Atomized smoke generating material for heat-not-burn product and preparation method of atomized smoke generating material

A heat-not-burn, product technology, applied in the preparation of tobacco, tobacco, application, etc., to achieve the effect of good smoking quality, soft and gentle smoke, and delicate smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing an atomized smoking material for heat-not-burn products, the method comprising the following steps:

[0032] S1, crushing unroasted green coffee beans and sieving to obtain coffee powder;

[0033] S2. Extracting and separating the coffee powder to obtain coffee extract and coffee extraction residue;

[0034] Coffee beans contain protein, fat and sugar. After the protein molecule is affected by some external physical and chemical factors, although the peptide chain of the molecule is not cleaved, its natural structure is changed / destroyed, resulting in changes in the chemical properties of the protein. When sugar encounters high temperature, it will catalyze the carbonization of protein, high temperature cracking of protein and fat, generate free radicals, and combine with each other to generate carcinogens such as benzopyrene. Using roasted coffee beans to conduct experiments, it was found that high-temperature roasting wil...

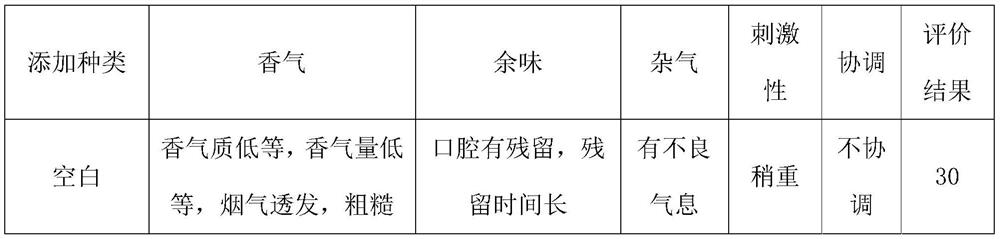

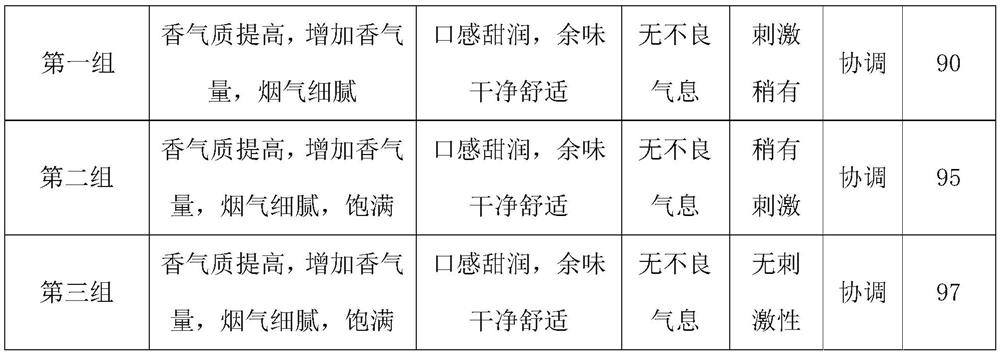

Embodiment 1

[0057] In this example, chlorogenic acid and caffeine are extracted and separated from green coffee beans using the above method, and then an atomized smoking material for heat-not-burn products is prepared. The raw materials for the preparation of the atomized smoking material and The usage of each raw material is as follows:

[0058] 6.7 parts of coffee extract, 300 parts of coffee extraction residue, 350 parts of tea base, 70.5 parts of glycerin, 171 parts of propylene glycol and 101.8 parts of additives;

[0059] The 6.7 parts of coffee extract include 1.7 parts of chlorogenic acid and 5 parts of caffeine according to parts by mass, and the additive is essence.

Embodiment 2

[0061] The difference between this embodiment and embodiment 1 is:

[0062] The raw materials for the preparation of the atomized smoking material and the consumption of each raw material are as follows:

[0063] 0.3 parts of chlorogenic acid, 1 part of caffeine, 180 parts of coffee extraction residue, 220 parts of tea base, 30 parts of glycerin, 150 parts of propylene glycol and 90 parts of essence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com