Method for controlling cigarette quality consistency of cigarette making machine

A cigarette machine, consistent technology, applied in the manufacture of cigarettes, tobacco, applications, etc., can solve the problems of cigarette quality differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

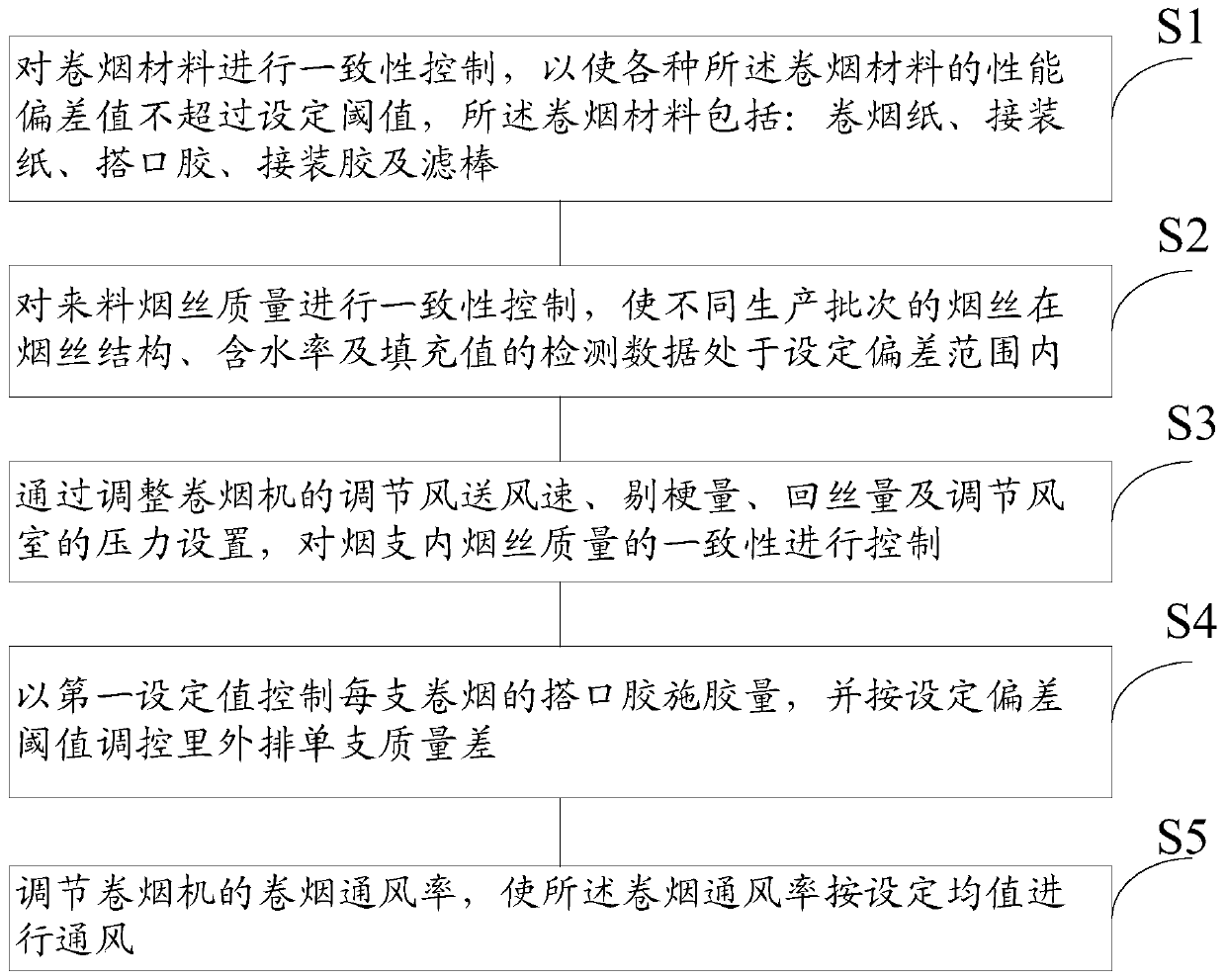

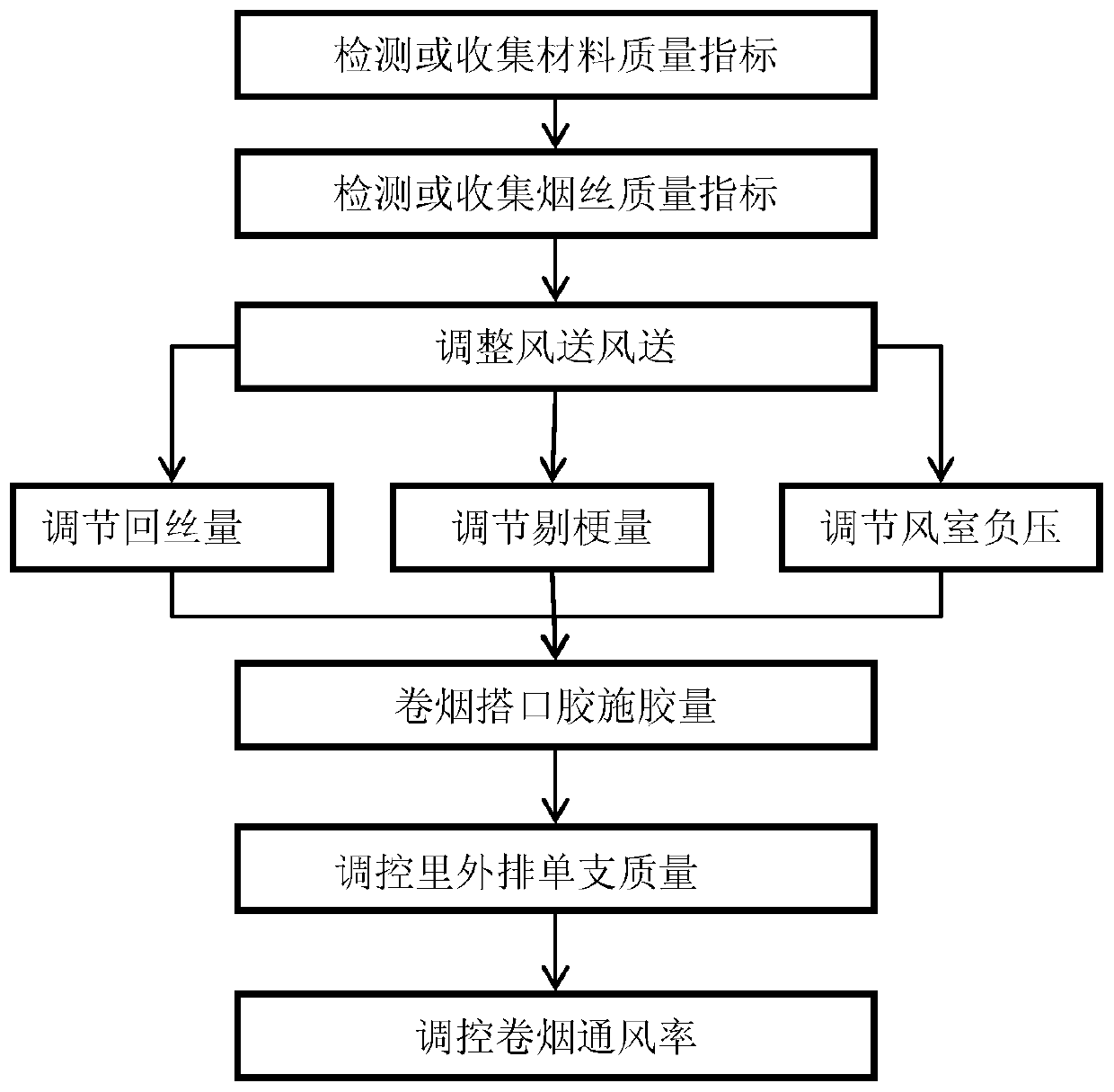

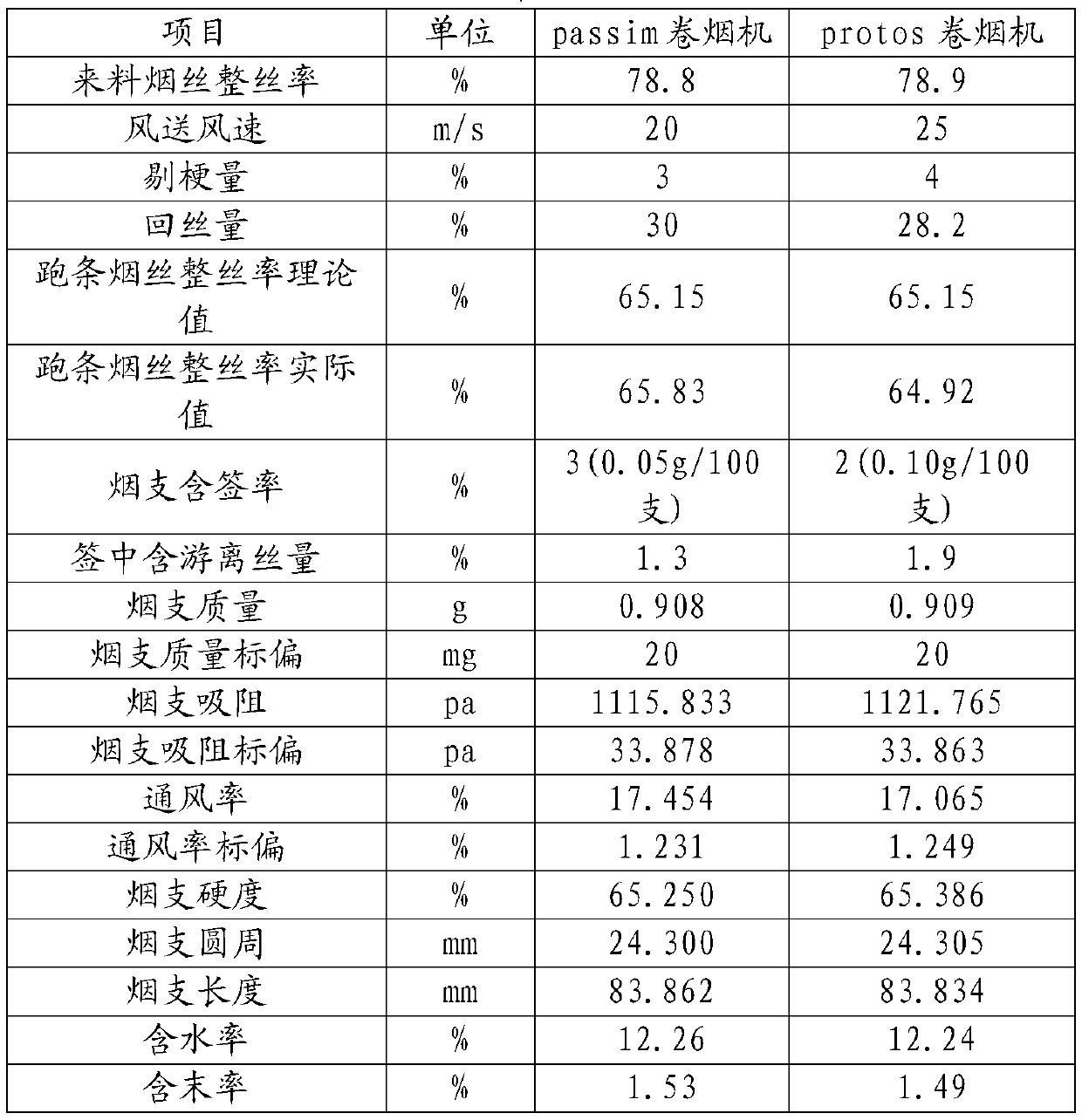

[0036] Aiming at the current problem of cigarette quality differentiation caused by different cigarette making machines, the present invention provides a method for controlling the consistency of cigarette quality of cigarette making machines, by controlling the quality consistency of cigarette materials and shredded tobacco, and by adjusting the air speed, wind speed, The amount of cut stems, the amount of shreds returned and the pressure setting of the air chamber are adjusted to realize the control of the quality of shredded tobacco. Solving the problem of cigarette quality differentiation among existing cigarette machines of different models can improve the consistency of cigarette quality, reduce raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com