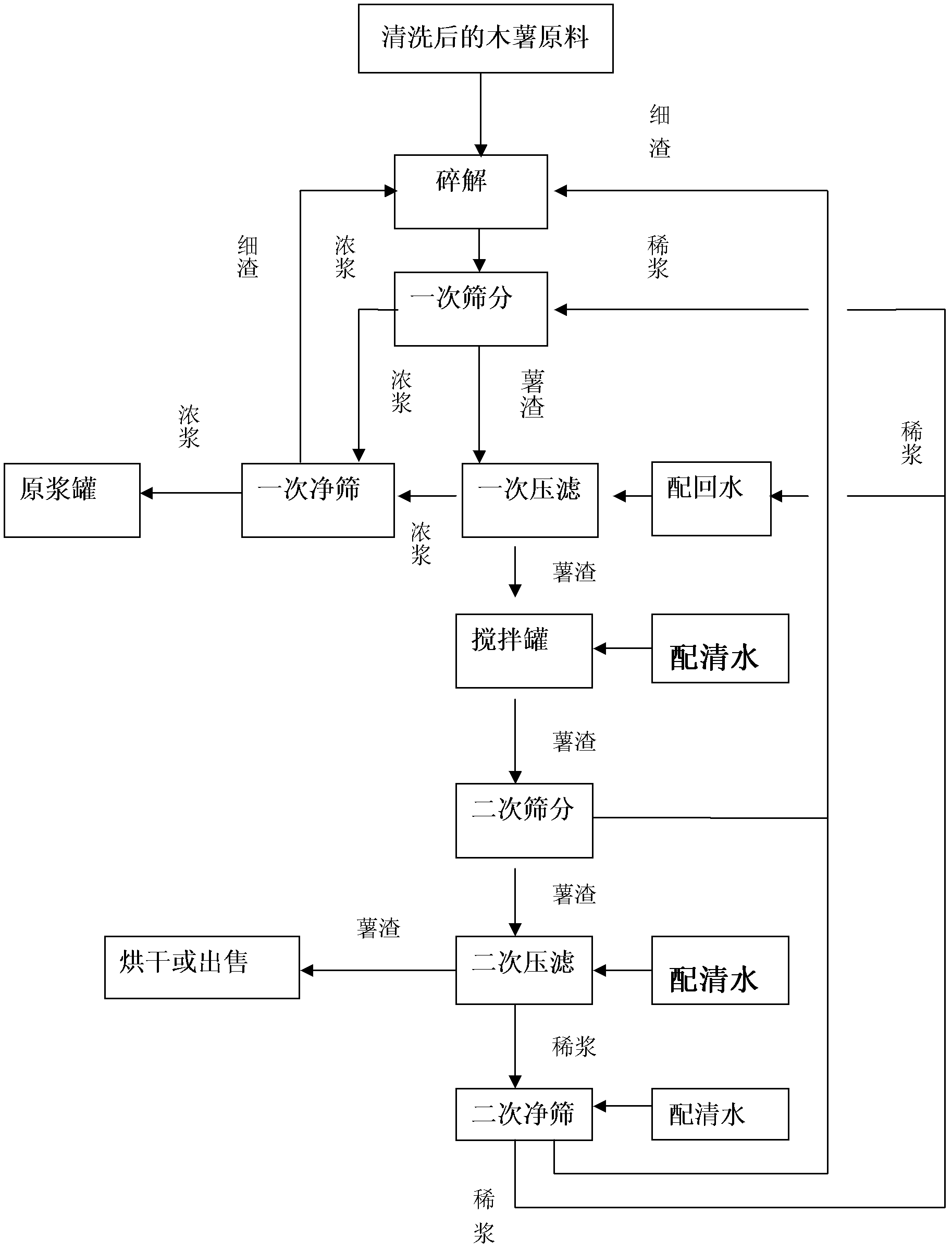

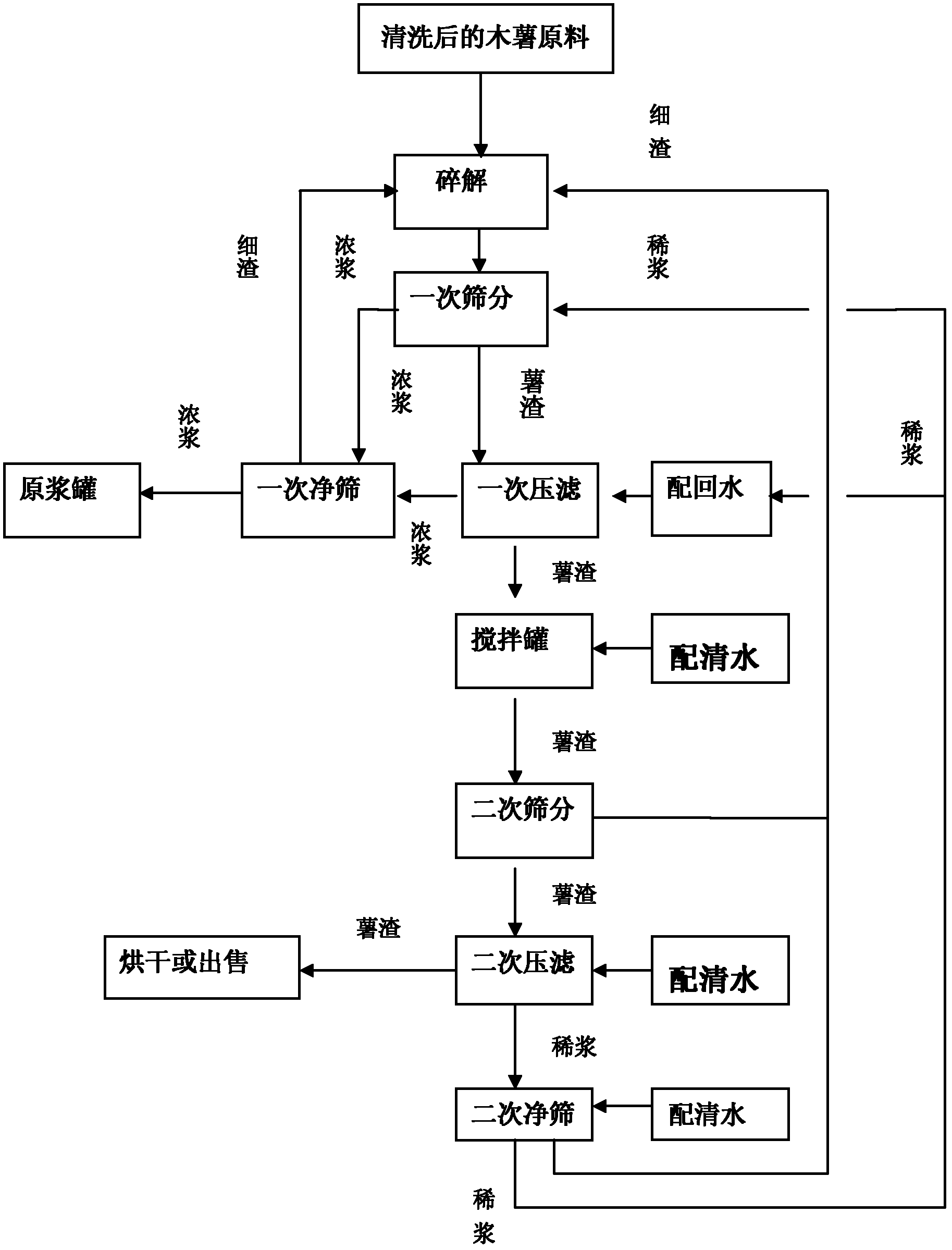

Tuberous starch slurry-residue separation technique by screening and pressure filtration

A process method and screening technology, which is applied in the field of separation of potato starch pulp and residue, can solve the problems of complex separation process of potato starch pulp and residue, high operating cost, etc., to improve the separation effect of pulp and residue, use less equipment, and reduce labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Example: The slurry is pumped into the primary vertical sieve at the highest point of the process. After screening, the slurry flows into the primary net sieve for screening, and the sieved slurry flows into the raw slurry tank and enters the next process. The primary vertical sieve The slag produced by the centrifugal force falls directly into the primary filter press, and the slag is further pressed dry, so that more starch emulsion is separated from the slag. Flow into the net sieve together, continue to sieve and separate, the slurry screened out by the net sieve flows into the slurry tank, and the whey enters the raw pulp tank and enters a process. The slag pressed out of the primary filter press falls into the mixing tank, and at the same time, it is stirred with clean water, and flows into the secondary vertical sieve through the pipeline through the high-level difference for centrifugation. , used for water distribution of the primary and secondary pulverizers t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com