Air-actuated plastic injection machine

An injection molding machine and pneumatic technology, which is applied in the field of pneumatic injection molding machines, can solve the problems that the equipment cannot be miniaturized, cannot meet the requirements of molding precision, and consumes a large amount of cooling water, so as to facilitate centralized management and maintenance, facilitate large-scale flow production, and save The effect of the production site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

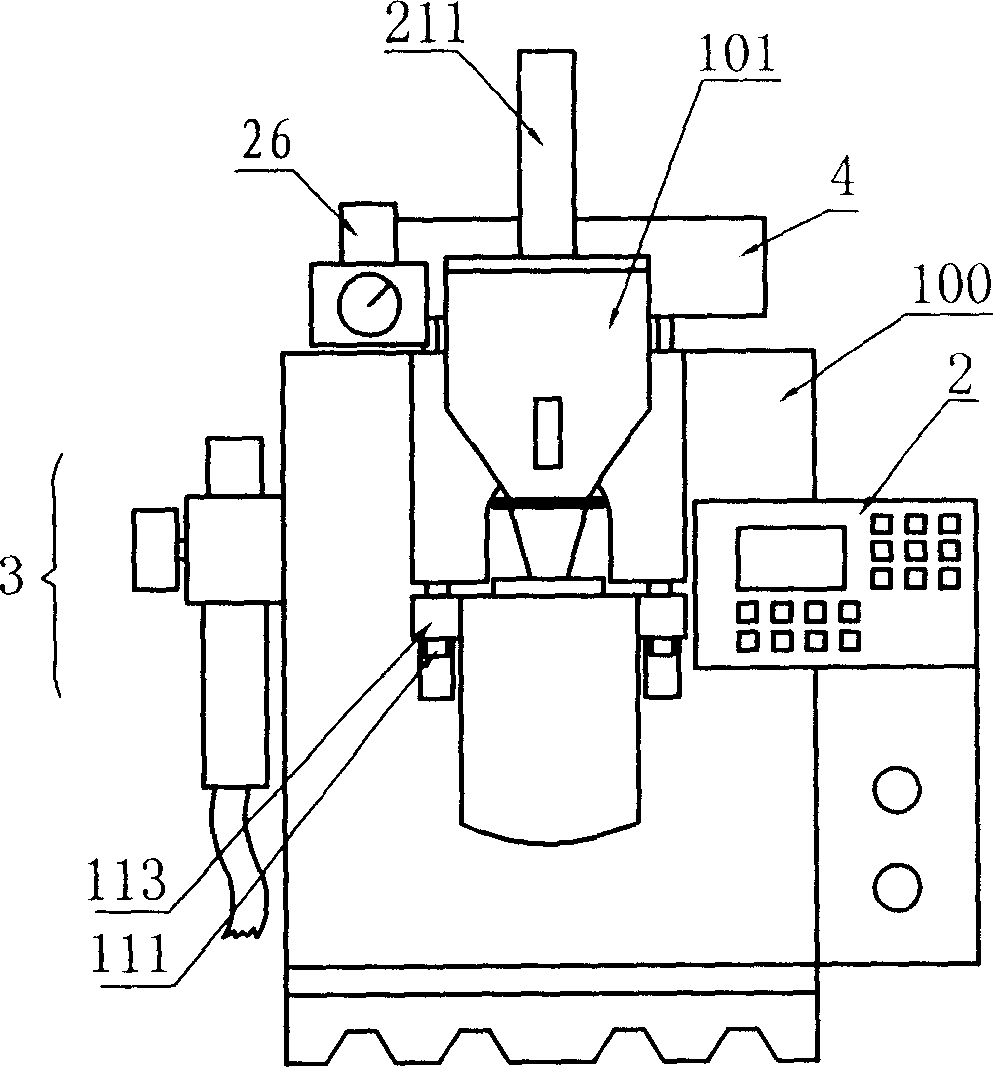

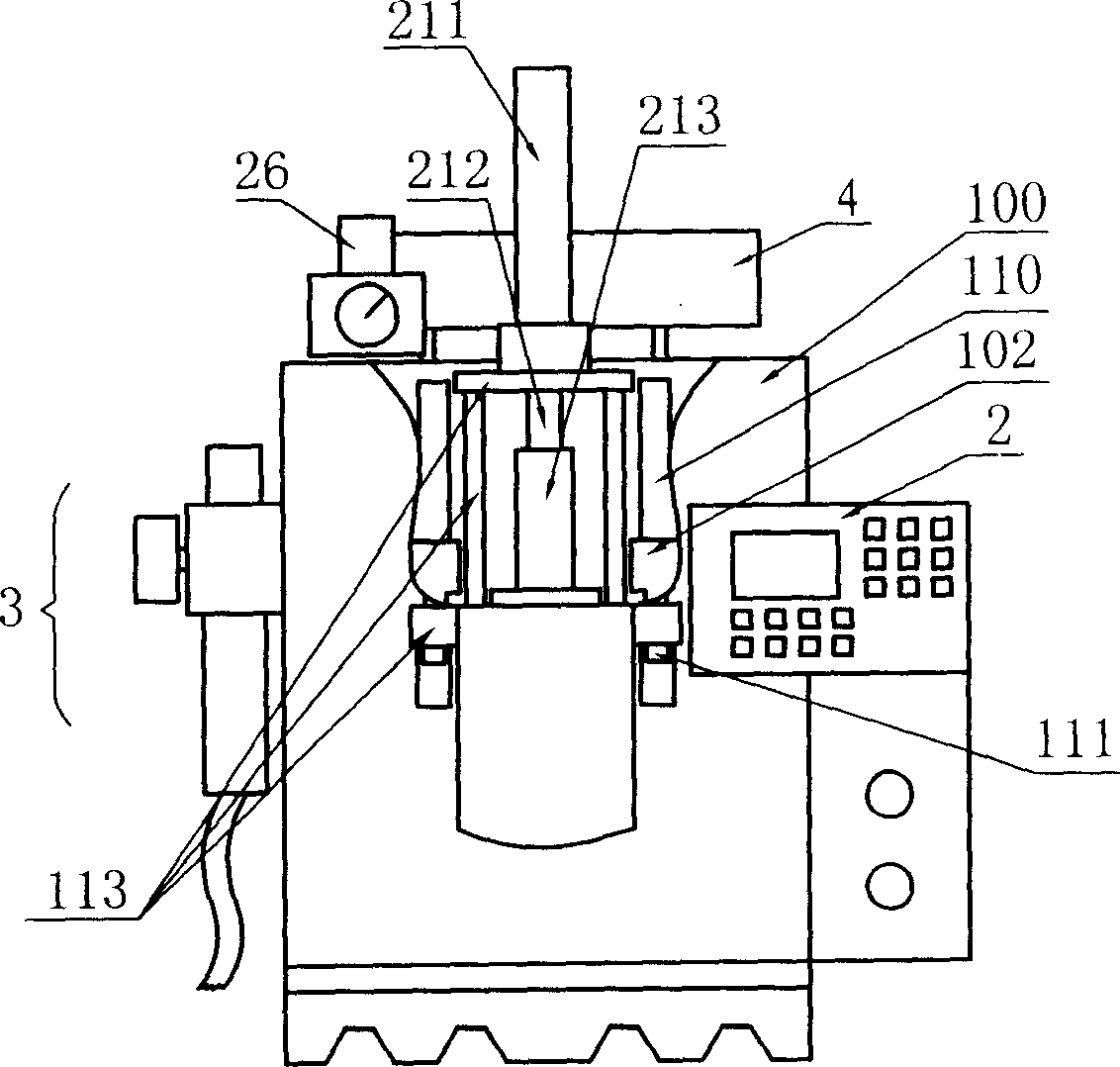

[0038] The following takes a vertical pneumatic injection molding machine as an example, combined with the schematic diagram of the connection of the pneumatic working parts of the pneumatic injection molding machine of the present invention and the accompanying drawings of the embodiment, the specific implementation of the pneumatic injection molding machine is described in detail;

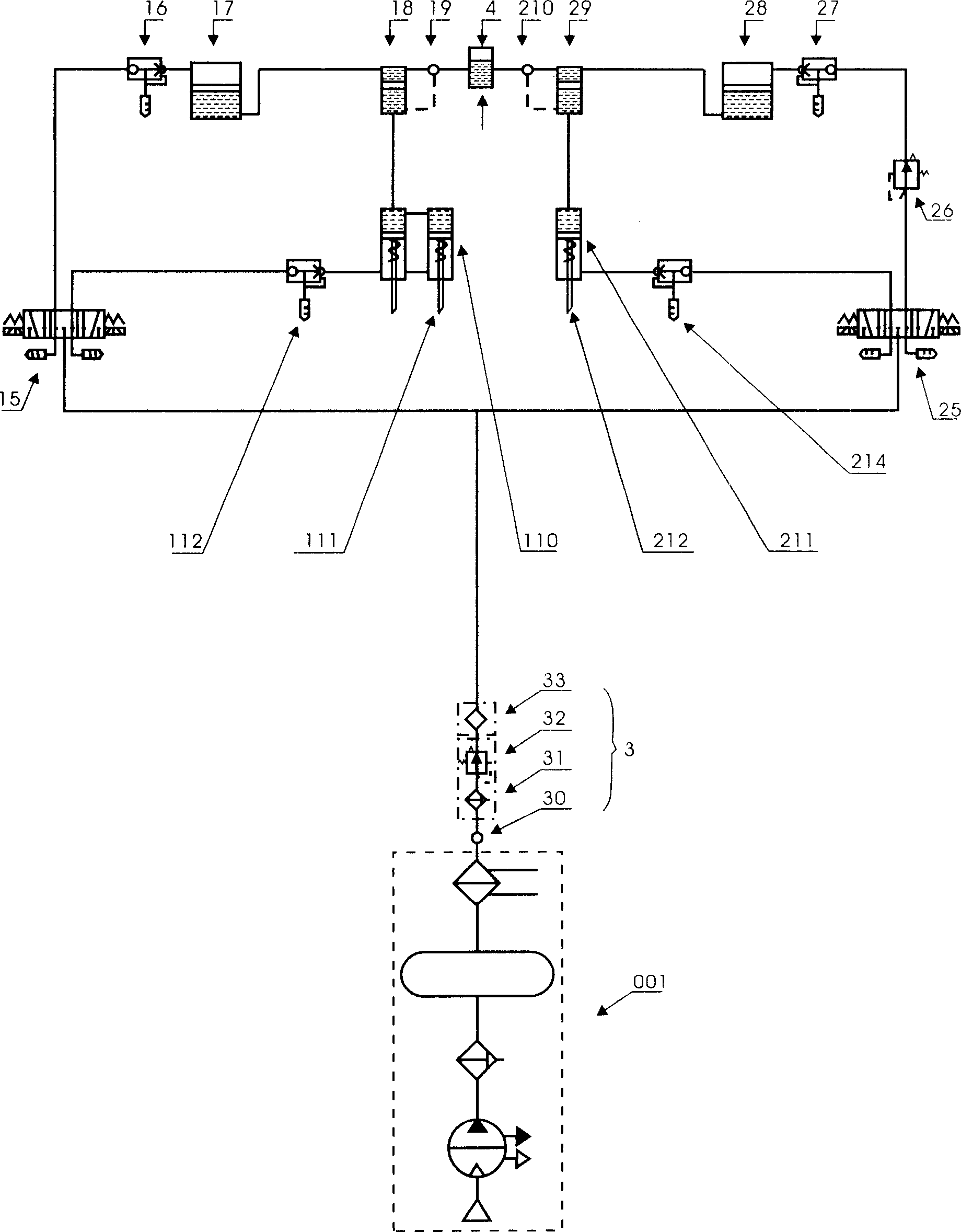

[0039] figure 1 It is a schematic diagram of the pneumatic working parts and connections of the pneumatic injection molding machine of the present invention, and the pneumatic composition of the vertical pneumatic injection molding machine is also as follows figure 1 As shown, it includes an intake valve 30, a filter 3, a pneumatic injection / rod withdrawal branch, and a pneumatic mold opening / closing branch.

[0040] The intake valve 30 inputs the power compressed air pumped in by the central air pump station 001 after preliminary filtration, pressure stabilization and drying, and enters the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com