Preparation method of asymmetrically infiltrated high-collimation high-surface-viscosity fabric prepreg

A prepreg, asymmetric technology, applied in the field of additive manufacturing, which can solve the problem of high cost and achieve the effect of low-cost manufacturing, guaranteed alignment, and good surface adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

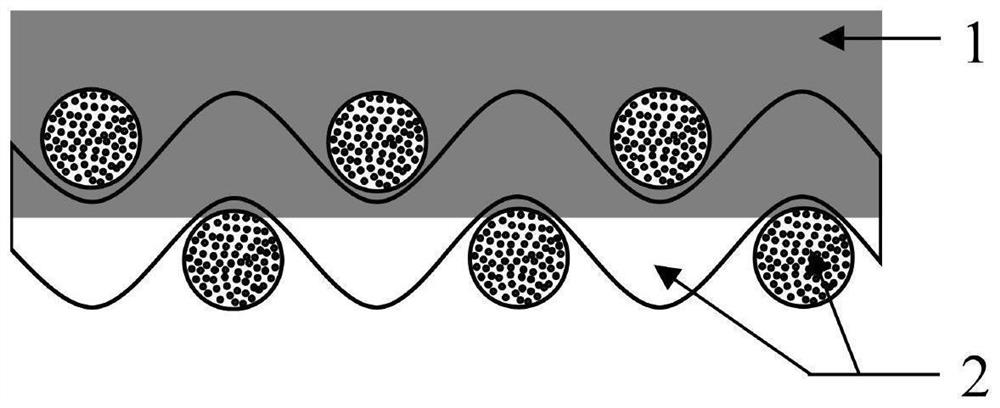

[0057] Use high-toughness medium-temperature curing epoxy resin as the matrix resin of the fabric prepreg, use EW301F glass fiber fabric as the reinforcement material, and the surface density of the fabric prepreg is 460g / m 2 , the width is 1000mm, and the surface density of glass fiber fabric is 285g / m 2 , The surface density of the resin film is 175g / m 2 . The preparation process of asymmetric infiltration high alignment and high surface tack fabric prepreg is discussed now.

[0058] (a) Preheat the medium-temperature curing epoxy resin and put it into the glue film machine, and prepare a surface density of 175g / m under the condition of the resin viscosity of 110Pa·s 2 (accounting for 38% of the mass content of the fabric prepreg) continuous resin film;

[0059] (b) Set the areal density to 285g / m 2 The EW301F fabric is led into the gap between the first pair of prepreg rollers through the unwinding device, and the infrared tracking deviation correction device is turned ...

Embodiment 2

[0064] High-toughness high-temperature curing epoxy resin is used as the matrix resin of the fabric prepreg, CF8611 carbon fiber fabric is used as the reinforcement material, and the surface density of the fabric prepreg is 327g / m 2 , the width is 1000mm, and the CF8611 fabric area density is 196g / m 2 , The surface density of the resin film is 131g / m 2 . The preparation process of asymmetric infiltration high alignment and high surface tack fabric prepreg is discussed now.

[0065] (a) Preheat the high-temperature cured epoxy resin and put it into the film machine, and prepare a continuous resin film with an area density accounting for 40% of the mass content of the fabric prepreg under the condition of a resin viscosity of 130 Pa s;

[0066] (b) Set the surface density to 196g / m 2 The CF8611 fabric is led into the gap between the first pair of prepreg rollers through the unwinding device, and the infrared tracking deviation correction device is turned on, and the deviation...

Embodiment 3

[0071] High tenacity bismaleimide resin is used as the matrix resin of the fabric prepreg, EW100A glass fiber fabric is used as the reinforcement material, and the surface density of the fabric prepreg is 182g / m 2 , the width is 1000mm, and the surface density of EW100A fabric is 100g / m 2 , The surface density of the resin film is 82g / m 2 . The preparation process of asymmetric infiltration high alignment and high surface tack fabric prepreg is discussed now.

[0072] (a) Preheat the bismaleimide resin and put it into the film machine, and prepare a continuous resin film with an area density accounting for 45% of the mass content of the fabric prepreg under the condition of a resin viscosity of 150 Pa s;

[0073] (b) Set the areal density to 100g / m 2 The EW100A fabric is guided into the gap between the first pair of prepreg rollers through the unwinding device, and the infrared tracking deviation correction device is turned on, and the deviation angle between the infrared t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com