Bacillus subtilis and method for producing vanillin by using bacillus subtilis

A technology of Bacillus subtilis and vanillin, applied in the field of microorganisms, can solve the problems to be improved, and achieve the effects of improving the suction experience, maintaining the naturalness, and having abundant and easy-to-obtain raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Screening and isolation of embodiment 1 bacterial strain

[0053] Sampling: In a sterile operating bench, weigh 20g of Maotai-flavored Daqu by quartering method. After grinding the sample with a mortar, wash it with 180mL of normal saline, shake the incubator at 150rpm and mix for 30min.

[0054] Bacteria enrichment culture: after the water bath, absorb 5 mL of koji solution and inoculate it into the enrichment medium, and enrich the culture in a shaker at 37°C and 150 rpm for 24 hours.

[0055] Dilution and coating: after enrichment culture, pipette 1mL of bacterial suspension into a 9mL saline test tube to dilute. Pipette 100 μL to dilute to 10 -4 、10 -5 、10 -6 The bacterial suspension was spread on the plate isolation medium.

[0056] Isolation: Cultivate in a 37°C incubator for 24 hours, observe the colony shape after the cultivation, pick a single colony and inoculate it on the plate medium by streaking method to separate and purify.

[0057] For the specific...

Embodiment 2

[0058] Ferulic acid ferulic acid of embodiment 2 produces the fermentation method of vanillin

[0059] S1: Inoculate the preserved bacterial strain on the activation medium, and culture it statically at 35-40° C. for 12-24 hours.

[0060] S2: After the seed medium is inoculated with the strain, it is cultured for 12-24 hours under the culture conditions of a temperature of 35-40° C. and a rotational speed of 150 r / min to obtain a seed liquid.

[0061] S3: After the ferulic acid fermentation medium is inoculated with the seed solution, ferment for 100-150 hours under the culture conditions of a temperature of 35-40° C. and a rotation speed of 100-180 rpm.

[0062] Table 1 shows the activation medium and glucose fermentation medium required for the bioconversion of glucose to vanillin by the strain.

Embodiment 3

[0063] Example 3 strain producing vanillin ability test

[0064] In this experiment, the strains were preliminarily screened, and 24 strains with strong vanillin-producing ability were obtained. The specific results are shown in Table 2.

[0065] Table 2 Screening of higher yield strains

[0066]

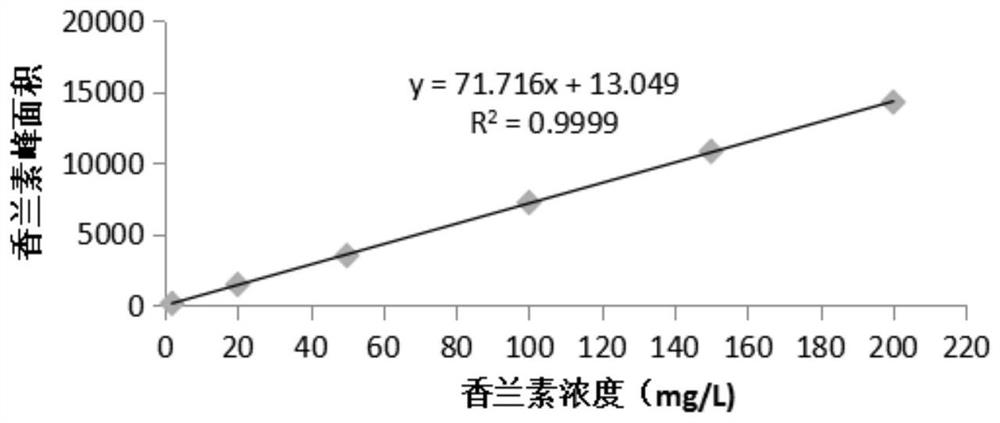

[0067] Take the vanillin content (x, mg / L) as the abscissa and OD280 (y) as the ordinate to draw the vanillin standard curve, see the results figure 1 . Depend on figure 1 It can be seen that the regression equation of the standard curve is y=71.716x+13.049, and the correlation coefficient R 2 = 0.9999. The vanillin content and the absorbance value showed a good linear relationship.

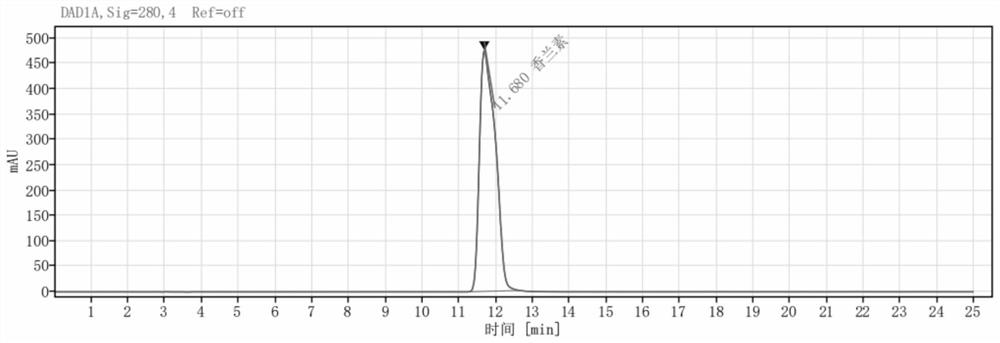

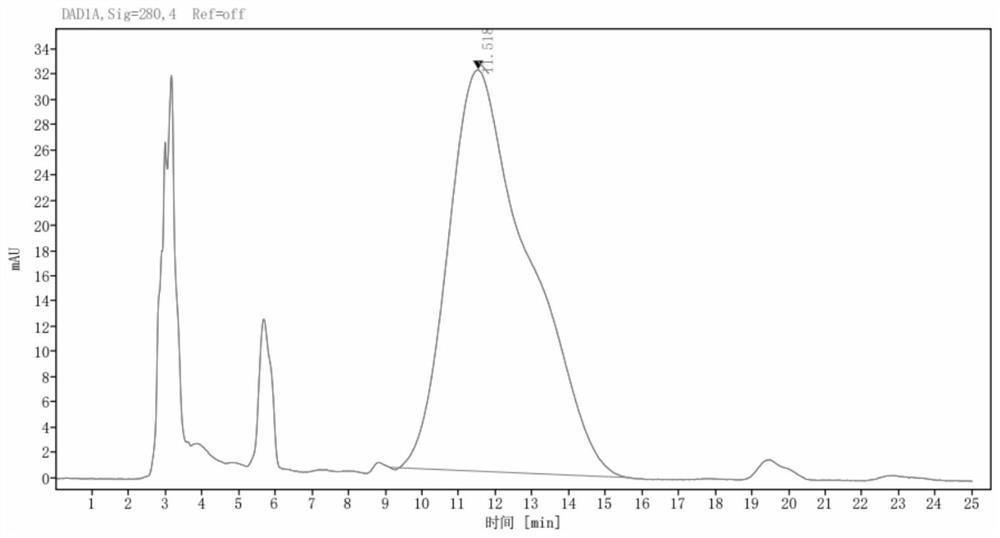

[0068] In this experiment, the HPLC detection of the vanillin standard was carried out with reference to the high-performance liquid chromatography method used by Zhao Jianfen et al. (05):332-333.). The resulting liquid chromatogram was figure 2 Shown, the retention time of vanillin standar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com