Fragrant cigarette cartridge and fragrance suction device

A flavor and pod technology, which is applied in the field of heat-not-burn cigarettes, can solve the problems of insufficient atomization and the entry of e-liquid particles, so as to increase the choice of flavors, improve reliability, and overcome the effects of oral e-liquid inhalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

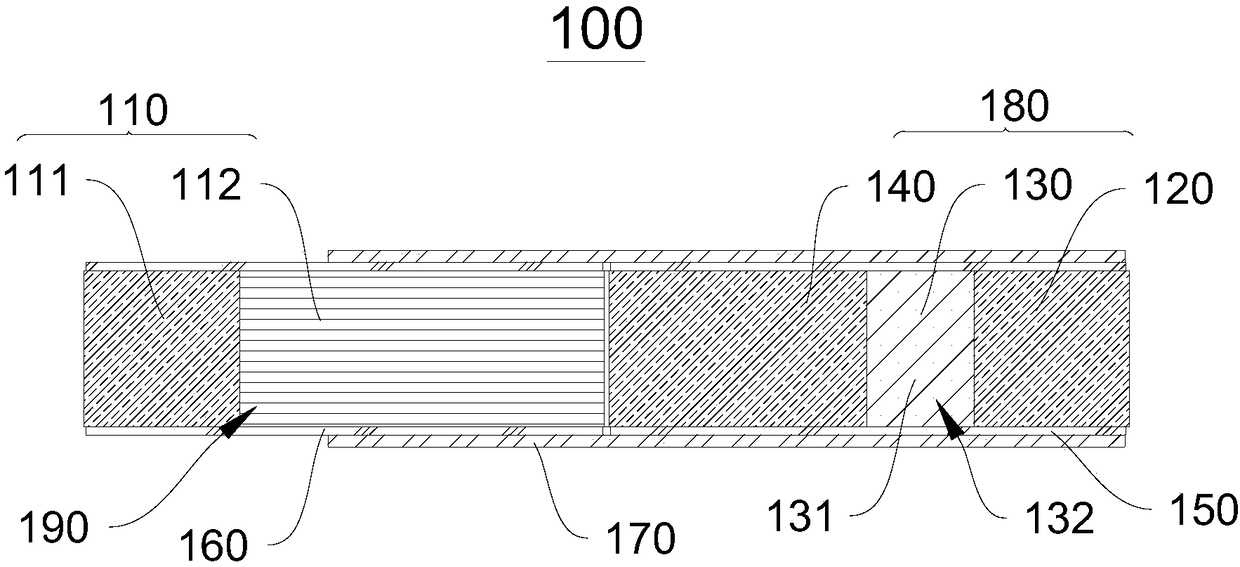

[0034] Such as figure 1 As shown, the flavored cartridge 100 includes a filter section 110, a second cavity base 140, a fragrance section 130, and a first cavity base 120. In this embodiment, the filter section 110 includes a filter section 111 and a flavoring filter section 112. , and the filter part 111 , the flavoring filter part 112 , the second cavity base 140 , the fragrance section 130 and the first cavity base 120 are sequentially connected coaxially. The aerosol atomized by the atomization part passes through the first cavity base 120, the fragrance section 130, the second cavity base 140 and the gas flow channel inside the filter section 110, and carries The fragrance emitted by the fragrance segment 130 .

[0035] Further, the flavoring filter part 112 and the filter tip part 111 are wrapped by the second forming paper 160 to form a binary composite filter rod 190, and the first cavity matrix 120, the spice segment 130 and the second cavity matrix 140 are wrapped b...

Embodiment 2

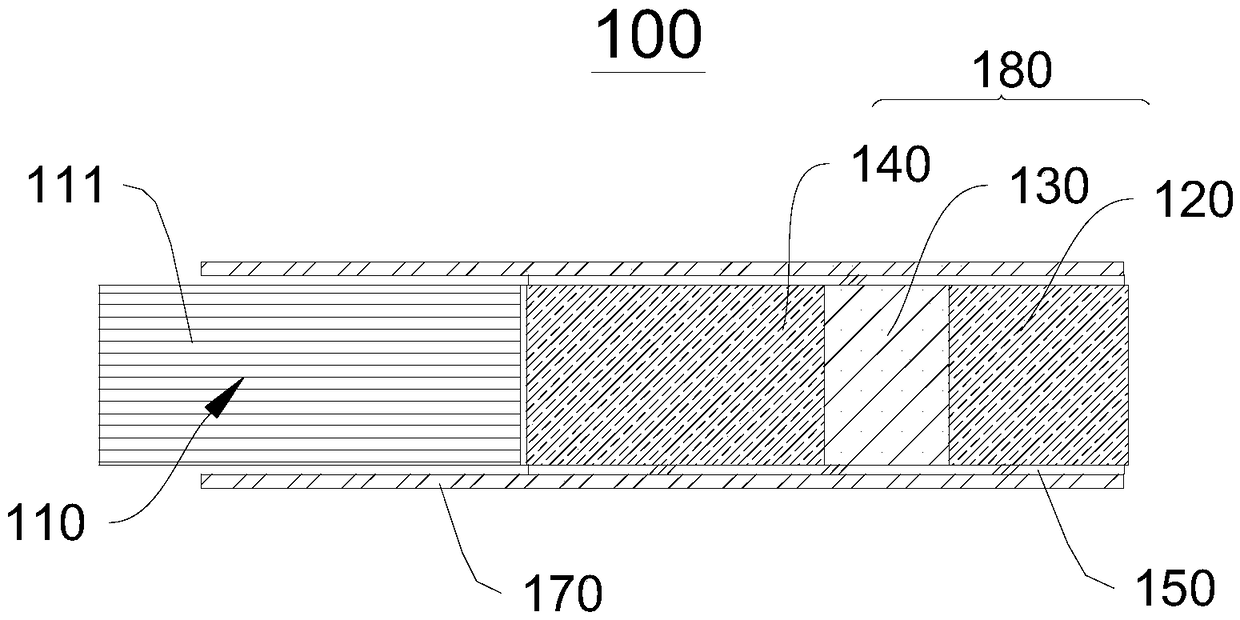

[0048] Such as figure 2 The structure of the flavored cartridge 100 provided in the illustrated embodiment 2 is basically similar to the structure of the flavored cartridge 100 in the embodiment 1, the difference is that the filter segment 110 in the embodiment 2 only includes the filter portion 111 and does not Contains fragrance filter unit 112 . Specifically, the first cavity matrix 120, the spice segment 130 and the second cavity matrix 140 are wrapped by the first forming paper 150 to form a three-dimensional cavity composite filter rod 180, and the filter part 111 and the three-component cavity composite filter rod 180 The flavored cartridge 100 in this embodiment is formed by the third forming paper 170 .

[0049] Further, the third forming paper 170 fully wraps the ternary cavity composite filter rod 180, partially or completely wraps the filter part 111 to form the flavored cartridge 100, or fully wraps the filter part 111, partially or completely wraps the ternary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com