Method for manufacturing cable for high-temperature gas cooled reactor

A high-temperature gas-cooled reactor and cable manufacturing technology, which is applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuits, etc., can solve the problems that cables cannot meet the ambient temperature and high conductivity, and achieve excellent mechanical and physical properties and high volume The effect of high resistivity and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

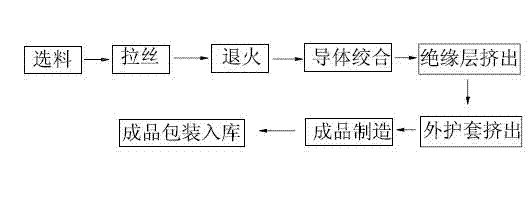

[0022] A cable manufacturing method for high-temperature gas-cooled reactors, including material selection-wire drawing-conductor stranding-finished product manufacturing-finished product packaging and warehousing process, and also includes annealing-insulating layer extrusion-outer sheath extrusion manufacturing process ; The annealing means that the surface of the copper monofilament is plated with 6 μm silver through an annealing silver plating machine; There is a good cooling device, and the extrusion processing temperature is controlled at 360°C. The extrusion die is a pipe extrusion die with a high draw ratio, and the selected draw ratio is 30.

[0023] The wire drawing refers to drawing a copper monofilament from an electrical round copper rod through a plurality of drawing dies of the drawing equipment.

[0024] The conductor stranding refers to concentric stranding of multiple strands of silver-plated copper wires with a stranding pitch range of 10 mm.

[0025] In th...

Embodiment 2

[0030] A cable manufacturing method for high-temperature gas-cooled reactors, including material selection-wire drawing-conductor stranding-finished product manufacturing-finished product packaging and warehousing process, and also includes annealing-insulating layer extrusion-outer sheath extrusion manufacturing process The annealing refers to the copper monofilament with a thickness of 10 μm silver plated on the surface of the copper monofilament through an annealing silver plating machine; the extrusion of the insulating layer and the extrusion of the outer sheath refer to the use of a screw with a high compression ratio of 4.0:1, and the extrusion equipment There is a good cooling device, the extrusion processing temperature is 380°C, and the extrusion die is a pipe extrusion die with a high draw ratio, and the selected draw ratio is 35.

[0031] The wire drawing refers to drawing a copper monofilament from an electrical round copper rod through a plurality of drawing dies ...

Embodiment 3

[0038] A cable manufacturing method for high-temperature gas-cooled reactors, including material selection-wire drawing-conductor stranding-finished product manufacturing-finished product packaging and warehousing process, and also includes annealing-insulating layer extrusion-outer sheath extrusion manufacturing process ; The annealing means that the surface of the copper monofilament is plated with 15 μm silver through the annealing silver plating machine; There is a good cooling device, the extrusion processing temperature is 400 ℃, and the extrusion die is a pipe extrusion die with a high stretch ratio, and the selected stretch ratio is 45.

[0039] The wire drawing refers to drawing a copper monofilament from an electrical round copper rod through a plurality of drawing dies of the drawing equipment.

[0040]The conductor stranding refers to concentric stranding of multiple strands of silver-plated copper wires, with a stranding pitch range of 30mm.

[0041] In the wire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com