Cable mold capable of realizing highly compact and uniform extrusion molding

A compact and cable technology, applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problems of insufficient bonding fastness, affecting the electrical and mechanical properties of wires and cables, and bulkiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

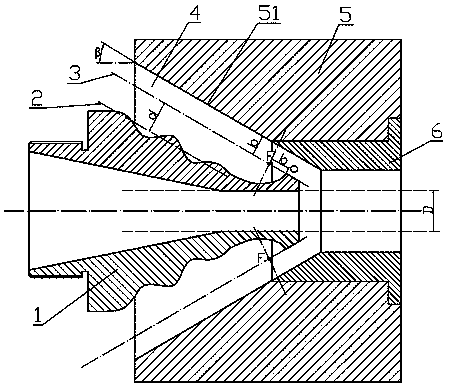

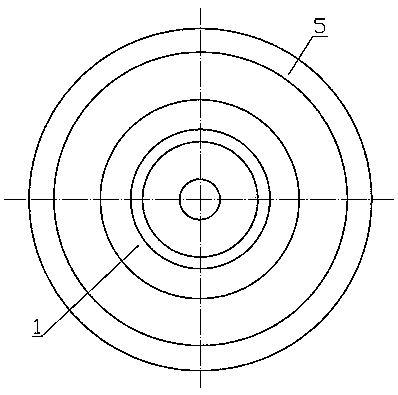

[0023] Such as figure 1 , figure 2 Shown is a cable mold for highly dense and uniform extrusion. The cable mold includes a mold core 1 and a mold sleeve 5. The working part of the mold core 1 is located in the mold sleeve guide hole 51 of the mold sleeve 5. The working part of the mold core 1 Extrusion runner 4 is formed between the outer surface of the mold cover 5 and the mold cover guide taper hole 51 of the die cover 5, and a detachable embedded sizing insert 6 is also installed on the die cover 5. The axis line of the mold core 1, the center line of the mold sleeve guide hole 51 and the axis line of the shaped nest 6 are on the same straight line, and the shaped nest 6 is located at the front end of the mold core 1.

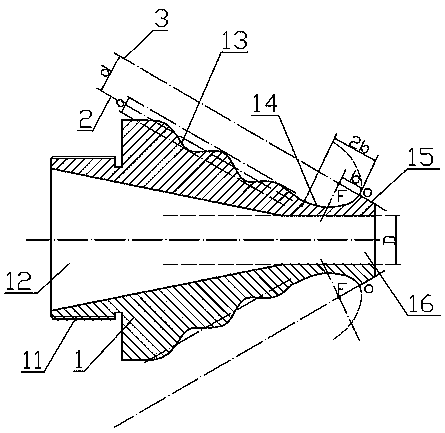

[0024] Such as image 3As shown, the front part of the mold core 1 is the working part, and the working part extends into the mold sleeve guide material taper hole 51 of the mold sleeve 5 , and the rear end of the mold core 1 is provided with a mold core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com