Plastic extruding and pelleting unit

A technology of granulation unit and extruder, which is applied in the direction of coating, etc., can solve the problems of taking a long time, insufficient plasticization of recycled plastics, and reducing production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

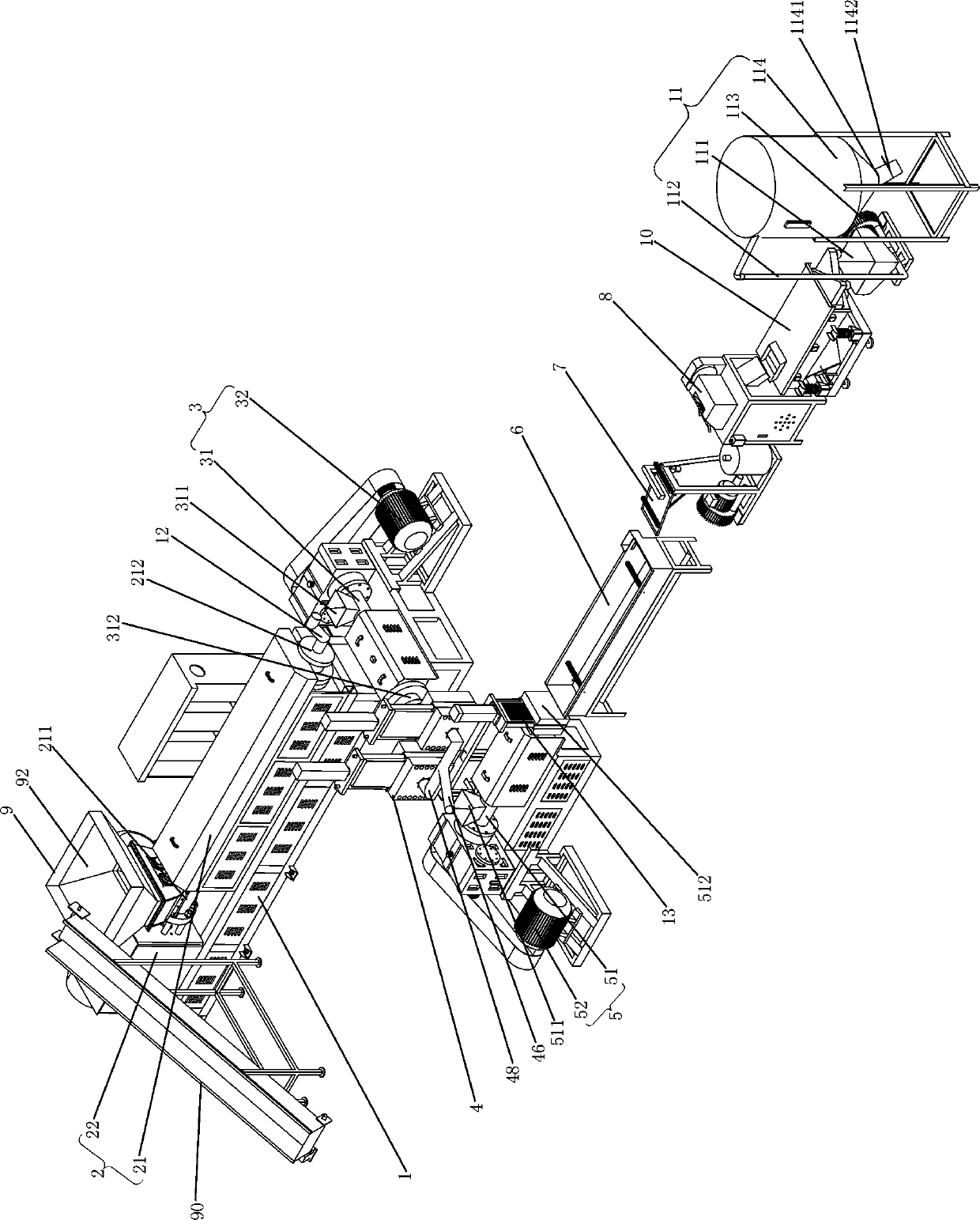

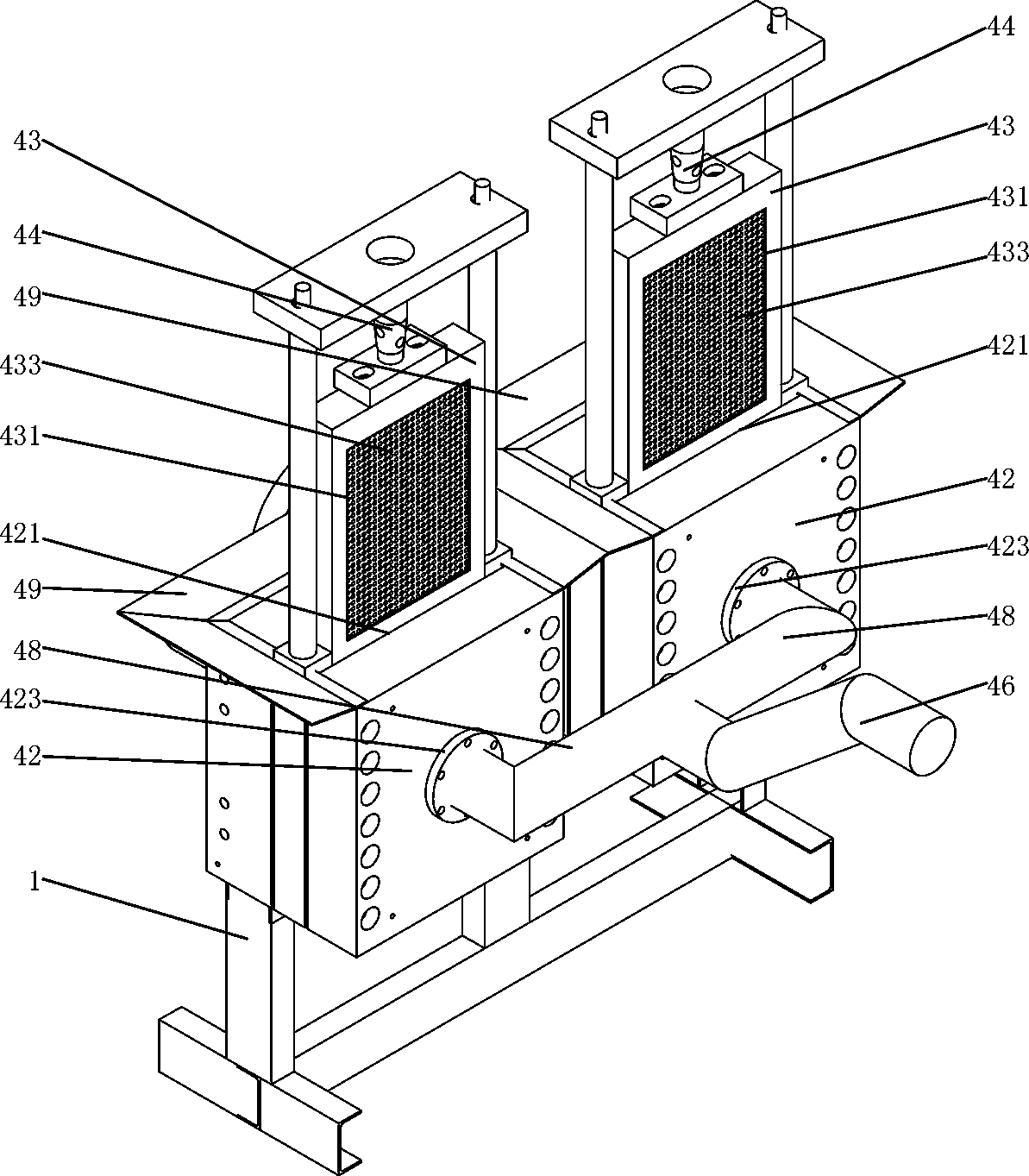

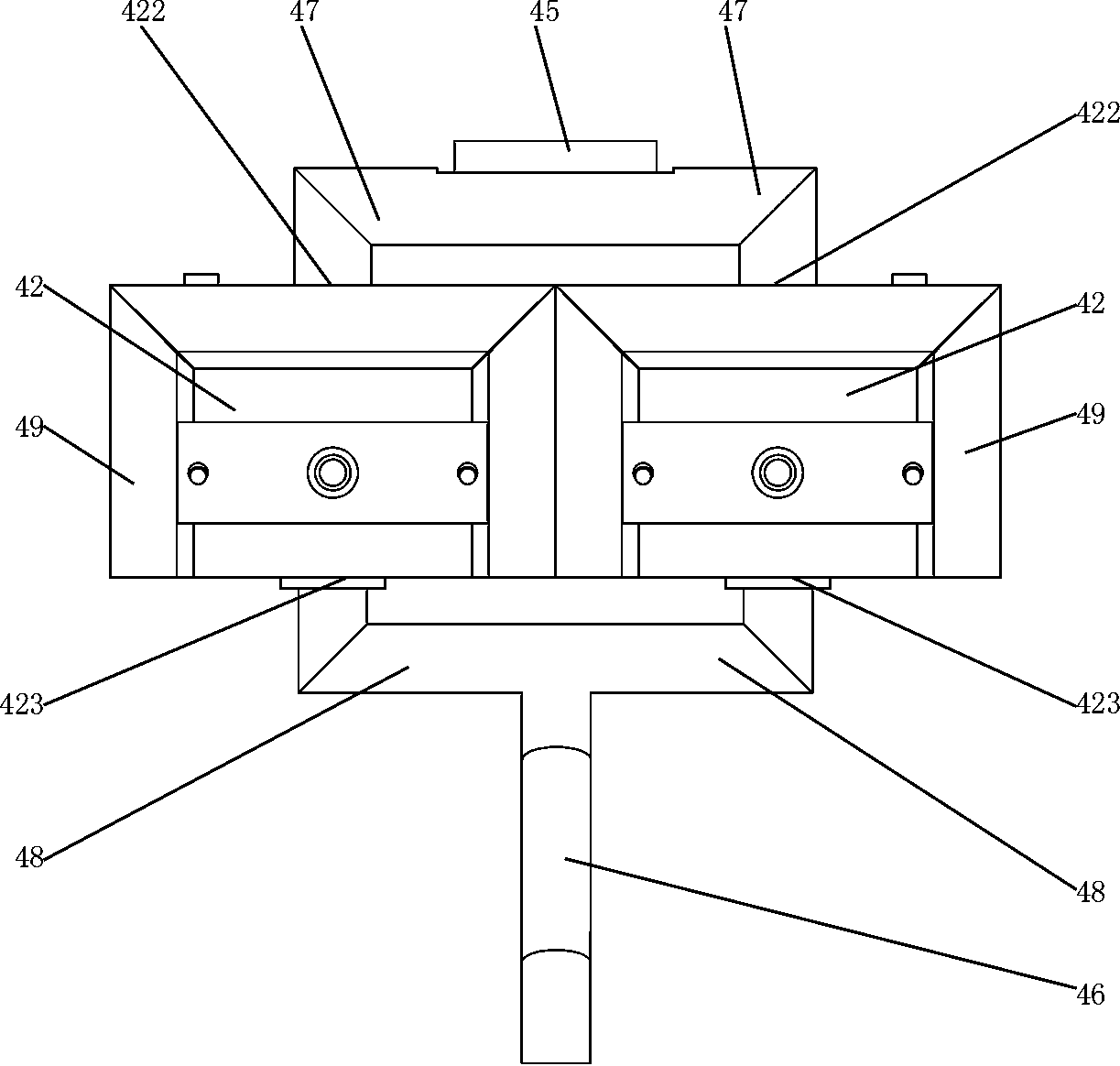

[0041] Such as figure 1 As shown, this plastic extrusion granulation unit includes a frame 1, a main extruder 2, a third extruder 3, a first screen changing device 4, a second extruder 5, a cooling water tank 6, and strip removal Water device 7 and granulation device 8, main extruder 2, third extruder 3, first screen changing device 4, second extruder 5, cooling water tank 6, strip dewatering device 7 and granulation device 8 are all installed on the frame 1 and arranged in sequence from front to back; the main extruder 2 includes a main barrel 21 and a main driving device 22, and the main barrel 21 is provided with two main screws rotating in different directions, and the two main screws The threads are opposite in direction and meshed with each other, and the two main screws are connected to the main driving device 22. The front end of the main barrel 21 is provided with a main feed port 211, and the rear end of the main barrel 21 is connected with a main die head 212; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com