Heated non-combustible cigarette cooling section and preparation method thereof

A heat-not-burn and cooling section technology, applied in tobacco, smoker’s supplies, applications, etc., can solve the problems of polylactic acid film shrinkage and melting, high smoke temperature, poor smoke uniformity, etc., to meet the needs of the heart and physiological requirements, reduce the temperature of flue gas, and improve the effect of smoking experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

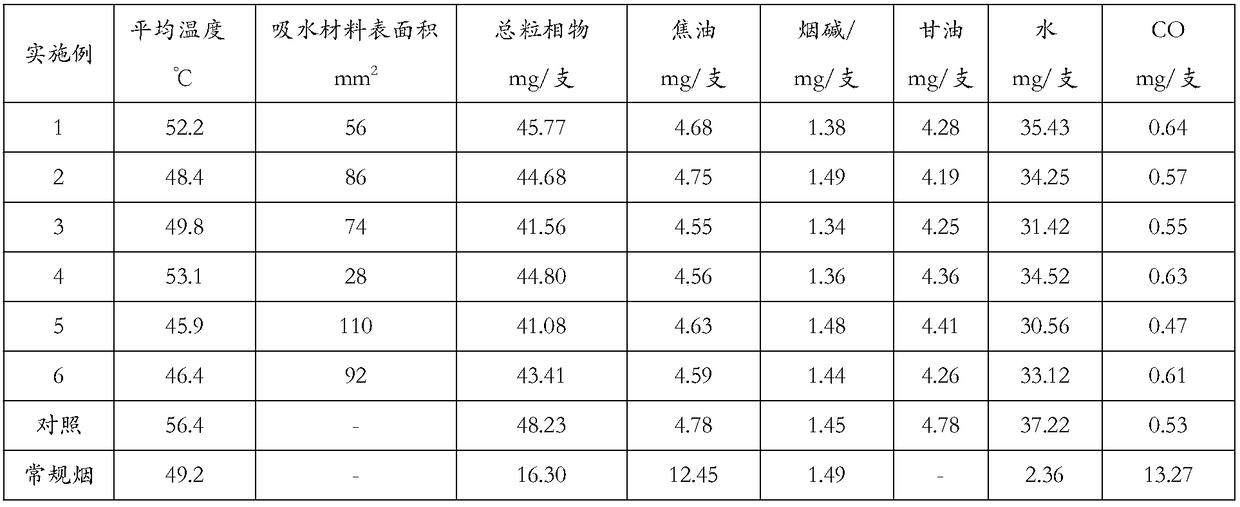

Embodiment 1

[0049] Embodiment 1: The cooling section of the heat-not-burn cigarette of the present invention

[0050] The implementation mode of this embodiment is as follows:

[0051] The heat-not-burn cigarette cooling section is composed of heat-insulating paper tubes and water-absorbing material particles in the tubes, wherein:

[0052] The water-absorbing material particles are spherical particles of starch derivative water-absorbing materials sold by Shanghai Yutao Industrial Co., Ltd. under the trade name of cross-linked starch; the surface area of the water-absorbing material particles is 56mm 2 The particle size of the water-absorbing material is 2.2 mm; the water-absorbing capacity of the water-absorbing material is 400 times of its water-absorbing material's own weight;

[0053] The heat-insulating paper tube is a heat-insulating paper tube with a circumference of 16mm made of corrugated paper sold by Wenzhou Heyue Packaging Co., Ltd. under the trade name paper tube, and two...

Embodiment 2

[0055] Example 2: The heating and non-burning cigarette cooling section of the present invention

[0056] The implementation mode of this embodiment is as follows:

[0057] The heat-not-burn cigarette cooling section is composed of heat-insulating paper tubes and water-absorbing material particles in the tubes, wherein:

[0058] The water-absorbing material particles are water-absorbing silica gel pentagonal particles sold by Qingdao Qingyang Silica Gel Co., Ltd. under the trade name color-changing silica gel; the surface area of the water-absorbing material particles is 86mm 2 The particle size of the water-absorbing material is 2.4mm; the water-absorbing capacity of the water-absorbing material is 1000 times the water content of the water-absorbing material itself;

[0059] The heat-insulating paper tube is a heat-insulating paper tube with a circumference of 22 mm made of corrugated paper sold by Wenzhou Heyue Packaging Co., Ltd. under the trade name paper tube, and one ...

Embodiment 3

[0061] Example 3: The cooling section of the heat-not-burn cigarette of the present invention

[0062] The implementation mode of this embodiment is as follows:

[0063] The heat-not-burn cigarette cooling section is composed of heat-insulating paper tubes and water-absorbing material particles in the tubes, wherein:

[0064] The water-absorbing material particles are sponge capsule-shaped particles sold under the trade name nano-sponge by Puyang Enward New Material Company; the surface area of the water-absorbing material particles is 74mm 2 The particle size of the water-absorbing material is 1.0 mm; the water-absorbing capacity of the water-absorbing material is 10 times the water content of the water-absorbing material itself;

[0065] The heat-insulating paper tube is a heat-insulating paper tube with a circumference of 20mm made of corrugated paper sold by Wenzhou Heyue Packaging Co., Ltd. under the trade name paper tube, and three of the above-mentioned water-absorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com