Tent special membrane

A film and tent technology, applied in the field of tents, can solve the problems of rough surface treatment, shortening the service life of tents, and inability to wash off with rainwater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

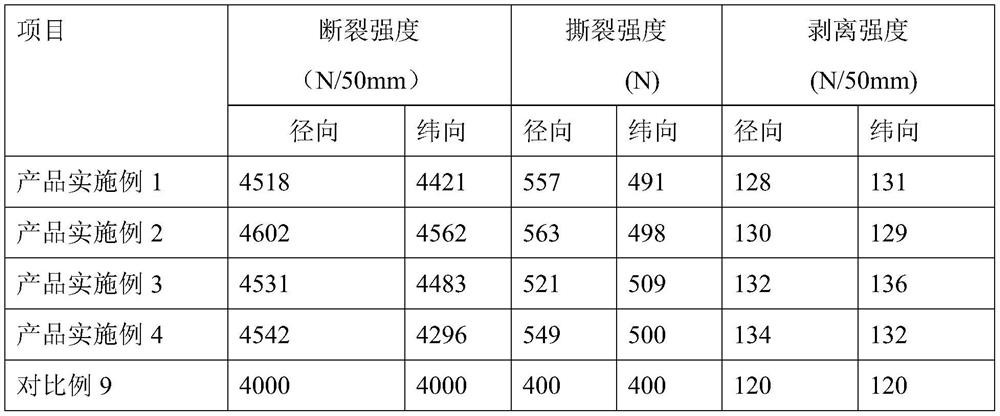

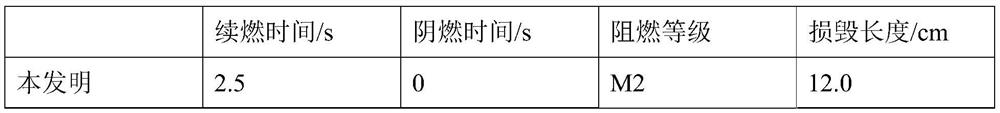

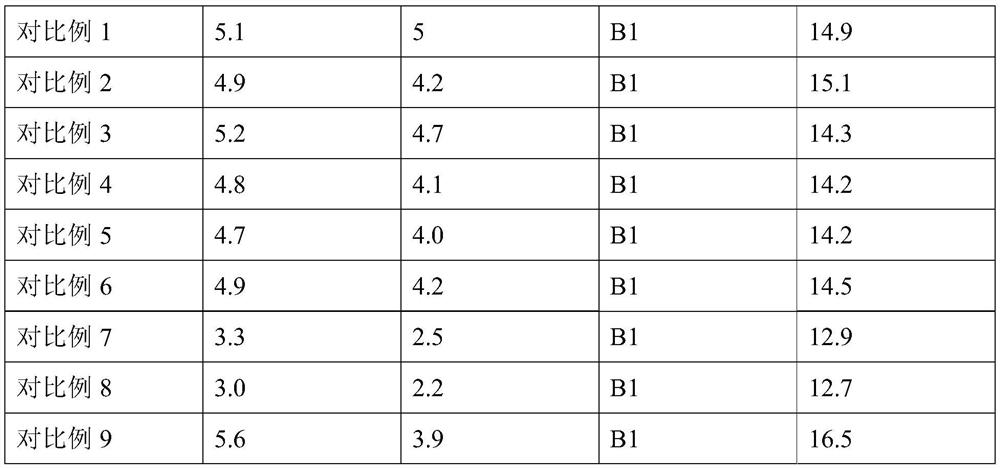

Examples

Embodiment 1

[0043] A special film material for tents, including a base fabric with a linear density of 2000D×2000D, the front and back of the base fabric are coated with a first coating, the surface of the first coating on the back of the base fabric is coated with a second coating on the back, The surface of the first coating on the front of the base cloth is coated with the second coating on the front, and the surfaces of the second coating on the back and the second coating on the front are both coated with a surface layer.

[0044] The first coating consists of the following components in parts by weight: 100 parts of polyvinyl chloride resin, 50 parts of dioctyl phthalate, 10 parts of tricresyl phosphate, 7 parts of antimony trioxide, epoxy fatty acid methyl ester 7 parts, 4 parts of epoxidized soybean oil, 3 parts of barium stearate;

[0045] The second coating on the back is composed of the following components in parts by weight: 100 parts of polyvinyl chloride resin, 55 parts of ...

Embodiment 2

[0051] A special film material for tents, including a base fabric with a linear density of 2000D×2000D, the front and back of the base fabric are coated with a first coating, the surface of the first coating on the back of the base fabric is coated with a second coating on the back, The surface of the first coating on the front of the base cloth is coated with the second coating on the front, and the surfaces of the second coating on the back and the second coating on the front are both coated with a surface layer.

[0052] The first coating consists of the following components in parts by weight: 100 parts of polyvinyl chloride resin, 40 parts of dioctyl phthalate, 8 parts of tricresyl phosphate, 5 parts of antimony trioxide, epoxy fatty acid methyl ester 5 parts, 3 parts of epoxidized soybean oil, 2 parts of lead dibasic phosphite;

[0053] The second coating on the back is composed of the following components in parts by weight: 100 parts of polyvinyl chloride resin, 50 par...

Embodiment 3

[0058] A special film material for tents, including a base fabric with a linear density of 2000D×2000D, the front and back of the base fabric are coated with a first coating, the surface of the first coating on the back of the base fabric is coated with a second coating on the back, The surface of the first coating on the front of the base cloth is coated with the second coating on the front, and the surfaces of the second coating on the back and the second coating on the front are both coated with a surface layer.

[0059] The first coating is composed of the following components in parts by weight: 100 parts of polyvinyl chloride resin, 60 parts of dioctyl phthalate, 12 parts of tricresyl phosphate, 10 parts of antimony trioxide, epoxy fatty acid methyl ester 10 parts, 5 parts of epoxidized soybean oil, 4 parts of tribasic lead sulfate;

[0060] The second coating on the back is composed of the following components in parts by weight: 100 parts of polyvinyl chloride resin, 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com