Explosion-proof tire

A technology for run-flat tires and tires, applied in special tires, tire parts, coatings, etc., can solve problems such as threatening driving safety and great danger, and achieve the effects of anti-deformation and stability performance, improving service life, and improving explosion-proof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

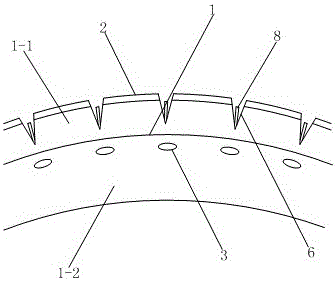

[0030] This embodiment proposes a kind of run-flat tire, comprises the tire body that is made of tread 1, carcass, buffer layer, bead, as figure 1 As shown, in the structure of the tire body, the tread 1 is bonded and synthesized by double-layer rubber layers, and an explosion-proof layer 2 made of high-molecular explosion-proof material is sprayed on the outer rubber layer 1-1, and the inner rubber layer 1 -2 is provided with several capsule cavities 3, and the capsule cavities 3 are provided with leak-tight glue.

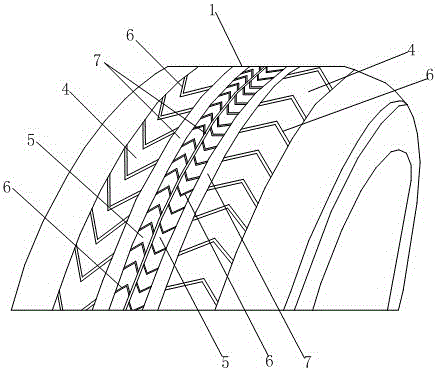

[0031] In this embodiment, four groups of side-by-side pattern surfaces are annularly arranged along the outer rubber layer. The pattern surfaces are respectively two groups of outer pattern surfaces 4 and two groups of inner pattern surfaces 5 arranged between the two groups of outer pattern surfaces 4. The pattern surface 4 and the inner pattern surface 5 are separated by several V-shaped grooves 6 to form several pattern blocks, and the explosion-proof layer 2 ...

Embodiment 2

[0035] The difference between this embodiment and embodiment 1 is that the rubber composed of perfluoroether rubber, nitrile rubber and natural rubber accounts for 50% of the total tread rubber.

Embodiment 3

[0037] The difference between this embodiment and Example 1 is that, in parts by weight, the tread rubber formula includes: 20 parts of perfluoroether rubber, 16 parts of nitrile rubber, 10 parts of natural rubber, 35 parts of reinforcing filler, accelerator 3.5 parts, 1.2 parts of vulcanizing agent, 1 part of vulcanization accelerator, and 0.8 parts of adhesion promoter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com