Organotin leadless sectional materials

A technology of tin-lead-free profiles and organic tin, which is applied in the field of building envelope materials, can solve environmental pollution and other problems, and achieve the effects of reducing energy consumption, good weather resistance, and improving solder fillet strength and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: Get 100 parts of PVC, 1.3 parts of organotin stabilizer, 8 parts of titanium dioxide, 8 parts of chlorinated polyethylene, 6 parts of activated calcium carbonate, 1.3 parts of ACR processing modifier, 1.2 parts of calcium stearate, oxidized polystyrene 0.2 parts of ethylene wax, 0.8 parts of Sasol wax.

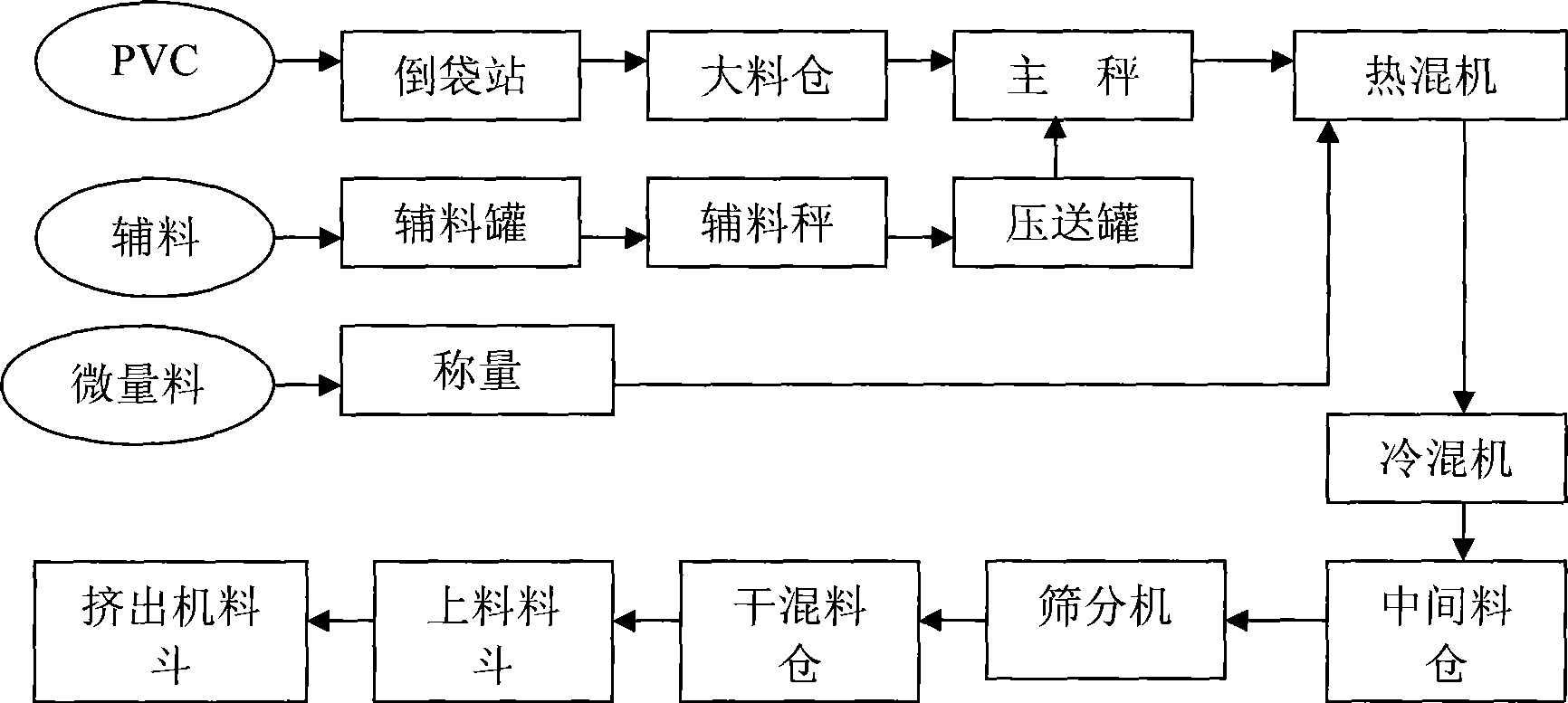

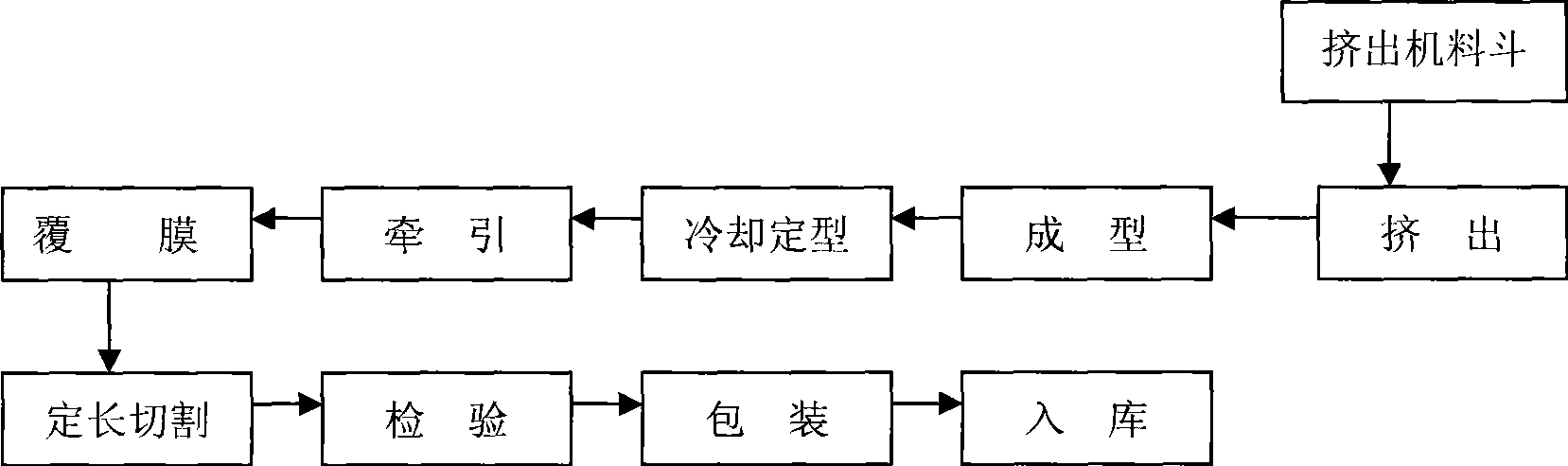

[0041]The above-mentioned materials are mixed according to the following process to make a dry blend, and the process flow is as follows: figure 1 Shown:

[0042] First, the mixture was prepared by using the German Lemet automatic mixing system. The preparation process is as follows:

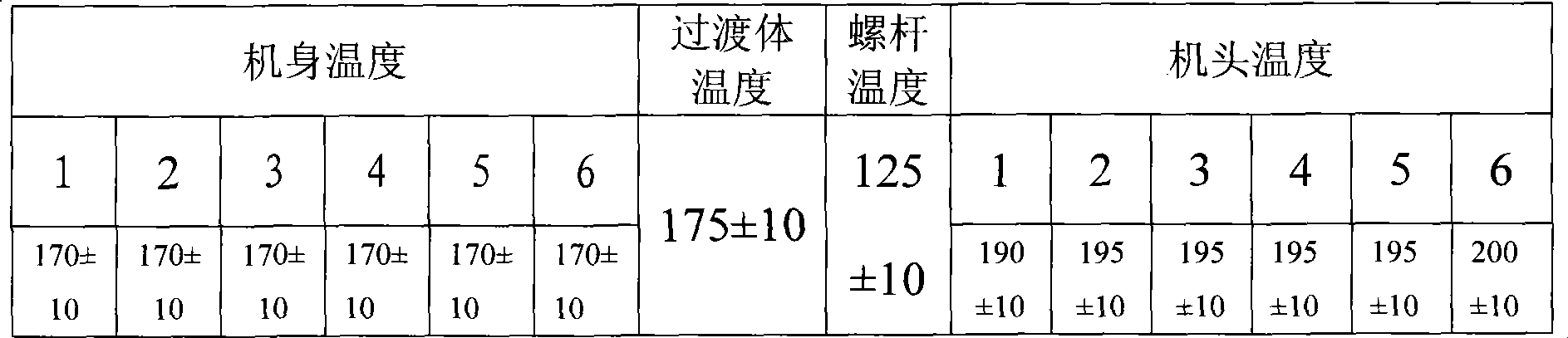

[0043] The main material PVC enters the PVC silo through the bag dumping station, and then is sent to the main scale by air. The auxiliary materials chlorinated polyethylene, ACR processing modifier, calcium stearate, titanium dioxide, and active calcium carbonate enter the auxiliary material scale through their respective auxiliary material tanks for weighing. scales. ...

Embodiment 2

[0051] Embodiment 2: Get 100 parts of PVC, 1.5 parts of organotin stabilizer, 8 parts of titanium dioxide, 8 parts of chlorinated polyethylene, 8 parts of activated calcium carbonate, 1.3 parts of ACR processing modifier, 1.2 parts of calcium stearate, oxidized poly 0.2 parts of ethylene wax, 0.8 parts of Sasol wax. Operation is with embodiment 1.

Embodiment 3

[0052] Embodiment 3: Get 100 parts of PVC, 1.5 parts of organotin stabilizer, 8 parts of titanium dioxide, 10 parts of chlorinated polyethylene, 8 parts of activated calcium carbonate, 1.3 parts of ACR processing modifier, 1.2 parts of calcium stearate, oxidized poly 0.2 parts of ethylene wax, 0.8 parts of Sasol wax. Operation is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com