Heat-not-burn smoke cartridge with binary structure

A heat-not-burn, dual-structure technology, used in tobacco, cigar manufacturing, smoker's products, etc., can solve the problems of high flue gas temperature, small smoke volume, low smoke volume, etc. The effect of low flue gas temperature and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Example 1: The heat-not-burn pod with a binary structure of the present invention

[0074] The implementation mode of this embodiment is as follows:

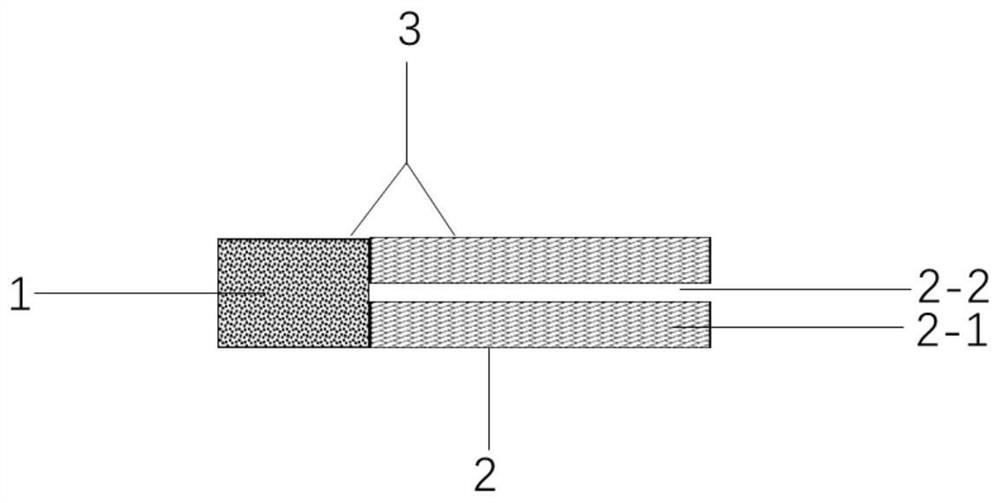

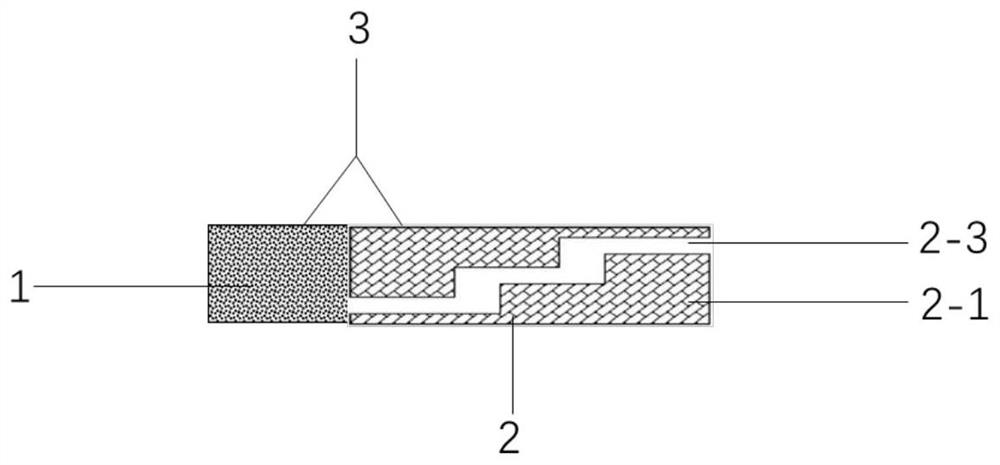

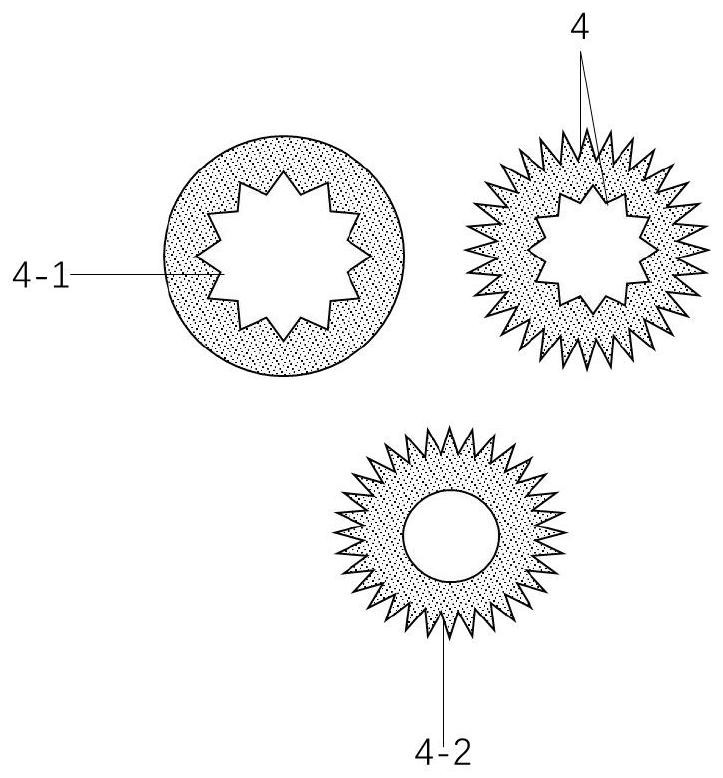

[0075] The heat-not-burn pod with a dual structure of the present invention is sequentially connected by the smoke-generating section 1 and the smoke-binding section 2, and is wrapped by the outer layer of cellulose paper sold by Yunnan Endian Technology Industry Development Co., Ltd. under the trade name Filter Rod Forming Paper The paper 3 is wrapped and rubbed together. The diameter of the smoking section and the smoke binding section are the same, and their roundness is 90.2%. The heat-not-burn pod is cylindrical with a length of 45mm and a diameter of 7mm; The length of the smoke-generating section is 12mm, and the length of the smoke-binding section is 33mm; wherein:

[0076] The smoking section is composed of a smoking material and a wrapping material layer wrapping the smoking material, wherein the smoking materi...

Embodiment 2

[0080] Example 2: The heat-not-burn pod with a binary structure of the present invention

[0081] The implementation mode of this embodiment is as follows:

[0082] The heat-not-burn pod with a binary structure of the present invention is sequentially connected by the smoking section 1 and the smoke binding section 2 through the aluminum foil composite paper outer wrapping paper 3 sold by Yunnan Endian Science and Technology Industry Development Co., Ltd. under the trade name of aluminum foil paper Wrapped and twisted, the smoke-generating section and the smoke-binding section have the same diameter, and their roundness is greater than 90.6%; the heat-not-burn pod is cylindrical with a length of 74mm and a diameter of 5mm; The length of the smoke section is 20mm, and the length of the smoke-binding section is 54mm; wherein:

[0083] The smoking section is composed of a smoking material and a wrapping material layer wrapping the smoking material, wherein the smoking material i...

Embodiment 3

[0086] Example 3: The heat-not-burn pod with a binary structure of the present invention

[0087] The implementation mode of this embodiment is as follows:

[0088] The heat-not-burn pod with a binary structure of the present invention is sequentially connected by the smoking section 1 and the smoke binding section 2 through a plastic film composite cellulose paper sold by Shanghai Weixi Biotechnology Co., Ltd. under the trade name of transparent forming paper. Layers of wrapping paper 3 are wrapped and rubbed together. The diameter of the smoking section and the smoke binding section are the same, and their roundness is greater than 91.2%. The heat-not-burn pod is cylindrical with a length of 73mm and a diameter of 6mm. ; The length of the smoke section is 48mm, and the length of the smoke binding section is 25mm; wherein:

[0089] The smoking section is composed of a smoking material and a wrapping material layer wrapping the smoking material, wherein the smoking material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com