Essence additive for temperature drop section of heating non-burning cigarette, preparation method and application of essence additive and heating non-burning cigarette

A heat-not-burn, additive technology, applied in the preparation of tobacco, application, essential oils/spice, etc., can solve the problems of difficulty in maintaining the uniformity and consistency of aroma, non-persistent aroma, inconsistent taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

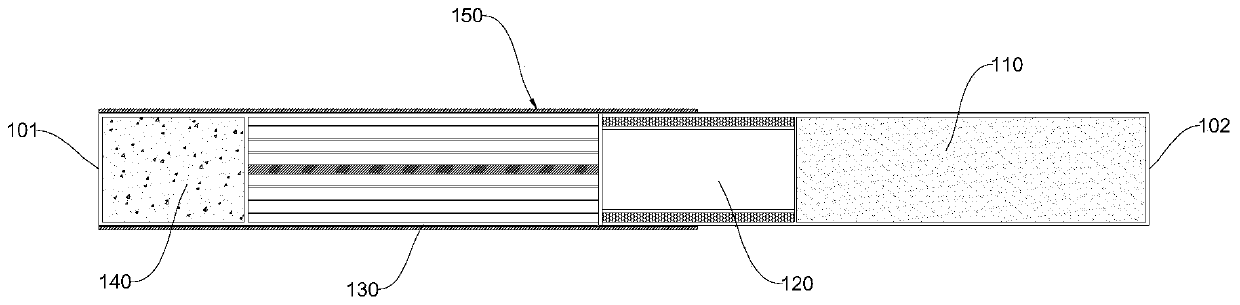

Image

Examples

preparation example Construction

[0035] The embodiment of the present invention also provides a method for preparing flavor additives used in the cooling section of heat-not-burn cigarettes, including: preparing the first flavor according to the extraction raw materials and extraction temperature corresponding to the first flavor, specifically, the first flavor The preparation process includes extraction, filtration and concentration. The extraction process can be distillation, leaching, molecular distillation, supercritical CO 2 Existing processes such as extraction method, strictly control the extraction temperature.

[0036] In some embodiments, the extraction process adopts a heating reflux extraction method; the extraction solvent is selected from water, ethanol, propylene glycol, methanol, acetone, petroleum ether, chloroform, ether, ethyl acetate, dichloroethane and dipropylene glycol At least one; preferably, the extraction solvent includes ethanol, water, ethyl acetate, and propylene glycol, and the...

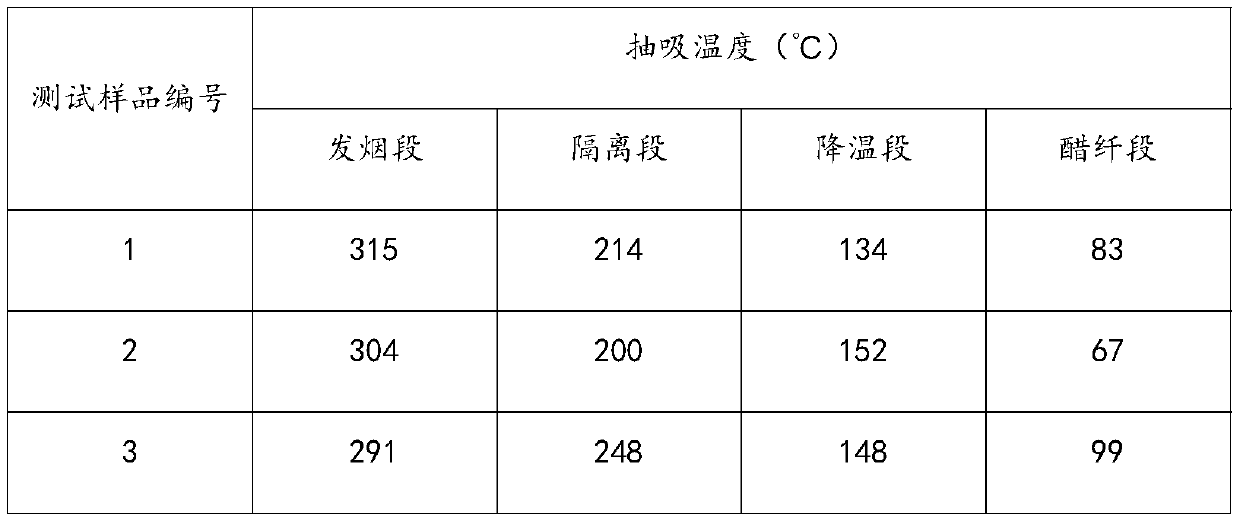

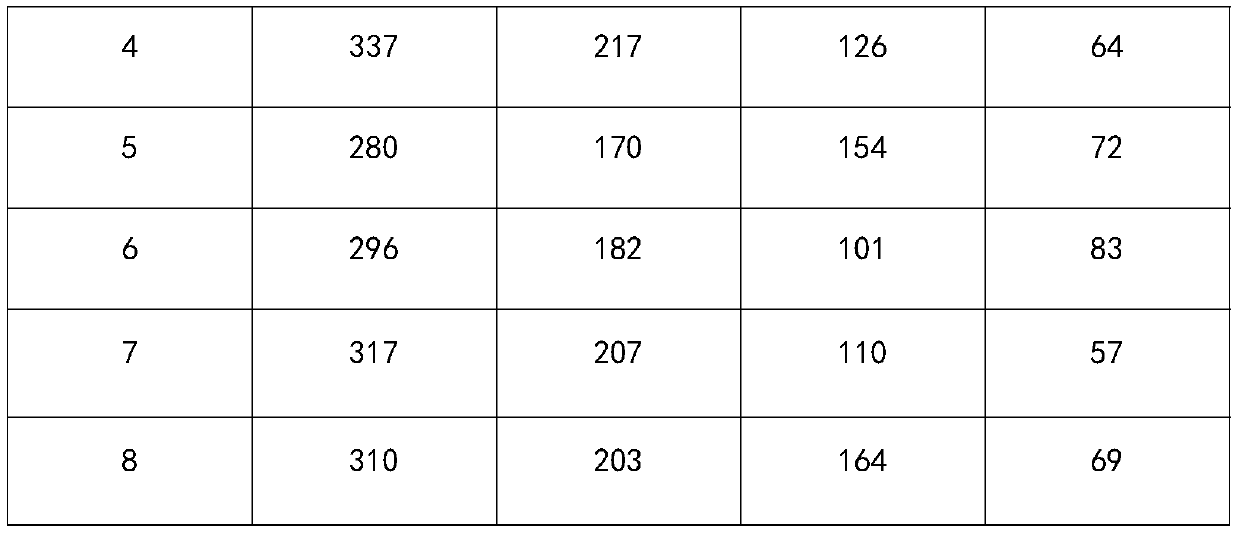

Embodiment 1

[0043] This embodiment provides a method for preparing flavor additives used in the cooling section of heat-not-burn cigarettes, which includes the following steps:

[0044] Preparation of the first flavor: Weigh 5g of dried pineapple, 2g of cinnamon, 5g of orange peel, 5g of fresh lemon, and 3g of dried ginger, and cut them into small pieces of 10×10mm; mix the chopped materials with 100g of the extract, and the extract is Methanol: ethyl acetate: water (mass ratio 3:1:1), the filtrate was collected after reflux extraction at 80°C for 3 hours, and then the water in the filtrate was removed by low-temperature concentration.

[0045] Configuration of essence additives: in parts by weight, take 0.1 part of first essence, 0.1 part of second essence (peppermint oil), 0.02 part of humectant (honey) and 8 parts of fixative (ambroxan) and mix Evenly, stand still for 24 hours and set aside.

[0046] Flavoring: Add the prepared flavoring additives to the cooling section by spraying, s...

Embodiment 2

[0048] This embodiment provides a method for preparing flavor additives used in the cooling section of heat-not-burn cigarettes, which includes the following steps:

[0049] Preparation of the first essence: Weigh 3g of bitter almonds, 3g of roses, 5g of fennel, 5g of cocoa, and 2g of licorice, and cut them into small pieces of 10×10mm; mix the chopped materials with 150g of the extract, which is ethanol: Water: propylene glycol (mass ratio: 2:4:2), the filtrate was collected after reflux extraction at 180°C for 3 hours, and then the water in the filtrate was removed by low-temperature concentration.

[0050] Configuration of flavor additives: by weight, get 50 parts of the first flavor, 50 parts of the second flavor (including 10 parts of hydroxyphenyl butanone, 10 parts of 2-3 dimethylpyrazine, 5 parts of methyl butyrate , 5 parts of ethyl butyrate, 10 parts of ethyl cinnamate, 10 parts of butyl cinnamate), 90 parts of solvent (including 30 parts of water, 30 parts of ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com