Instant cuttlefish juice seasoning sauce and manufacturing method thereof

A production method and a technology for cuttlefish juice are applied in the field of ready-to-eat cuttlefish juice sauce and its production, which can solve the problem of low nutritional value and achieve the effects of easy to accept taste, increase stickiness, and increase oil brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

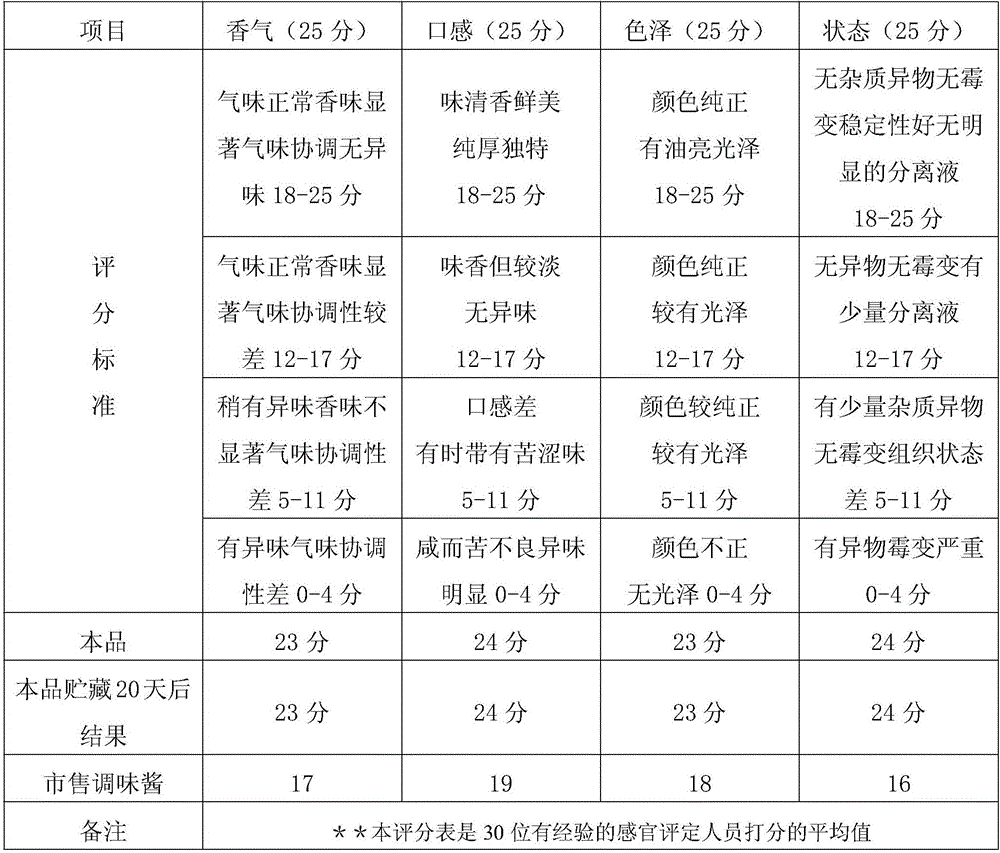

Image

Examples

Embodiment 1

[0024] After extracting the cuttlefish juice from the cuttlefish bag, it is filtered and boiled for preparation;

[0025] Specific production method:

[0026] (1) Pretreatment of vegetable juice; that is, 25.7 parts of onion, 5.5 parts of garlic, 5.5 parts of ginger, 5.5 parts of green pepper, 5.5 parts of carrot, and 18.5 parts of water are put into the juicer and crushed into fine particles of vegetable juice ;

[0027] (2) Hot pot: Pour 9.2 parts of olive oil and 9.2 parts of butter into the pot, heat it to 70-8 minutes at 40-50℃;

[0028] (3) Stir-fry: add vegetable juice and stir-fry until the vegetable water has almost evaporated;

[0029] (4) Boil: 3.7 parts of brandy, 0.7 parts of crushed black pepper, 5.5 parts of oyster sauce, 1.8 parts of cuttlefish juice, stirring constantly, and boiling for 20-40 minutes at 40-50°C;

[0030] (5) Thickening: add 3.7 parts of wet sweet potato powder to thicken, heat at 100°C, turn for 3-8 seconds to turn off the heat;

[0031] (6) Canning and ...

Embodiment 2

[0033] After extracting the cuttlefish juice from the cuttlefish bag, it is filtered and boiled for preparation;

[0034] Specific production method:

[0035] (1) Pretreatment of vegetable juice; that is, 24 parts of onion, 6 parts of garlic, 6.1 parts of ginger, 5 parts of green pepper, 6 parts of carrots, and 20 parts of water are put into the juicer and crushed into fine particles of vegetable juice ;

[0036] (2) Hot pot: Pour 8.4 parts of olive oil and 9 parts of butter into the pot, heat it at 40-50℃ to 70-8 minutes;

[0037] (3) Stir-fry: add vegetable juice and stir-fry until the vegetable water has almost evaporated;

[0038] (4) Boiling: 4 parts of brandy, 1 part of crushed black pepper, 4.5 parts of oyster sauce, 2 parts of cuttlefish juice, stirring constantly, and boiling for 20-40 minutes at 40-50℃;

[0039] (5) Thickening: Add 4 parts of wet sweet potato powder to thicken, heat at 100°C, turn for 3-8 seconds to turn off the heat;

[0040] (6) Canning and sterilization: Aft...

Embodiment 3

[0042] After extracting the cuttlefish juice from the cuttlefish bag, it is filtered and boiled for preparation;

[0043] Specific production method:

[0044] (1) Pretreatment of vegetable juice; that is, 23.5 parts of onion, 4.5 parts of garlic, 5 parts of ginger, 4 parts of green pepper, 5 parts of carrot, and 23 parts of water are put into the juicer and crushed into fine particles of vegetable juice ;

[0045] (2) Hot pot: Pour 10 parts of olive oil and 8 parts of butter into the pot, heat it to 70 to 80 minutes at 40-50℃;

[0046] (3) Stir-fry: add vegetable juice and stir-fry until the vegetable water has almost evaporated;

[0047] (4) Boil: 3 parts of brandy, 1.5 parts of crushed black pepper, 4.5 parts of oyster sauce, 3 parts of cuttlefish juice, stirring constantly, and boiling for 20-40 minutes at 40-50℃;

[0048] (5) Thickening: Add 5 parts of wet sweet potato powder to thicken, heat at 100°C, turn for 3-8 seconds to turn off the heat;

[0049] (6) Canning and sterilization:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com