Solid electrolyte film material, preparation method thereof, and battery

A technology of solid electrolyte and thin film material, applied in the energy field, can solve the problems of increasing ionic conductivity and mechanical properties, waste, solvent pollution, etc., achieve good electrochemical performance, improve ionic conductivity, and ensure the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the solid electrolyte thin film material of one embodiment of the present invention comprises the following steps: mixing polyethylene oxide, complex lithium salt, structural support polymer, silane coupling agent, antioxidant, thermal stabilizer and dispersant, Then extruding and calendering to form a film through a stretching rheological extrusion process to obtain a solid electrolyte film material. Wherein, the structural supporting polymer is one or more of polyethylene, vinylidene fluoride-hexafluoropropylene copolymer, polyvinyl chloride, and ethylene-(meth)acrylate polymer.

[0020] The solid electrolyte film material of the present invention is formulated to be optimized, and on the basis of polyethylene oxide, a structural supporting polymer is selectively added to make up for the mechanical properties of the PEO-lithium salt system. And through the stretching rheological extruder to process under the stretching flow field, the volume ...

Embodiment 1

[0034] Under the protection of nitrogen, 4 g of cyclohexane-1,4-dicarbonitrile was dissolved in 100 ml of tetrahydrofuran, and the temperature was lowered to -10°C. Then 20 mL of trifluoromethanesulfonic acid was added dropwise and stirred for 1 hour, keeping the reaction temperature at -10°C. Raise the temperature to reflux temperature, reflux for 1 hour, and wash with 1M sodium hydroxide solution to remove residual acid. The white or light yellow powder was obtained by filtration, washed with water and ethanol, and dried in vacuum at 110° C. to obtain a nitrogen-rich porous organic framework polymer.

[0035] In a glove box (or other dry environment), mix 12g of lithium salt with 2g of treating agent and 4g of nitrogen-rich porous organic framework polymer, and heat and stir for 1 hour under the action of a small amount of acetonitrile (10150ml). The solvent was then removed by distillation under reduced pressure, and vacuum-dried at 120° C. for 24 hours. The dried product...

Embodiment 2

[0038] The scheme of this embodiment is basically the same as that of Embodiment 1, except that the complex lithium salt is 0.52 mol (calculated according to lithium ions, EO / Li is 11).

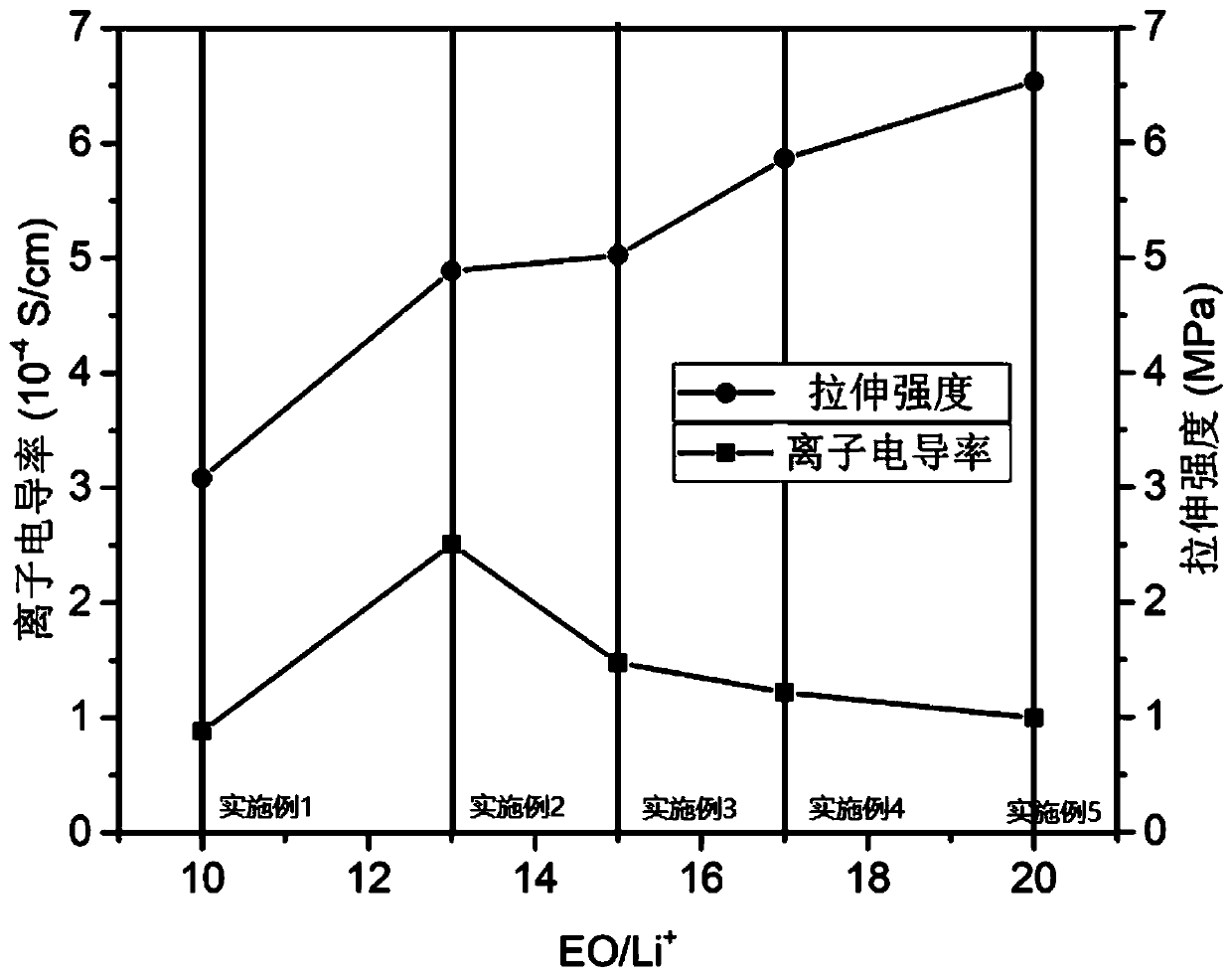

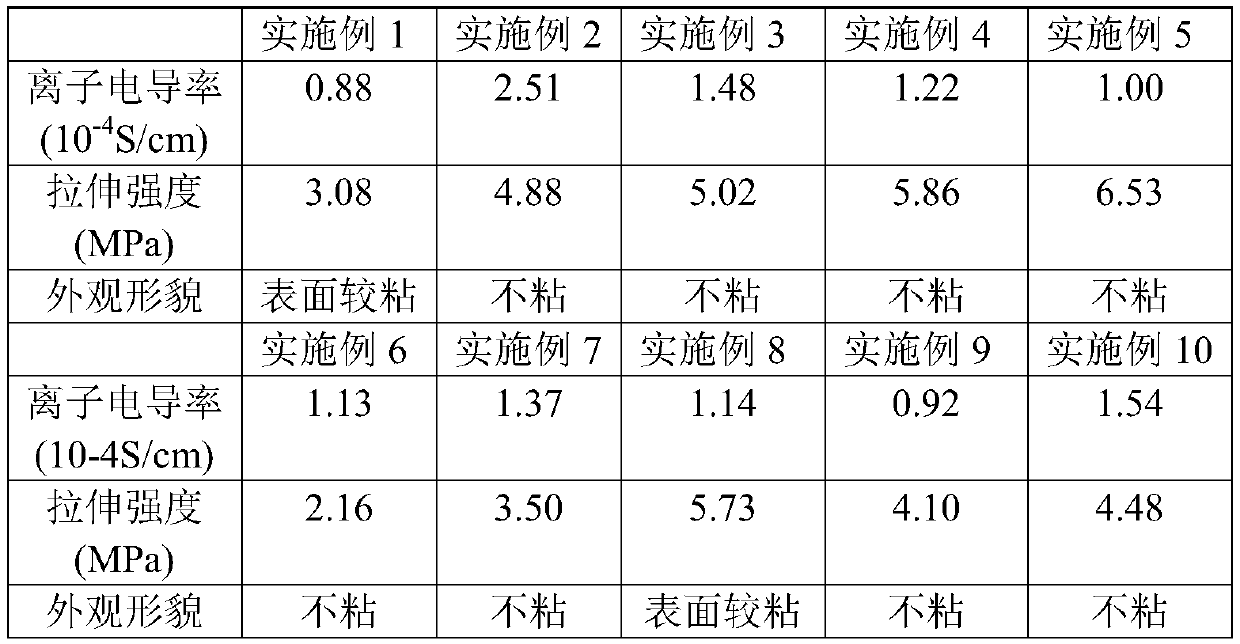

[0039] Example 1

[0040] The scheme of this embodiment is basically the same as that of Embodiment 1, except that the complex lithium salt is 0.45 mol (calculated according to lithium ions, EO / Li is 15).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com